JUMO dTRON 316 JUMO dTRON 308

JUMO dTRON 308 JUMO dTRON 304

J dTRON 304

J dTRON 308

J dTRON 316

Compact Controller with program function

B 70.3041.1

Operating Instructions

06.05

Contents

1

1.1

2

3

3.1

3.2

3.3

4

4.1

4.2

5

6

6.1

6.2

6.3

6.4

6.5

6.6

7

Preface ……………………………………………………… 3

Scope of delivery …………………………………………………………… 3

Identifying the instrument version ………………. 4

Mounting …………………………………………………… 5

Preparation ……………………………………………………………………. 5

Fitting in position, Type 703042/43/44 ……………………………… 5

Fitting in position, Type 703041 ……………………………………….. 5

Electrical connection …………………………………. 6

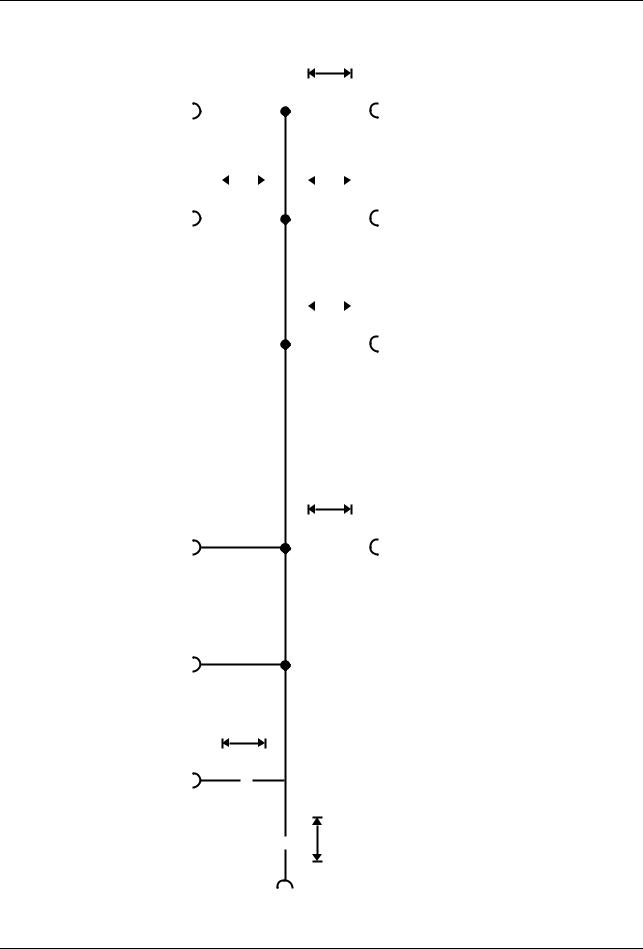

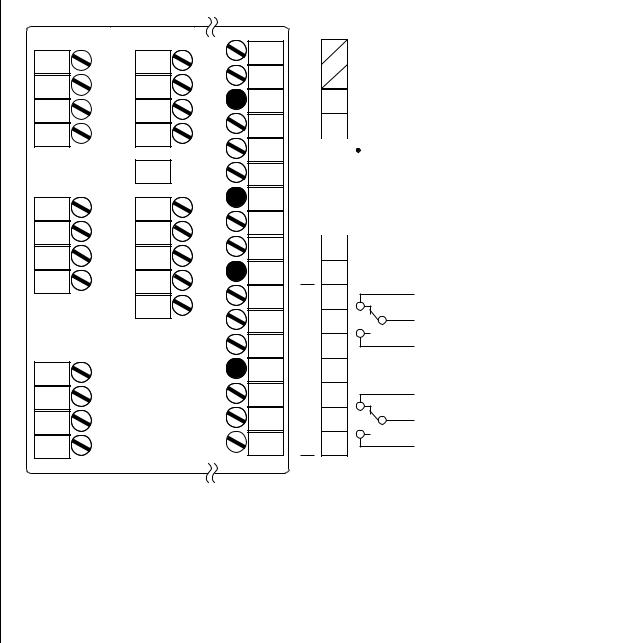

Connection diagram for Type 703041 ………………………………. 6

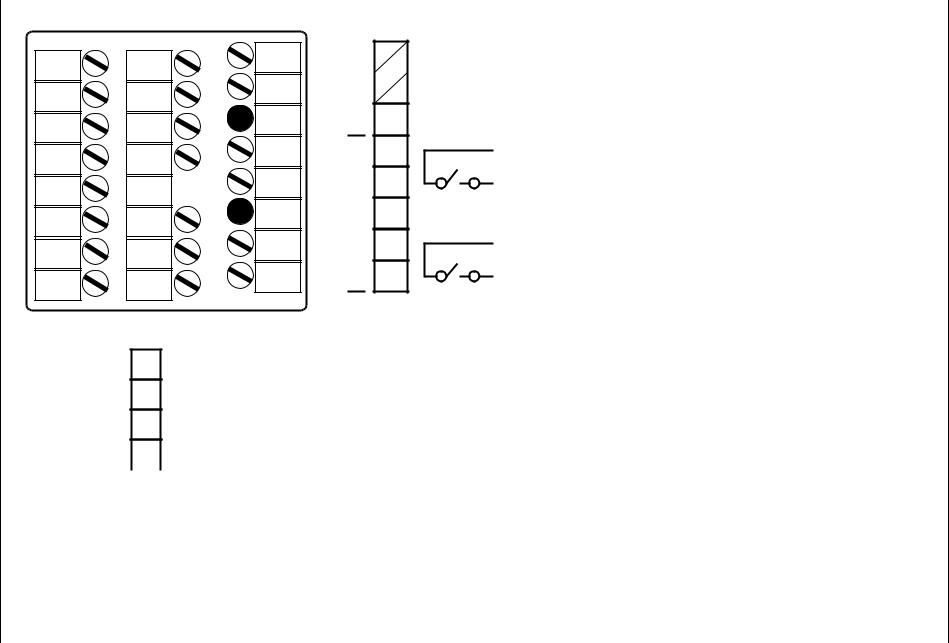

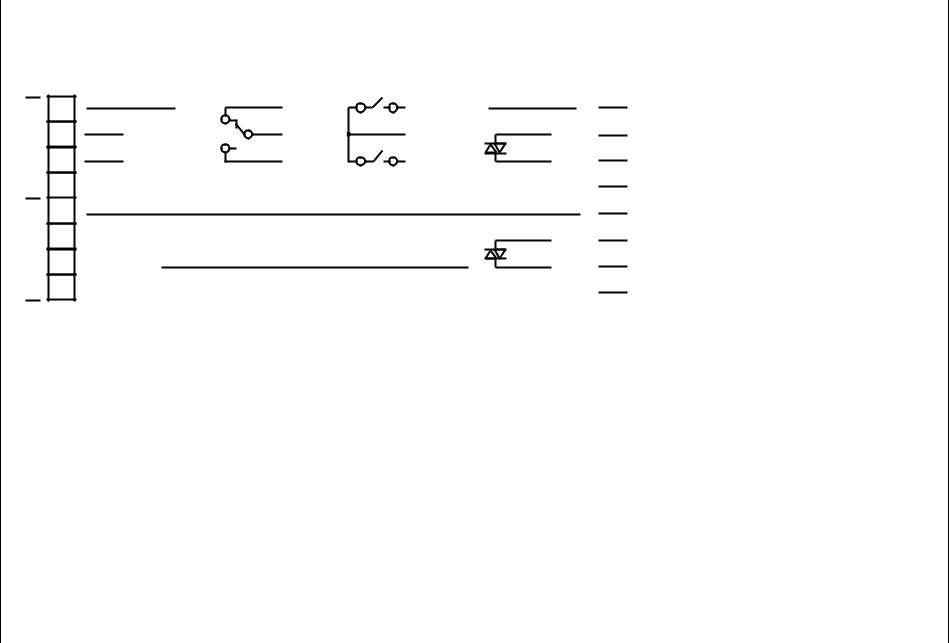

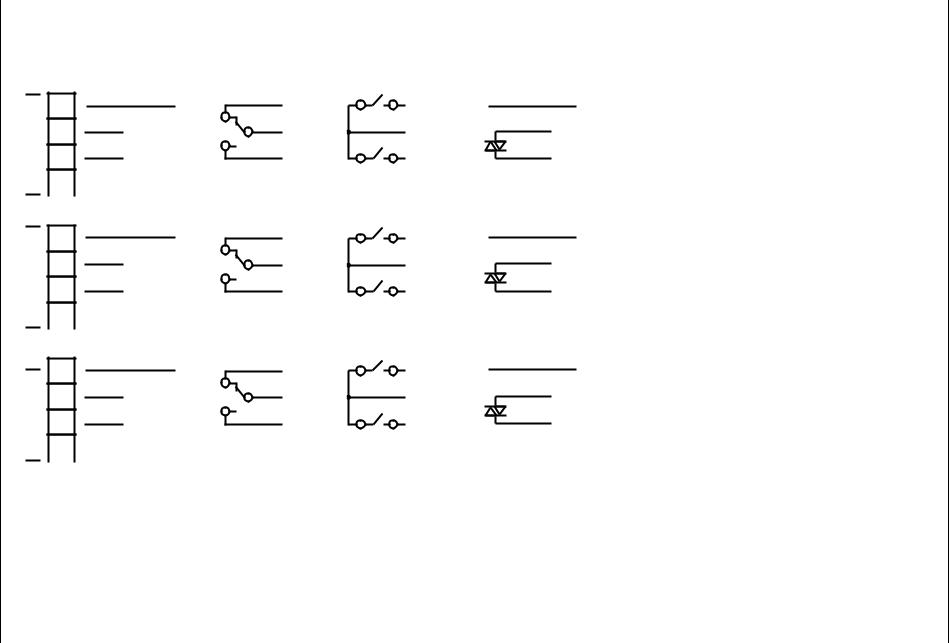

Connection diagram for Type 703042/43/44 ……………………… 7

Displays and keys ……………………………………… 8

Operation ………………………………………………….. 9

Level concept ………………………………………………………………… 9

Level inhibit …………………………………………………………………. 10

Entering values …………………………………………………………….. 10

Entering times ……………………………………………………………… 11

Operation of the fixed-setpoint controller ………………………… 12

Operation of the program controller ……………………………….. 13

Operator level “OPr” ………………………………… 14

8 Parameter level “PArA” ……………………………. 15

9 Configuration level “ConF” ………………………. 16

9.1

9.2

9.3

9.4

9.5

Analog inputs “InP” ………………………………………………………. 16

Controller “Cntr” …………………………………………………………… 17

Generator “Pro” ……………………………………………………………. 17

Outputs “OutP” ……………………………………………………………. 18

Display “diSP” ……………………………………………………………… 19

10 Autotuning ………………………………………………. 20

11 Alarms …………………………………………………….. 21

1 Preface

1 Preface

H

These brief operating instructions only cover those actions that are essential for starting up the controller.

