Introduction

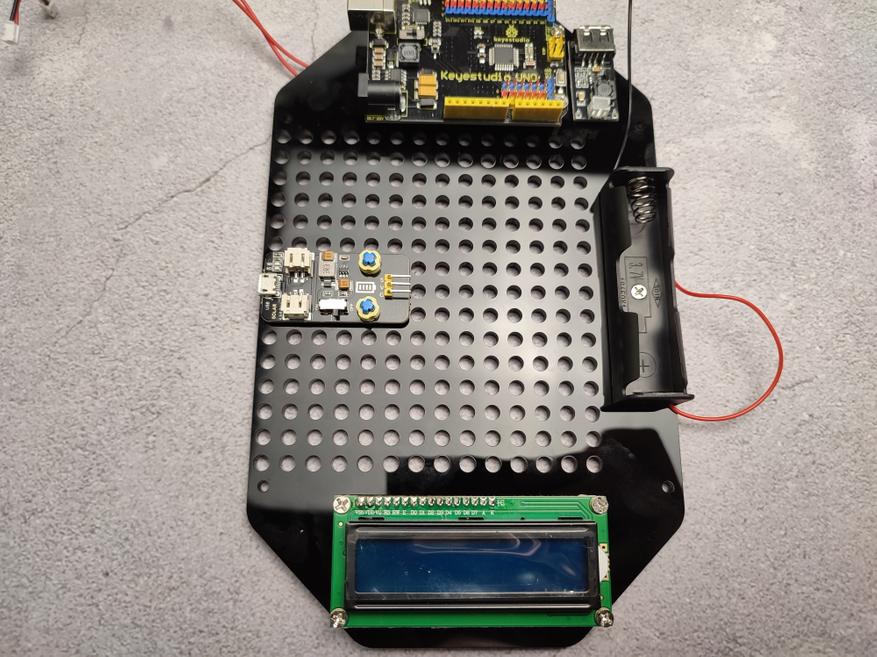

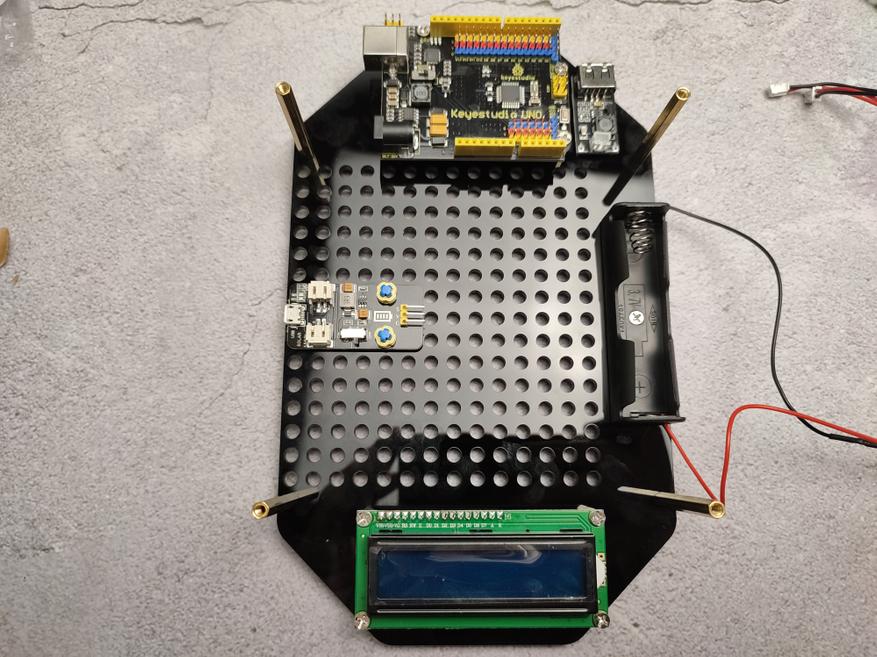

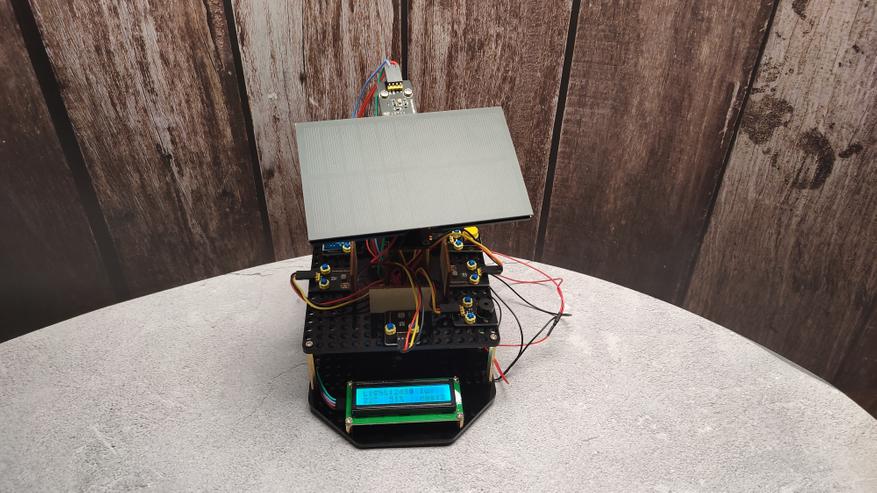

keyestudio super learning kit is suitable for Arduino enthusiasts. This kit