Gray rastering v

The factory settings for the instrument as delivered are shown on a gray background.

The complete configuration options can be found in the comprehensive Operating Manual B 70.3041.0 on the CD, or can be downloaded from http://www.jumo.net

1.1

Scope of delivery

— 1 controller

— seal

— mounting brackets

— brief operating instructions

— 1 CD with comprehensive operating instructions and

!

setup program as a demo version

3

2 Identifying the instrument version

2 Identifying the instrument version

Meaning of the number code on the nameplate

:

Basic type

703041 JUMO dTRON 316, 48 mm x 48 mm format

!

incl. 1 analog input, 2 relay outputs and 2 binary inputs or 2 logic outputs

703042 JUMO dTRON 308, 48 mm x 96 mm format (portrait format)

!

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

703043 JUMO dTRON 308, 96 mm x 48 mm format (landscape format)

!

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

703044 JUMO dTRON 304, 96 mm x 96 mm format

!

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

Basic type extensions

1 Basic type 1

8

9

Standard, with factory settings

Programming to customer specification

Logic outputs (2 are available as standard)

1 0 / 12 V

2 0 / 18 V

Type of option slots

0 not used

1 Analog input 2 (universal)

2 Relay (changeover)

3 2 relays (n.o. make contacts)

4 Analog output

5 2 binary inputs

6 Solid-state relay 1 A

7 RS422/485 interface

8 Profibus-DP interface

Supply

2 3 110 — 240 V AC -15/+10 %, 48 — 63 Hz

2 5 20 — 53 V AC/DC, 48 — 63 Hz

Extra codes

0 0 0 none

2 1 4 Math and logic module

2 1 7 Ratio controller

2 1 8 Difference controller

2 1 9 Humid ity controller

4

703041 / 1 8 1 – 0 0 0 – 2 3 / 0 0 0 , 0 0 0

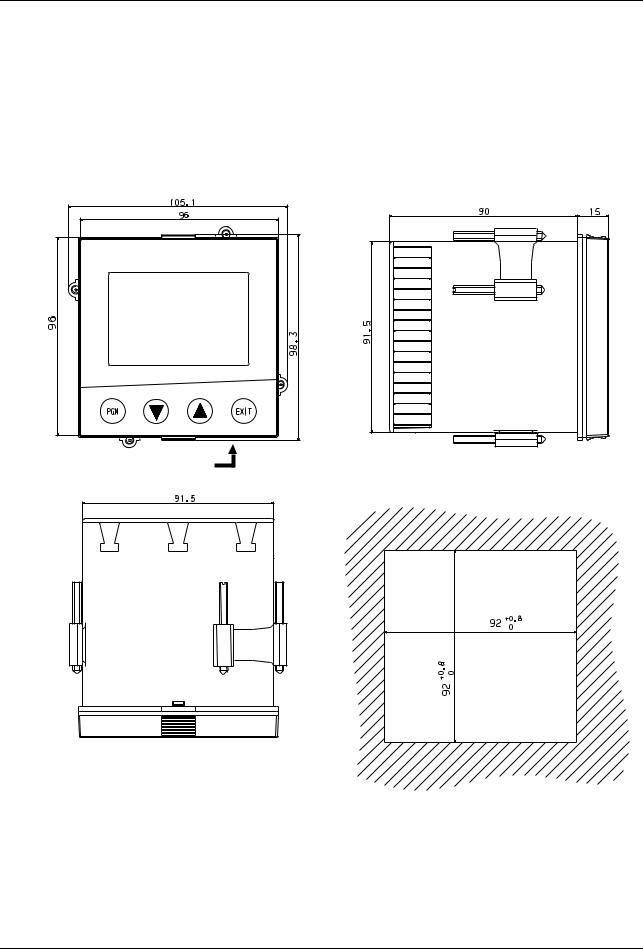

3 Mounting

3 Mounting

3.1

Preparation

Type

703041

dTRON Panel cut-out

316, in 48 mm x 48 mm format 45

+0.6

x 45

+0.6

mm

703042/43 308, in 48 mm x 96 mm format

(portrait)/(landscape)

703044

45

+0.8 x 92

+0.8

mm

304, in 96 mm x 96 mm format 92

+0.8

x 92

+0.8

mm

3.2

Fitting in position, Type 703042/43/44

h Fit the seal that is supplied onto the instrument body.

h Insert the controller from the front into the panel cut-out.

h From behind the panel, slide the mounting brackets into the guides on the sides of the housing.

!

The flat faces of the mounting brackets must lie against the housing.

h Push the mounting brackets up to the back of the panel, and tighten them evenly with a screwdriver.

3.3

Fitting in position, Type 703041

h Fit the seal that is supplied onto the instrument body.

h Insert the controller from the front into the panel cut-out.

h From the back of the panel, push the mounting frame onto the instrument body and press it against the back of the panel, compressing the springs, until the latches snap into the notches provided and it is firmly fixed in position.

5

4 Electrical connection

4 Electrical connection

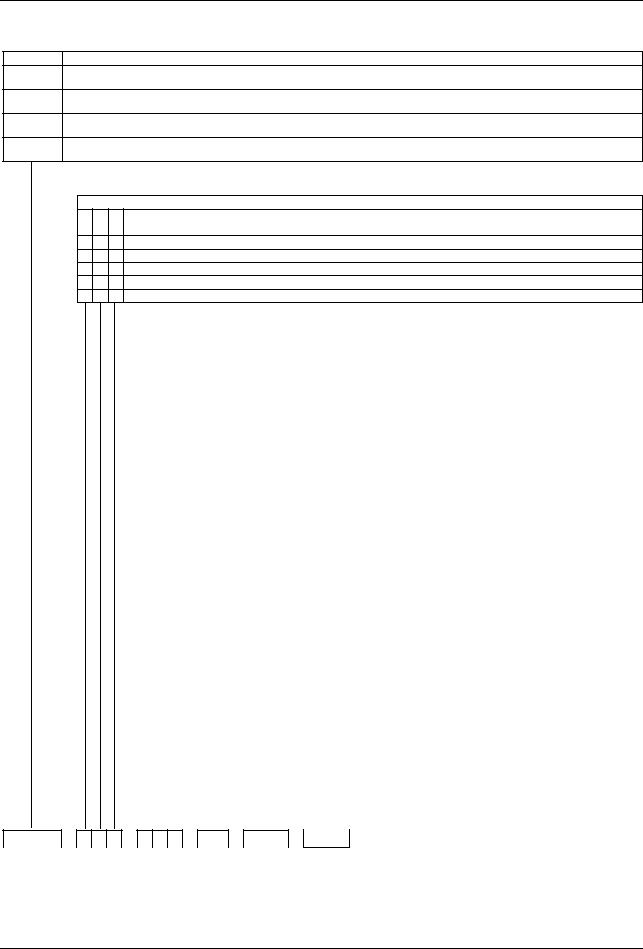

4.1

Connection diagram for Type 703041

6

4 Electrical connection

4.2

Connection diagram for Type 703042/43/44

7

8

5 Displays and keys

5 Displays and keys

(1)

(2)

(3)

(6)

(5)

(4)

PGM

EXIT

(1) 7-segment display (factory setting: process value)

four-digit, red, decimal place is configurable

!

(automatic adjustment on display overflow)

(2) Active setpoint (factory setting: SP1)

SP1, SP2, SP3, SP4 (SP=setpoint); green;

(3) 7-segment display (factory setting: setpoint)

four-digit, green, decimal place is configurable; also used for operator prompting (display of parameter and level symbols)

(4) Keys

(5) Indication

yellow, for

— switch status of the

binary outputs 1 — 6

!

— ramp/program function is active

— manual operation is active

(6) 16-segment display + dim. units

two-digit, green; for the unit °C/°F and symbols for h, min, %

Different values can also be visualized on the display.

v see the comprehensive operating manual on the CD

6 Operation

6.1

Level concept

The diagram below shows the three instrument levels.

6 Operation

H

Time-out

If no key is pressed for 30 sec, the instrument returns to normal display.

9

6 Operation

6.2

Level inhibit

The access to the individual levels can be inhibited by entering a code number.

h Press

P

and

D

simultaneously for >5 sec to enter the code.

1

2

Code

0

3

Operator level Parameter level Configuration level

enabled enabled enabled enabledenabled inhibited enabledinhibited inhibited inhibitedinhibited inhibited h Alter code with

P

(display blinks) h Enter code with

I

and

D h Return to normal display with

X

or automatically after approx. 30 sec

6.3

Entering values

When entries are made within the levels, the parameter symbol is shown in the lower display.

Select parameter

Alter parameter

P

I

I

I I I I I I I I I I I I I I I I I I

II II II II II II II

II

I

I

D h Select parameter with I or D h Change to the entry mode with P (lower display blinks) h Alter value with I and D!

The value alters dynamically with the duration of the key stroke. h Accept the setting with P or automatically after 2 sec h or h Cancel entry with X.!

The value is not accepted.

10

6 Operation

6.4

Entering times

When entering times (e.g. time of timer), the time unit is shown in addition.

Select

!

parameter

Alter

!

parameter

P

I

I

I I I I I I I I I I I I I I I I I I

II II II II II II II

II

I

I

D

The highest time unit of the display is shown for the unit.

For example, if “h” is shown for the hour, then the time format for the value is hh:mm.

h Select parameter with I or D h Change to the entry mode with P (lower display blinks) h Alter value with I and D!

The value alters dynamically with the duration of the key stroke. h Accept the setting with P or automatically after 2 sec or h Cancel entry with X.!

The value is not accepted.

11

6 Operation

6.5

Operation of the fixed-setpoint controller

H

The fixed-setpoint controller will only function if

— the fixed-setpoint controller function has been configured ( Fnct = 0)

Normal display Manual mode

h Alter the present setpoint with

I

and

D

The value is accepted automatically.

The controller output appears in the lower display. The hand symbol and the unit “%” light up in addition.

h Alter the output with

I

and

D

In the case of a modulating controller, the actuator is opened or closed using the keys.

The output entry on a changeover is configurable.

h Return to the normal display with X

(press for more than 2 seconds)

12

6 Operation

6.6

Operation of the program controller

H

The program controller will only function if

— the program controller function has been configured ( Fnct = 1 …4)

— the program setpoints (SPP1 … SPP8) and!

segment times (tP 1 … tP have been entered

Normal display Program is running

!

(the symbol for ramp appears)

Alter setpoint

h Alter the present setpoint with

I

and

D

The controller controls to the present setpoint.

(The value is accepted automatically after 2 sec.)

Program pause

When the program is paused, the lower display blinks.

The program is canceled in the event of a power failure.

13

7 Operator level “OPr”

7 Operator level “OPr”

Process data ProC

Symbol Meaning

SP 1 Setpoint 1 (editable)

SP 2 Setpoint 2 (editable)

SP 3 Setpoint 3 (editable)

SP 4 Setpoint 4 (editable)

SPr

InP1

Ramp setpoint (only if configured)

Measurement of analog input 1

Measurement of analog input 2 (only if available) InP2

F1

F2 y

Calculated result of math formula 1 (only if available)

Calculated result of math formula 2 (only if available)

Output trun trES t1 t2

Program run time (only with program controller/generator)

Residual program time (only with program controller/generator)

Timer: time 1 (only if configured)

Timer: time 2 (only if configured)

User data USEr (through the setup program only)!

Any parameter (up to eight) can be displayed and edited here by using the setup program.

Program data Pro (only with program controller/generator)!

A program with up to eight segments is defined here, via the segment setpoints

SPP1 … SPP8 and segment times tP 1 … tP 8.

14

8 Parameter level “PArA”

8 Parameter level “PArA”

Two parameter sets, PAr1 und PAr2, can be stored.

Parameter

Proportional band 1 a

Proportional band 2 b

Derivative time c

Reset time d

Symbol Value range

Pb 1

Pb 2 dt rt

0 … 9999 °C/°F

0 … 9999 °C/°F

0 … 9999 s

0 … 9999 s

Actuator time tt

Cycle time 1 tt 5 … 3000 s

CY 1 0.0 … 999.9 s

Cycle time 2

Contact spacing

Switching differential 1

Switching differential 2 e

Factory setting

0 °C/°F

0 °C/°F

80 s

350 s

60 s

20 s

CY 2 0.0 … 999.9 s db

20 s

0.0 … 999.9 °C/°F 0 °C/°F

HYS1

HYS2

0.0 … 999.9 °C/°F 1 °C/°F

0.0 … 999.9 °C/°F 1 °C/°F

Working point

Output limiting (max.)

Output limiting (min.) y0 y1 y2

-100 … +100 %

0 … 100 %

-100 … +100 %

0 %

100 %

-100 % a. with Pb1/2=0, the controller structure is not effective; depending on the display configuration, these values are shown with the corresponding decimal places b. for controller output 2 (with 3-state controllers) c. with dt=0, the controller has no differential action (e. g. PI controller) d. with rt=0, the controller has no integral action (e. g. PD controller) e. for controllers with Pb1/2=0

15

9 Configuration level “ConF”

9 Configuration level “ConF”

Depending on the equipment level of the instrument, individual parameters or groups of parameters are switched out of display.

Analog selector

!

With some parameters, you can choose from a series of analog signals. The list below gives you an overview of the selection options.

0 no function

!

1 Analog input 1

!

2 Analog input 2

!

3 Process value (controller)

!

4 Setpoint (controller)

!

5 Ramp end value

6 Program setpoint

!

13 Controller output level

!

14 Controller output 1

!

15 Controller output 2

9.1

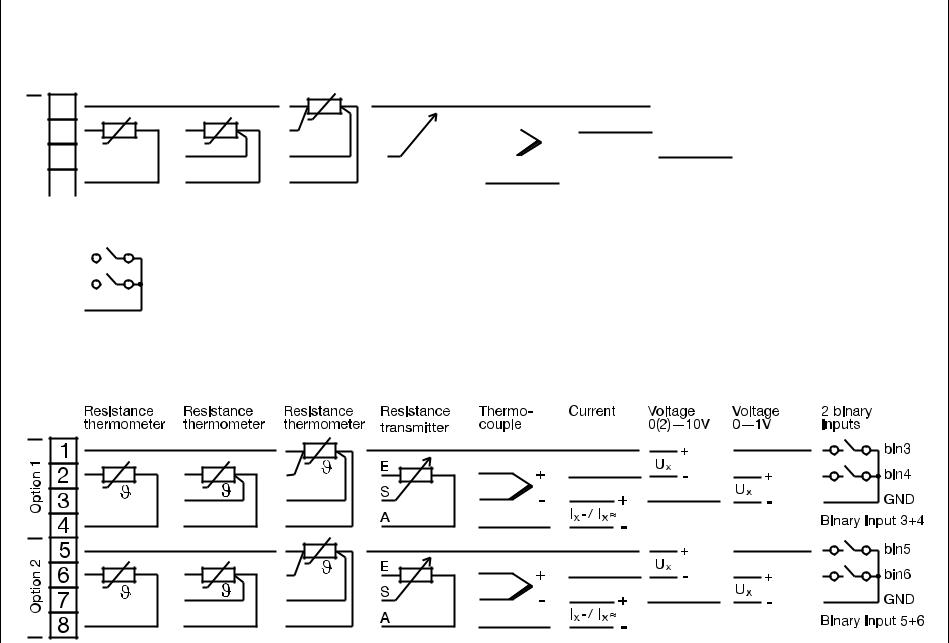

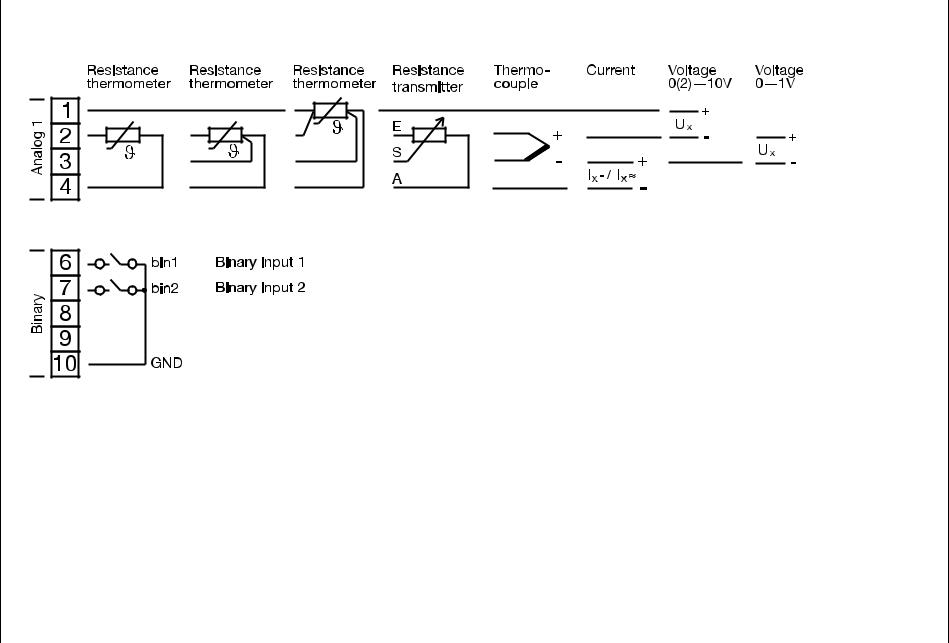

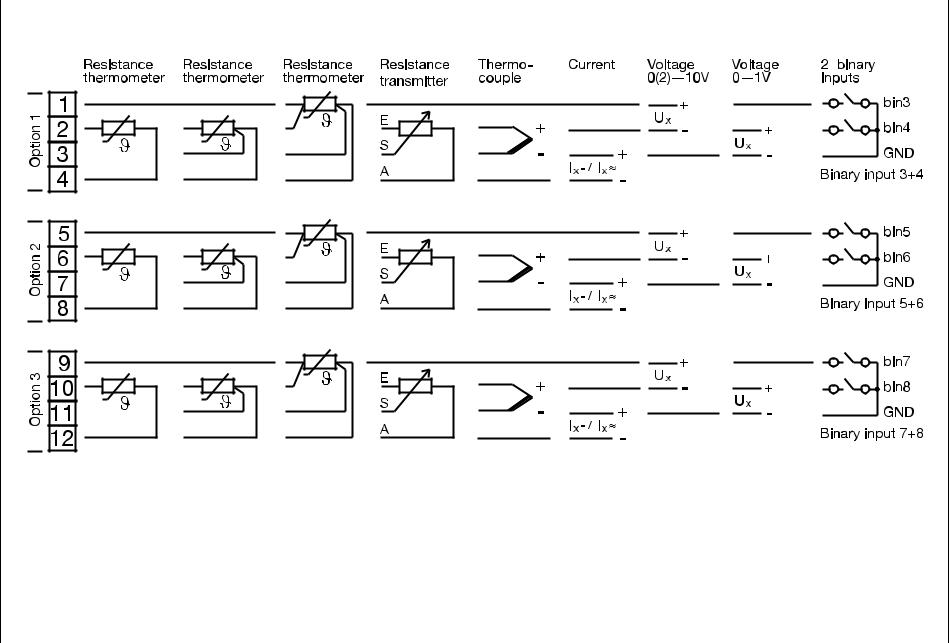

Analog inputs “InP”

r InP1 Analog input 1 r r InP2 Analog input 2 r

Parameter Symbol Value range

Sensor type

SEnS

Linearization

Lin

Measurement offset

OFFs

Display start

SCL

Display end

SCH

Factory settings are shown bold.

0 … 1 … 11

0 … 1 … 18

-1999 … 0 … +9999

-1999 … 0 … +9999

-1999 … 100 … +9999

Sensor type

0 no function

1 Resistance thermometer in

!

3-wire circuit

2 Resistance thermometer in

!

2-wire circuit

3 Resistance thermometer in

!

4-wire circuit

4 Thermocouple

5 Resistance transmitter

6 Heater current 0 — 50 mA AC

7 0 — 20 mA

8 4 — 20 mA

9 0 — 10 V

10 2 — 10 V

11 0 — 1 V

16

9 Configuration level “ConF”

Linearization

0 Linear

1 Pt100

2 Pt500

3 Pt1000

4 KTY11-6

5 Thermocouple type C

6 Thermocouple type D

7 Thermocouple type E

8 Thermocouple type T

9 Thermocouple type J

10 Thermocouple type U

11 Thermocouple type L

12 Thermocouple type K

13 Thermocouple type S

14 Thermocouple type R

15 Thermocouple type B

16 Thermocouple type N

17 Thermocouple W3Re-W26Re

18 customized linearization r In12 Analog input 1 and 2 general r

Parameter

Temperature unit

Sampling cycle time

Symbol Value range

Unit

CycL

0 … 1 (0=°C, 1=°F)

0 … 3 (0=50 ms; 1=90 ms; 2=150 ms;

3=250 ms)

Factory settings are shown bold.

9.2

Controller “Cntr”

Parameter

Controller type

Control action

Symbol Value range

CtyP

CAct

0 no function

1 Two-state controller

2, 3 Three-state, modulating controller

4 Continuous controller

0 … 1

!

(0=direct (cooling); 1=inverse (heating))

Factory settings are shown bold.

9.3

Generator “Pro”

Parameter

Function

Symbol Value range

Fnct

0 Fixed-setpoint controller

1 Ramp function

2 Program controller

3 Program generator

4 Hot-channel controller

Factory settings are shown bold.

17

9 Configuration level “ConF”

9.4

Outputs “OutP”

Numbering of the outputs

Standard: Relay 1 = output 1; relay 2 = output 2; logic output 1 = output 3;

!

Slot

logic output 2 = output 4

Plug-in board with

!

1 analog output

Plug-in board with

1 binary output

!

Plug-in board with

2 binary outputs

!

Option 1

Option 2

Option 3

Output 5

Output 6

Output 7

Output 5

Output 6

Output 7

Output 5+8

Output 6+9

Output 7+10 r Analog outputs OutA r Output 5 — 7 Out5…Out7 r

Parameter

Function

Signal type

Symbol Value range

Fnct

SiGn

Analog selector

switched off

0 … 2 … 3 (0 = 0 —10 V; 1 = 2 — 10 V;

!

2 = 0 — 20 mA; 3 = 4 — 20 mA)

Zero point

OPnt

End value

End

Factory settings are shown bold.

-1999 … 0 …+ 9999

-1999 … 100 …+ 9999

18

9 Configuration level “ConF”

r Binary outputs OutL r Output 1 — 10 Out1 … Out0 r

Function

0 no function

1 Controller output 1

16 Limit comparator 4

17 Control contact 1

2 Controller output 2 18 Control contact 2

3 — not used19 Control contact 3

4 — not used20 Control contact 4

5 Binary input 1 21 Logic formula 1

6 Binary input 2

7 Binary input 3

8 Binary input 4

9 Binary input 5

10 Binary input 6

11 Binary input 7

12 Binary input 8

13 Limit comparator 1

14 Limit comparator 2

15 Limit comparator 3

22 Logic formula 2

23 Timer 1 active

24 Timer 2 active

25 “Program active” signal

26 Program end signal

27 Tolerance limit signal

28 Manual mode on/off

29 Binary marker

30 Address value (setup)

31 always “active”

9.5

Display “diSP”

r

Parameter

Decimal point

Brightness

Symbol Value range

dEcP

0 … 2 (0 = no decimal place; 1 = one;

!

2 = two))

BriG

Factory settings are shown bold.

0 … 5 (0 = bright)

19

10 Autotuning

10 Autotuning

The autotuning facility can be used to automatically adapt the controller parameters to the process.

The autotuning function determines the controller parameters for a PID controller or, if dt=0 is set, for a PI controller in a closed control loop.

h Start with

I

and

D

(press simultaneously for >2 sec)

“tUnE” is shown blinking in the green display

I

I

I I I I I I I I I I I I I I I I I I

II II II II II II II

II

I

h Cancel with

I

and

D

(press simultaneously).

H

— The more sluggishly the process responds to setpoint changes, the longer the autotuning procedure will take.

— This involves determining the controller parameters rt, dt, Pb1, Pb2,

Cy1, Cy2, dF and accepting them automatically after the end of tuning.

20

11 Alarms

11 Alarms

Display

-1999

(blinking!)

9999

(blinking!)

All displays are on; lower 7-segment display is blinking

PrOF

OPt

Cause

Underrange for the value being displayed.

Overrange for the value being displayed.

Clear faults check/rectify/replace

Is the medium to be measured within the range

(too hot — too cold?)

Check probe for probe break / short-circuit.

Check the probe connection and the terminals.

Check the cable.

Watchdog or power-on triggers initialization (reset).

PROFIBUS error

Replace controller if the initialization takes longer than 5 sec.

Can be suppressed by setting the PROFIBUS address to “0.

Hardware configuration error Check which option boards are installed in the slots.

Overrange / underrange covers the following events:

!

— probe break / short-circuit

!

— measurement is outside the controllable range for the probe connected

!

— display overflow

Displaying the software version

h Display version with

P

and

I

(press simultaneously).

21

22

11 Alarms

H

Technical data has changed as follows:

Measuring accuracy resistance thermometer Pt100 2-wire

Sensor lead resistance

Measuring input for standard signals

Resistance transmitter

Supply voltage for 2-wire transmitter voltage

Electrical safety

«!0,4% max. 30

# per lead for 3-wire or 4-wire circuit min.100

#, max. 4k# electrically isolated, not stabilized

30V DC with no load

23V at 30mA load to EN 61 010, Part 1 overvoltage category II, pollution degree 2 for type 703041 with power supply AC/DC connect to SELV and PELV only

JUMO GmbH & Co. KG

Street adress:

Moltkestraße 13 — 31

!

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

!

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone:

Fax:

+49 661 6003-0

+49 661 6003-607

!

e-mail: [email protected]

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

!

Harlow, Essex CM20 2TT, UK

Phone: +44 1279 635533

!

Fax: +44 1279 635262 e-mail: [email protected]

Internet: www.jumo.co.uk

JUMO PROCESS CONTROL INC.

885 Fox Chase, Suite 103

!

Coatesville PA 19320, USA

Phone: 610-380-8002

!

1-800-554-JUMO

!

Fax: 610-380-8009 e-mail: [email protected]

Internet: www.JumoUSA.com

JUMO dTRON 304/308/316

Compact Controller with program function

Type 703043

|

Type 703041 |

Type 703042 |

Type 703044 |

B 70.3041.0

Operating Manual

2010-04-30/00442056

)Please read this operating manual before commissioning the instrument. Keep the manual in a place which is accessible to all users at all times.

Your comments are appreciated and may help us in improving this manual.

All necessary settings are described in this operating manual. Manipulations not described in the manual or expressly forbidden will jeopardize your warranty rights. Please contact the nearest subsidiary or the head office, should you encounter problems.

This manual is valid from instrument software version 192.02.05. It appears by simultaneously pressing the

When accessing the inner parts of the unit and returning modules, assemblies or components, Eplease observe the regulations accordings to EN 61340-5-1 and EN 61340-5-2 „Protection of elec-

trostatic sensitive devices“. Only use ESD packaging for transport.

Please note that we cannot accept any liability for damage caused by ESD.

ESD=Electro Static Discharge

|

Contents |

||

|

1 |

Introduction |

7 |

|

1.1 |

Description ………………………………………………………………………………………. |

7 |

|

1.2 |

Typographical conventions ………………………………………………………………. |

8 |

|

2 |

Identifying the instrument version |

9 |

|

2.1 |

Type designation ……………………………………………………………………………… |

9 |

|

2.2 |

Scope of delivery ……………………………………………………………………………. |

10 |

|

2.3 |

Accessories …………………………………………………………………………………… |

10 |

|

3 |

Mounting |

11 |

|

3.1 |

Mounting site and climatic conditions …………………………………………….. |

11 |

|

3.2 |

Dimensions ……………………………………………………………………………………. |

11 |

|

3.2.1 |

Type 703044 ……………………………………………………………………………………. |

11 |

|

3.2.2 |

Type 703042/43 ……………………………………………………………………………….. |

12 |

|

3.2.3 |

Type 703041 …………………………………………………………………………………… |

12 |

|

3.3 |

Side-by-side mounting …………………………………………………………………… |

13 |

|

3.4 |

Fitting in position ……………………………………………………………………………. |

13 |

|

3.5 |

Removing the controller module …………………………………………………….. |

14 |

|

4 |

Electrical connection |

15 |

|

4.1 |

Installation notes ……………………………………………………………………………. |

15 |

|

4.2 |

Electrical isolation ………………………………………………………………………….. |

16 |

|

4.3 |

Connection diagrams ……………………………………………………………………… |

17 |

|

4.3.1 |

Type 703041 ……………………………………………………………………………………. |

17 |

|

4.3.2 |

Type 703042/43/44 ………………………………………………………………………….. |

20 |

|

4.3.3 |

Termination resistor for the RS422/485 serial interface …………………………. |

24 |

|

4.3.4 |

Connection of the PROFIBUS-DP connector ………………………………………. |

24 |

|

Contents |

||

|

5 |

Operation |

25 |

|

5.1 |

Displays and controls …………………………………………………………………….. |

25 |

|

5.2 |

Level concept ………………………………………………………………………………… |

26 |

|

5.3 |

Level inhibit ……………………………………………………………………………………. |

27 |

|

5.4 |

Entries and operator prompting ……………………………………………………… |

28 |

|

5.5 |

Fixed-setpoint controller (ex-factory) ………………………………………………. |

29 |

|

5.6 |

Program controller …………………………………………………………………………. |

30 |

|

5.6.1 |

Entering programs ……………………………………………………………………………. |

30 |

|

5.6.2 |

Operation ……………………………………………………………………………………….. |

32 |

|

5.6.3 |

Shifting the program profile ……………………………………………………………….. |

33 |

|

6 |

Operator level |

35 |

|

7 |

Parameter level |

37 |

|

8 |

Configuration |

39 |

|

8.1 |

Analog inputs “InP” ………………………………………………………………………… |

41 |

|

8.1.1 |

Customized fine tuning …………………………………………………………………….. |

43 |

|

8.2 |

Controller “Cntr” ……………………………………………………………………………. |

45 |

|

8.3 |

Generator “Pro” ……………………………………………………………………………… |

47 |

|

8.4 |

Limit comparators “LC” ………………………………………………………………….. |

50 |

|

8.5 |

Outputs “OutP” ………………………………………………………………………………. |

54 |

|

8.6 |

Binary functions “binF” …………………………………………………………………… |

56 |

|

8.7 |

Display “diSP” ………………………………………………………………………………… |

59 |

|

8.8 |

Timer “tFct” …………………………………………………………………………………… |

61 |

|

8.9 |

Interfaces “IntF” …………………………………………………………………………….. |

62 |

|

9 |

Tuning (optimization) |

63 |

|

9.1 |

Autotuning (self-optimization) …………………………………………………………. |

63 |

|

9.2 |

Check of the tuning ………………………………………………………………………… |

66 |

|

Contents |

||

|

10 |

Extra codes |

67 |

|

10.1 |

Math and logic module …………………………………………………………………… |

67 |

|

10.2 |

Difference, humidity or ratio controller ……………………………………………. |

67 |

|

11 |

Retrofitting of modules |

69 |

|

12 |

Appendix |

71 |

|

12.1 |

Technical data ………………………………………………………………………………… |

71 |

|

12.2 |

Alarm messages …………………………………………………………………………….. |

74 |

|

13 |

Index |

75 |

Contents

1 Introduction

1.1 Description

The controller series consists of four freely programmable instruments in different DIN formats for controlling temperature, pressure and other process variables.

As a temperature controller TR1 according to EN 14597 the devices are used in heatgenerating plants to control the temperature of liquids or gases (mode of action: 1B).

The high-contrast, multicolor LCD display for process value, setpoint and operator prompting contains two four-digit 7-segment displays, two single-character 16segment displays, display of the active setpoints, six status indicators, and displays for the unit, ramp function and manual operation.

Just four keys on the front panel are needed for operation, parameterization and configuration. The instruments can be used as 2-state, 3-state, modulating or continuous controllers. The controller software includes a program or ramp function, parameter set changeover, two autotuning (self-optimization) procedures, a math and logic module, as well as 4 limit comparators.

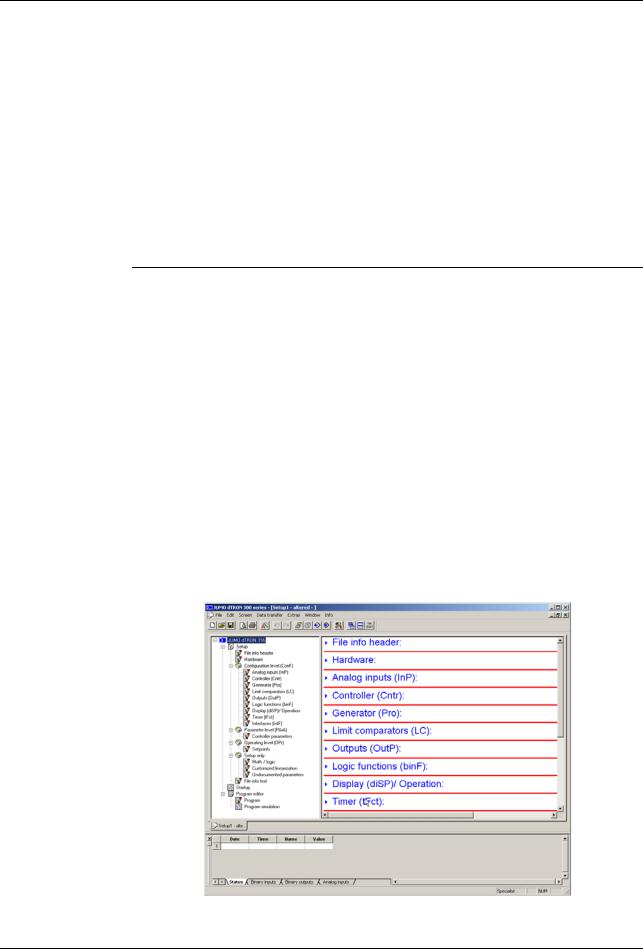

Linearizations for the usual transducers are stored, and a customer-specific linearization table can be programmed.

A setup program is available for user-friendly configuration from a PC.

An RS422/485 or a Profibus-DP interface can be used to integrate the instrument into a data network.

The electrical connection is made at the back of the instrument, via screw terminals.

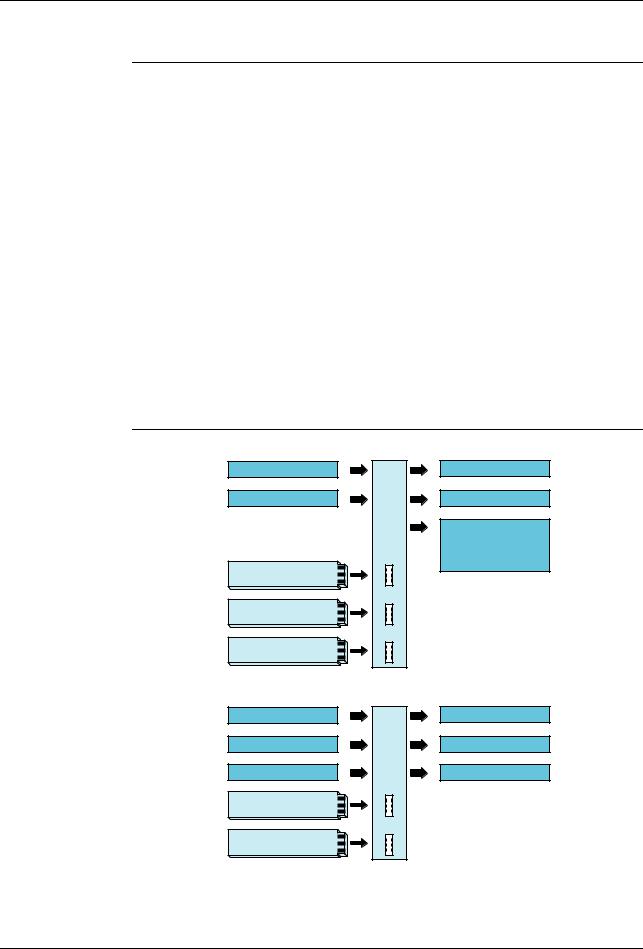

Analog input

2 binary inputs

Option 1

Option 2

Option 3

Type 703042/43/44

2 relays (changeover)

2 logic outputs

Supply voltage 17 V / 20 mA for 2-wire transmitter

|

Type 703041 (48mm x 48mm) |

||

|

Analog input |

2 relays (make) |

|

|

Binary input |

or |

Logic output |

|

Binary input |

or |

Logic output |

|

Option 1 |

||

|

Option 2 |

1. For more detailed explanation, see EN 14597

7

1 Introduction

1.2 Typographical conventions

* Caution

ECaution

|

Note signs |

H Note |

|

v Reference |

This symbol is used when there may be danger to personnel if the instructions are ignored or not followed correctly!

This symbol is used when there may be damage to equipment or data if the instructions are ignored or not followed correctly!

This symbol is used where special care is required when handling components liable to damage through electrostatic discharge.

This symbol is used when your special attention is drawn to a remark.

This symbol refers to further information in other operating instructions, chapters or sections.

HAction This symbol indicates that an action to be performed is instruction described.

The individual steps are marked by this asterisk, e.g. h Press X

|

Representation |

Menu items |

Blinking display

Texts from the setup program are shown in italics, for example: edit program.

|

I |

I I I I I I I I I I I I I I I |

I |

||

|

I |

I |

|||

| <![if ! IE]>

<![endif]>I I I |

<![if ! IE]>

<![endif]>I I I |

|||

|

I |

I |

I |

||

|

I |

I I I I I I I I I I I I I I |

8

2 Identifying the instrument version

2.1 Type designation

Basic type

703041 JUMO dTRON 316, format 48mm x 48mm

incl. 1 analog input, 2 relay outputs and 2 binary inputs or 2 logic outputs

703042 JUMO dTRON 308, format 48mm x 96mm (portrait format) incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

703043 JUMO dTRON 308, format 96mm x 48mm (landscape format) incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

703044 JUMO dTRON 304, format 96mm x 96mm

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

Basic type extensions

8standard, with factory settings

9programming to customer specification

logic outputs (2 are available as standard)

10 / 12V

20 / 18V

|

Type 703042/43/44 |

Type 703041 (no option 3) |

||||||||||||||||||||||

|

1. |

2. |

3. |

Option slot |

Max. number |

Max. number |

Option 1 |

Option 2 |

||||||||||||||||

|

0 |

0 |

0 |

not used |

X |

X |

||||||||||||||||||

|

1 |

1 |

1 |

analog input 2 (universal) |

1 |

1 |

X |

X |

||||||||||||||||

|

2 |

2 |

2 |

relay (changeover) |

2 |

1 |

X |

— |

||||||||||||||||

|

3 |

3 |

3 |

2 relays (make contact) |

2 |

1 |

X |

— |

||||||||||||||||

|

4 |

4 |

4 |

analog output |

2 |

2 |

X |

X |

||||||||||||||||

|

5 |

5 |

5 |

2 binary inputs |

2 |

1 |

X |

X |

||||||||||||||||

|

6 |

6 |

6 |

solid-state relay 1A |

2 |

2 |

X |

X |

||||||||||||||||

|

7 |

7 |

7 |

RS422/485 interface |

1 |

1 |

X |

X |

||||||||||||||||

|

8 |

8 |

8 |

Profibus-DP interface |

1 |

1 |

X |

X |

||||||||||||||||

|

X = available in this option slot, — = not available in this option slot |

|||||||||||||||||||||||

|

Supply |

|||||||||||||||||||||||

|

2 |

3 |

110 — 240V AC -15/+10%, 48 — 63Hz |

|||||||||||||||||||||

|

2 |

5 |

20 — 30V AC/DC, 48 — 63Hz |

|||||||||||||||||||||

|

Extra codes |

|||||||||||||||||||||||

|

0 |

0 |

0 |

none |

||||||||||||||||||||

|

2 |

1 |

4 |

math and logic module |

||||||||||||||||||||

|

2 |

1 |

7 |

ratio controller (requirement: 2 analog inputs) |

||||||||||||||||||||

|

2 |

1 |

8 |

difference controller (requirement: 2 analog inputs) |

||||||||||||||||||||

|

2 |

1 |

9 |

humidity controller (requirement: 2 analog inputs) |

||||||||||||||||||||

|

Approvals |

|||||||||||||||||||||||

|

0 |

0 |

0 |

none |

||||||||||||||||||||

|

0 |

5 |

6 |

DIN EN 14597 |

||||||||||||||||||||

|

dTRON 304 with GL approval |

on request |

||||||||||||||||||||||

|

/ |

1 |

– |

– |

/ |

, |

|||||

|

703041 |

/ |

1 |

8 1 |

– |

1 4 0 – |

2 3 |

/ |

0 0 0 |

, |

9

2 Identifying the instrument version

2.2Scope of delivery

—1 controller

—1 seal

—mounting brackets

—Operating Manual B70.3041.0 in DIN A6 format

1 CD with demo software and PDF documents in DIN A4 format (operating manual and further documentation) can be ordered separately.

The individual documents and programs are available for dowload from www.jumo.net (the software can be enabled for a charge.)

2.3 Accessories

|

PC interface |

PC interface with TTL/RS232 converter and adapter (socket connector) for setup |

|

program |

|

|

Sales No. 70/00350260 |

|

|

USB interface |

|

|

PC interface with USB/TTL converter, adapter (socket conector) and adapter (pins) |

|

|

Sales No. 70/00456352 |

|

|

Setup |

|

|

Setup program with program editor and Startup |

|

|

program |

Sales No. 70/00445443 |

|

Hardware requirements: |

|

|

— PC Pentium 100 or compatible |

|

|

— 128 MB RAM, 30 MB free fixed disc memory |

|

|

— CD ROM drive |

|

|

— free serial or USB interface |

|

|

Software requirements: |

|

|

Microsoft1 Windows 98/NT4.0/ME/2000/XP |

1. Microsoft is a registered trademark of Microsoft Corporation

10

3 Mounting

3.1 Mounting site and climatic conditions

The conditions on the mounting site must meet the requirements specified in the technical data. The ambient temperature on the mounting site can be from 0 to 55 °C, with a relative humidity of not more than 90 %.

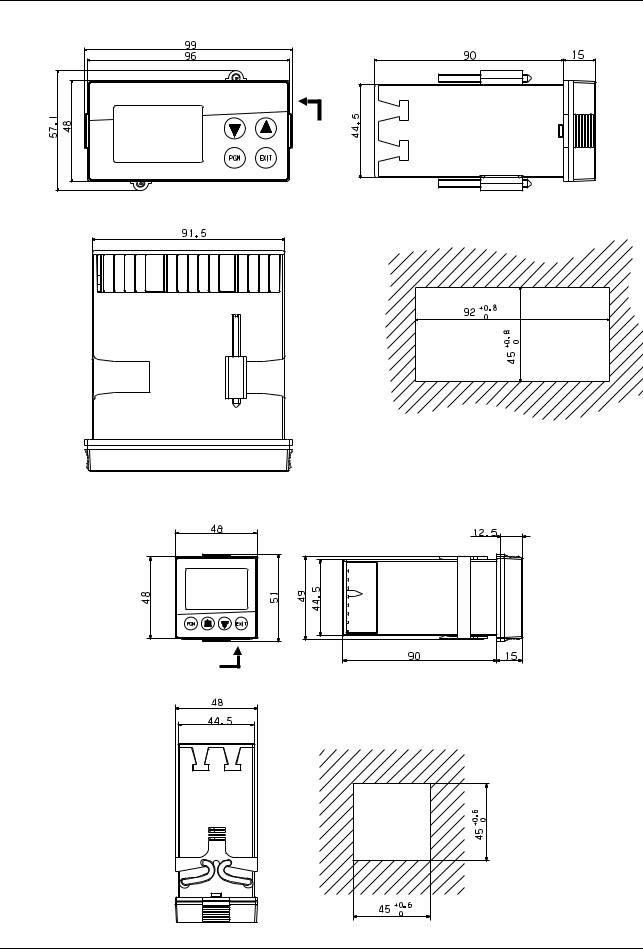

3.2 Dimensions

3.2.1 Type 703044

Setup plug

Panel cut-out

11

3 Mounting

3.2.2 Type 703042/43

<![if ! IE]>

<![endif]>Setup plug

Panel cut-out

3.2.3 Type 703041

Setup plug

Panel cut-out

12

3 Mounting

3.3 Side-by-side mounting

|

Minimum spacing of panel cut-outs |

|||||

|

Type |

horizontal |

vertical |

|||

|

without setup plug: |

|||||

|

703041 |

(48mm x 48mm) |

11mm |

30mm |

||

|

703042 |

(portrait format: 48mm x 96mm)) |

11mm |

30mm |

||

|

703043 |

(landscape format: 96mm x 48mm) |

30mm |

11mm |

||

|

703044 |

(96mm x 96mm) |

11mm |

30mm |

||

|

with setup plug (see arrow): |

|||||

|

703041 |

(48mm x 48mm) |

11mm |

65mm |

||

|

703042 |

(portrait format: 48mm x 96mm)) |

11mm |

65mm |

||

|

703043 |

(landscape format: 96mm x 48mm) |

65mm |

11mm |

||

|

703044 |

(96mm x 96mm) |

11mm |

65mm |

||

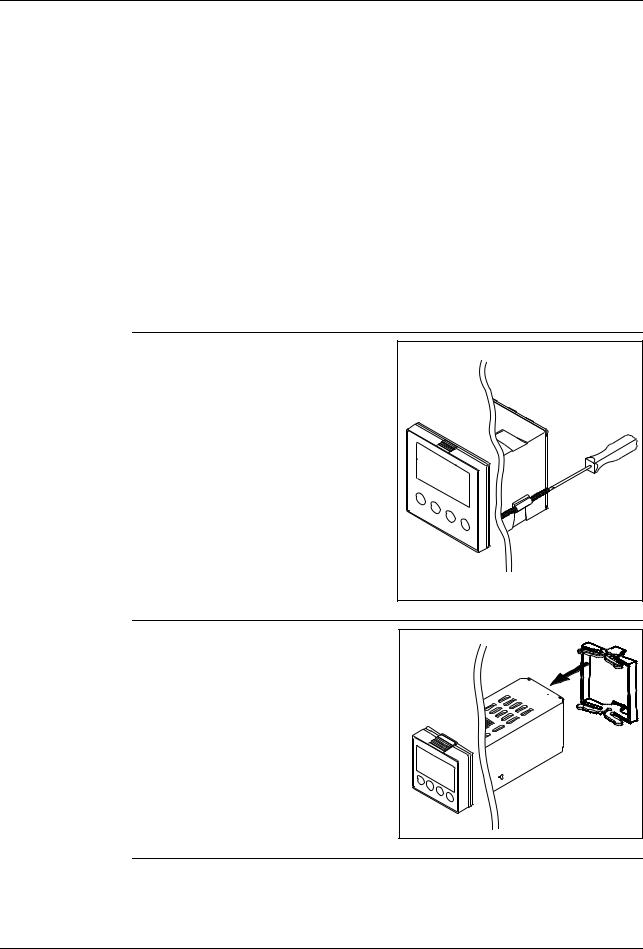

3.4 Fitting in position

Type 703042/43/44 h Fit the seal that is supplied onto the instrument body.

hInsert the controller from the front into the panel cut-out.

hFrom behind the panel, slide the mounting brackets into the guides on the sides of the housing.

The flat faces of the mounting brackets must lie against the housing.

hPush the mounting brackets up to the back of the panel, and tighten them evenly with a screwdriver.

|

Type 703041 |

h Fit the seal that is supplied onto the |

|

instrument body. |

|

|

h Insert the controller from the front into |

|

|

the panel cut-out. |

|

|

h From the back of the panel, push the |

|

|

mounting frame onto the instrument |

|

|

body and press it against the back of |

|

|

the panel, compressing the springs, |

|

|

until the latches snap into the notches |

|

|

provided and it is firmly fixed in position. |

Care of the front The front panel can be cleaned with normal commercial washing, rinsing and cleaning panel agents. It has a limited resistance to organic solvents (e.g. methylated spirits, white

spirit, P1, xylol etc.). Do not use high-pressure cleaning equipment.

13

3 Mounting

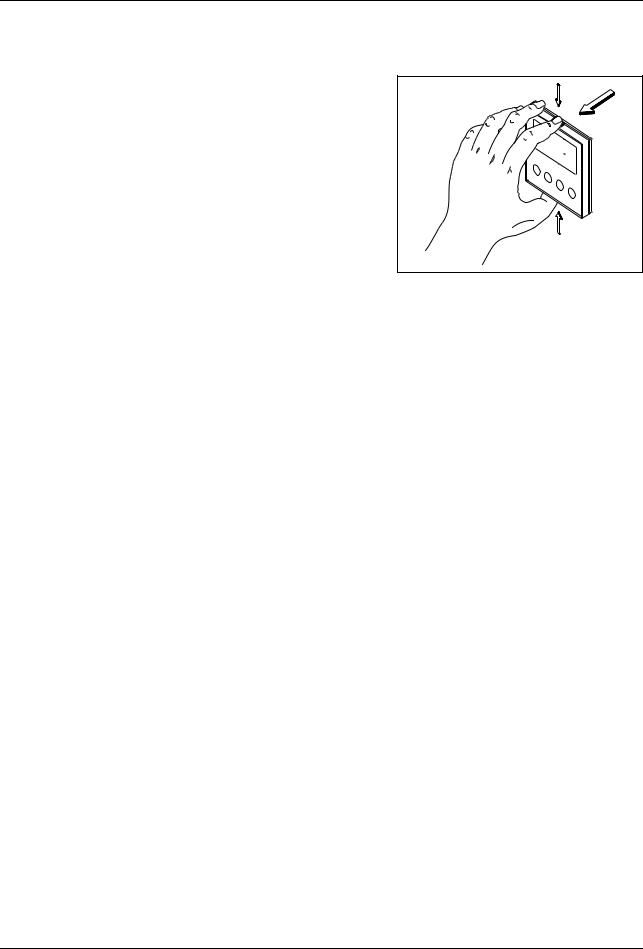

3.5 Removing the controller module

The controller module can be removed from its housing for servicing.

hPress together the knurled areas (top and bottom, or left and right for landscape format) and pull out the

controller module.

HWhen inserting the controller module, make sure that the latches (below the knurled areas) snap into place.

14

4 Electrical connection

4.1Installation notes

—The choice of cable, the installation and the electrical connection must conform to the requirements of VDE 0100 “Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V” or the appropriate local regulations.

—The electrical connection must only be carried out by qualified personnel.

—The instrument shall be operated by mains protected with a branch circuitry overcurrent protection device not more than 20 Amps.

For servicing/repairing a Disconnecting Device shall be provided to disconnect all conductors.

—The load circuit must be fused for the maximum relay current, in order to prevent the output relay contacts becoming welded in the event of a short circuit.

—Electromagnetic compatibility conforms to the standards and regulations cited in the technical data.

—Run input, output and supply cables separately and not parallel to one another.

—Sensor and interface cables should be shielded cables with twisted conductors. Do not run them close to current-carrying components or cables. Ground the shielding on one side.

—Do not connect any additional loads to the supply terminals of the instrument.

—The instrument is not suitable for use in areas with an explosion hazard (Ex areas).

—In addition to faulty installation, incorrect settings on the controller (setpoint, data of the parameter and configuration levels, internal alterations) can also interfere with the correct operation of dependent processes, or even cause damage. Safety devices should always be provided that are independent of the controller (such as overpressure valves or temperature limiters/monitors) and only capable of adjustment by specialist personnel. Please observe the relevant safety regulations for such matters. Since adaptation (self-optimization) can not be expected to handle all possible control loops, an unstable parameterization is theoretically possible. The stability of the actual value that is produced should therefore be checked.

The electrical connection must only be carried out by specialist personnel.

The instrument version can be identified by the type code.

Conductor cross-sections and core-end ferrules for installation

|

Minimum |

Maximum |

Min. length of |

|

|

cross-section |

cross-section |

core-end ferrule |

|

|

Without core-end ferrule |

0.34mm2 |

2.5mm2 |

10mm |

|

(stripped) |

|||

|

Core-end ferrule, no lip |

0.25mm2 |

2.5mm2 |

10mm |

|

Core-end ferrule, lip up to 1.5mm2 |

0.25mm2 |

1.5mm2 |

10mm |

|

Core-end ferrule, lip above 1.5mm2 |

1.5mm2 |

2.5mm2 |

12mm |

|

Twin ferrule with lip |

0.25mm2 |

1.5mm2 |

12mm |

15

4 Electrical connection

4.2 Electrical isolation

3800 V AC

Input 1

Input 2

Binary inputs

Setup interface

RS422/485 PROFIBUS-DP

| <![if ! IE]>

<![endif]>» |

Relay outputs |

|||||||||||||||

|

30 V AC |

||||||||||||||||

|

50 V DC 3800 V AC |

||||||||||||||||

| <![if ! IE]>

<![endif]>» » |

Solid-state relay outputs |

|||||||||||||||

|

30 V AC |

||||||||||||||||

|

50 V DC |

||||||||||||||||

| <![if ! IE]>

<![endif]>» |

Analog outputs |

|||||||||||||||

30 V AC

50 V DC

| <![if ! IE]>

<![endif]>» |

Supply voltage for |

||

|

2-wire transmitter |

30 V AC

50 V DC »

» 3800 V AC

Supply voltage

16

1

1

2

3

4

5

6

7

8

<![if ! IE]>

<![endif]>17

3

L1(L+)

N(L-)

3

4

5

6

7

8

Supply and outputs — terminal strip 3

| <![if ! IE]>

<![endif]>Supply |

L1 |

N |

L- |

|||

|

L1 |

L+ |

|||||

|

L+ |

||||||

|

110—240V AC |

20—30V AC/DC |

|||||

|

N |

||||||

|

L- |

|

3 |

||

|

4 |

P |

|

|

5 |

230V/3A Binary output 1 (Out1) |

|

| <![if ! IE]>

<![endif]>Relays |

S |

|

|

6 |

||

|

7 |

P |

|

|

8 |

230V/3A Binary output 2 (Out2) |

|

|

S |

| <![if ! IE]>

<![endif]>.3.4 |

<![if ! IE]>

<![endif]>3.4 |

| <![if ! IE]>

<![endif]>703041 Type 1 |

<![if ! IE]>

<![endif]>Connection |

| <![if ! IE]>

<![endif]>diagrams |

Outputs — terminal strip 2

1

2

3

4

| <![if ! IE]>

<![endif]>Logic |

||||||

|

6 |

Out3 (+) |

Binary output 3 |

||||

|

7 |

Out4 (+) |

Binary output 4 |

||||

|

8 |

GND (-) |

|||||

Logic output level 12V or 18V (see type code)

As an alternative to binary inputs 1 and 2 (configurable)!

<![if ! IE]>

<![endif]>connection Electrical 4

|

Type 703041 continued |

||||||

|

Outputs and interfaces — terminal strip 1 (option board) |

||||||

|

Analog |

Relay |

2 relays |

Solid-state |

PROFIBUS |

RS422 |

RS485 |

|

output |

(changeover) |

(n.o. make) |

relay |

<![if ! IE]>

<![endif]>Option 2 Option 1

+

Ux / Ix

—

Analog output 5 (Out5)

|

Out8 |

|

|

Binary output 5+8 |

Binary output 5 |

|

(Out5+Out8) |

(Out5) |

|

+ |

(not possible!) |

(not possible!) |

||

|

Ux / Ix |

||||

|

— |

||||

|

Analog output 6 |

Binary output 6 |

|||

|

(Out6) |

(Out6) |

|

VP (+5 V) |

RxD + |

|||

|

RxD/TxD-P (B) |

RxD — |

|||

|

RxD/TxD-N (A) |

TxD + |

RxD/TxD + |

||

|

DGND |

TxD — |

RxD/TxD — |

||

|

VP (+5 V) |

RxD + |

|||

|

RxD/TxD-P (B) |

RxD — |

|||

|

RxD/TxD-N (A) |

TxD + |

RxD/TxD + |

||

|

DGND |

TxD — |

RxD/TxD — |

||

H Note numbering of outputs.

v Chapter 8.5 “Outputs “OutP””

<![if ! IE]>

<![endif]>connection Electrical 4

Type 703041 continued

Analog input 1 and binary inputs 1+2 — terminal strip 2

<![if ! IE]>

<![endif]>Analog 1

Resistance thermometer

|

1 |

||

|

2 |

||

|

3 |

||

|

4 |

|

Resistance |

Resistance |

Resistance |

Thermo- |

Current |

Voltage |

Voltage |

|

thermometer |

thermometer |

transmitter |

couple |

0(2)—10V |

0—1V |

|

+ |

|||||||||||||||||

|

E |

+ |

Ux |

+ |

||||||||||||||

|

— |

|||||||||||||||||

|

S |

— |

+ |

Ux |

||||||||||||||

|

— |

|||||||||||||||||

|

A |

Ix— / Ix~ |

||||||||||||||||

|

— |

|||||||||||||||||

| <![if ! IE]>

<![endif]>Logic |

|||||||

|

6 |

bin1 |

Binary input 1 |

As an alternative to binary outputs 3 and 4 |

||||

|

(configurable)! |

|||||||

|

7 |

bin2 |

Binary input 2 |

|||||

|

8 |

GND |

Analog input 2 and binary inputs 3…6 — terminal strip 1 (option boards)

<![if ! IE]>

<![endif]>19

<![if ! IE]>

<![endif]>connection Electrical 4

3

L1(L+)

N(L+)

4

5

6

8

9

11

12

13

15

16

17

Supply and outputs — terminal strip 3

| <![if ! IE]>

<![endif]>Supply |

L1 |

N |

L- |

|||

|

L1 |

L+ |

|||||

|

L+ |

||||||

|

110—240V AC |

20—30V AC/DC |

|||||

|

N |

||||||

|

L- |

|

4 |

|||||||

|

5 |

|||||||

|

6 |

|||||||

| <![if ! IE]>

<![endif]>= |

8 |

+ |

17V/20mA |

Supply for 2-wire transmitter |

|||

| <![if ! IE]>

<![endif]>U |

U= |

(off-load voltage approx. 25V) |

|||||

|

9 |

— |

||||||

|

11 |

Ö |

|||

|

12 |

P |

230V/3A |

Binary output 1 (Out1) |

|

| <![if ! IE]>

<![endif]>Relays |

13 |

S |

||

|

15 |

Ö |

|||

|

16 |

P |

230V/3A |

Binary output 2 (Out2) |

|

|

17 |

S |

Outputs — terminal strip 2

|

6 |

|||||||

| <![if ! IE]>

<![endif]>Logic |

7 |

||||||

|

8 |

Out3 (+) |

Binary output 3 |

Logic output level 12V or 18V |

||||

|

9 |

Out4 (+) |

Binary output 4 |

(see type code) |

||||

|

10 |

GND (-) |

||||||

| <![if ! IE]>

<![endif]>703042/43/44 Type 2.3.4 |

<![if ! IE]>

<![endif]>connection Electrical 4 |

|

Type 703042/43/44 continued |

|||

|

Outputs and interfaces — terminal strip 1 (option boards) |

|||

|

Analog |

Relay |

2 relays |

Solid-state |

|

output |

(changeover) |

(n.o. make) |

relay |

| <![if ! IE]>

<![endif]>1 |

1 |

Ö |

Out5 |

||

|

2 |

+ |

P |

|||

| <![if ! IE]>

<![endif]>Option |

Ux / Ix |

||||

|

3 |

— |

S |

Out8 |

|

4 |

Analog output 5 |

Binary output 5 |

Binary output 5+8 |

Binary output 5 |

|

|

(Out5) |

(Out5) |

(Out5+Out8) |

(Out5) |

||

| <![if ! IE]>

<![endif]>2 |

5 |

Ö |

Out6 |

||

|

6 |

+ |

P |

|||

| <![if ! IE]>

<![endif]>Option |

Ux / Ix |

||||

|

7 |

— |

S |

Out9 |

|

8 |

Analog output 6 |

Binary output 6 |

Binary output 6+9 |

Binary output 6 |

|

|

(Out6) |

(Out6) |

(Out6+Out9) |

(Out6) |

||

| <![if ! IE]>

<![endif]>3 |

9 |

Ö |

Out7 |

||

|

10 |

+ |

P |

|||

| <![if ! IE]>

<![endif]>Option |

Ux / Ix |

||||

|

11 |

— |

S |

Out0 |

|

12 |

Analog output 7 |

Binary output 7 |

Binary output 7+10 |

Binary output 7 |

|

|

(Out7) |

(Out7) |

(Out7+Out0) |

(Out7) |

||

H Note numbering of outputs.

v Chapter 8.5 “Outputs “OutP””

<![if ! IE]>

<![endif]>21

|

PROFIBUS |

RS422 |

RS485 |

||||||

|

VP (+5 V) |

RxD + |

|||||||

|

RxD/TxD-P (B) |

RxD — |

|||||||

|

RxD/TxD-N (A) |

TxD + |

RxD/TxD + |

||||||

|

DGND |

TxD — |

RxD/TxD — |

||||||

|

VP (+5 V) |

RxD + |

|||||||

|

RxD/TxD-P (B) |

RxD — |

|||||||

|

RxD/TxD-N (A) |

TxD + |

RxD/TxD + |

||||||

|

DGND |

TxD — |

RxD/TxD — |

||||||

|

VP (+5 V) |

RxD + |

|||||||

|

RxD/TxD-P (B) |

RxD — |

|||||||

|

RxD/TxD-N (A) |

TxD + |

RxD/TxD + |

||||||

|

DGND |

TxD — |

RxD/TxD — |

||||||

<![if ! IE]>

<![endif]>connection Electrical 4

Type 703042/43/44 continued

Analog input 1 and binary inputs 1+2 — terminal strip 2

<![if ! IE]>

<![endif]>connection Electrical 4

Type 703042/43/44 continued

Analog input 2 and binary inputs 3…8 — terminal strip 1 (option boards)

<![if ! IE]>

<![endif]>23

<![if ! IE]>

<![endif]>connection Electrical 4

4 Electrical connection

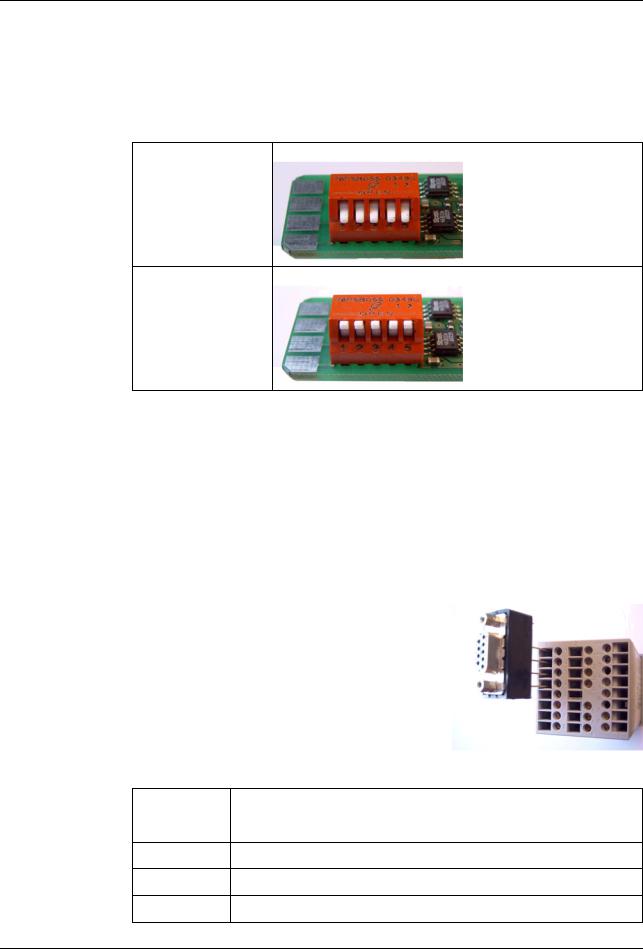

4.3.3 Termination resistor for the RS422/485 serial interface

For fault-free operation of several devices in a line structure, their internal termination resistors must be activated at the start and end.

h Pull plug-in module out towards the front by pressing on the knurled areas

h Using a ballpoint pen, press all the white switches into the same direction

|

Bus termination |

h Push all 5 switches down |

|

resistor active: |

|

No bus termination |

h Push all 5 switches up |

|

(ex-factory) |

|

h Re-insert the module back into the housing |

|

|

Check |

h Press the P+ Ikeys |

|

To the right of the green “VErS” display, “ON” is shown for active and “OFF“ for inac- |

|

|

tive termination resistors. |

4.3.4 Connection of the PROFIBUS-DP connector

|

Mounting the |

h Identify option slot with the PROFIBUS-DP interface by means of the |

|

adapter |

type code (in the case of pre-configured devices) |

|

In this example, the PROFIBUS-DP |

|

|

interface is in option slot 1 |

|

|

HTo fit the D-SUB adapter, open the housing |

|

|

of the adapter; otherwise the terminal |

|

|

screws are hided by the adapter. |

Assignment of the 9-pole D-SUB socket

|

Pin: Signal |

Designation |

|

1: VP |

Supply voltage positive |

2:RxD/TxD-P Receive/Transmit data positive

3:RxD/TxD-N Receive/Transmit data negative

4:DGND Ground

24

- До двух программируемых аналоговых входов

- Четыре программируемых заданных значения (уставки), два набора параметров

- Программная функция с 8 сегментами, или функция рампы

- Математический и логический модуль

- 4 предельных компаратора

- Две функции таймера

- Две процедуры самооптимизации

- Быстрая и удобная конфигурация через setup-программу с редактором программы

- RS422/485 — интерфейс

- Profibus-DP интерфейс

- Разрешение cUL/UL

Описание

Серия регуляторов JUMO dTRON 300 включает в себя четыре свободно программируемых прибора с различными форматами по DIN для регулирования температуры, давления и других переменных процесса. Жидкокристаллический высококонтрастный многоцветный экран для отображения действительного и заданного значений, а также комментариев оператора, содержит два четырехразрядных 7-сегментных дисплея, два одноразрядных 16-сегментных дисплея, дисплей для отображения текущего заданного значения, шесть индикаторов переключения положения и индикаторы для отображения единицы измерения, функции рампы и режима ручного управления.

Управление прибором осуществляется с помощью четырех кнопок.

Приборы могут работать как 2-позиционные, 3-прозиционные, 3-прозиционные шаговые или непрерывные регуляторы. Программное обеспечение предусматривает наличие программной функцию или функции рампы, переключение набора параметров, два способа автонастройки (самооптимизация), математический и логический модуль, а также 4 предельных компаратора.

Прибор содержит таблицы линеаризации обычных типов датчиков, можно запрограммировать собственную таблицу линеаризации. Для простоты конфигурирования с ПК поставляется Setup-программа. Для интегрирования прибора в сеть можно использовать последовательный интерфейс RS422/485 или Profibus-DP.

Электрические соединения осуществляются с помощью винтовых зажимов на задней панели прибора. Возможные конфигурации входов и выходов показаны на блок-схеме. Платы расширения (опции) универсальны и подходят для всех приборов серии.

- Аналогичные товары

Вся информация на сайте о товарах и ценах носит справочный характер и не является публичной офертой. Производитель оставляет за собой право изменять характеристики товара, его внешний вид и комплектность без предварительного уведомления продавца

|

Серия dTRON доступна в четырех DIN-форматах. Серия состоит из 4 программируемых пользователем устройств для контроля температуры, давления и других переменных процесса. Устройства контролируют и управляют температурой жидких и газообразных сред согласно DIN EN 14597.

|

|||||||||||||||