includes 32 projects with detailed tutorials, starting from the basics to more complex projects.

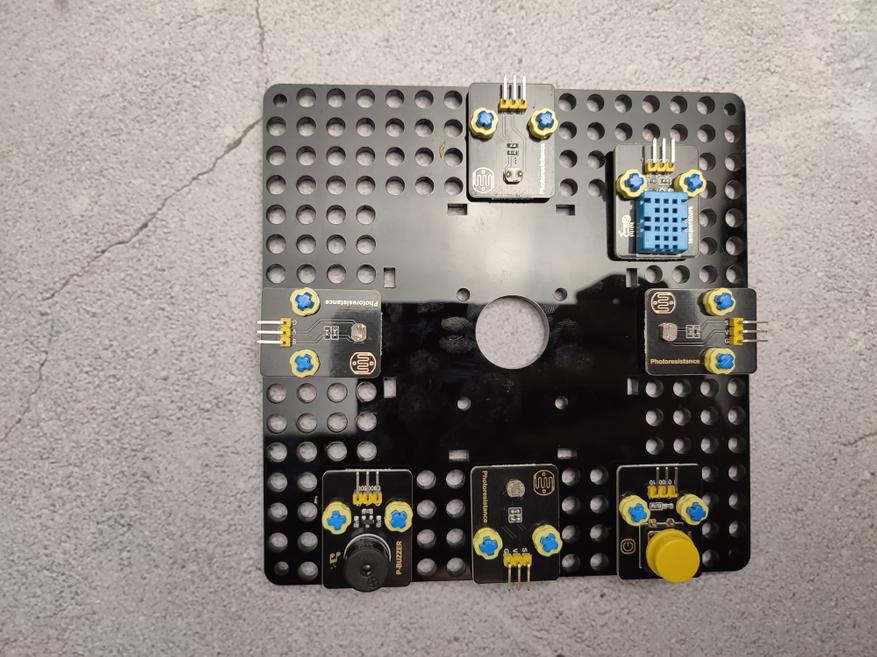

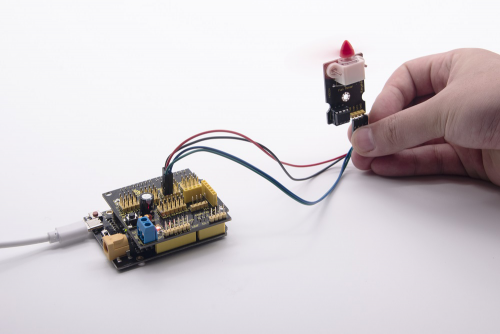

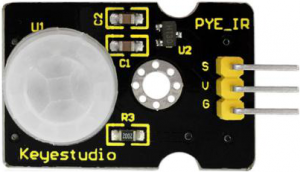

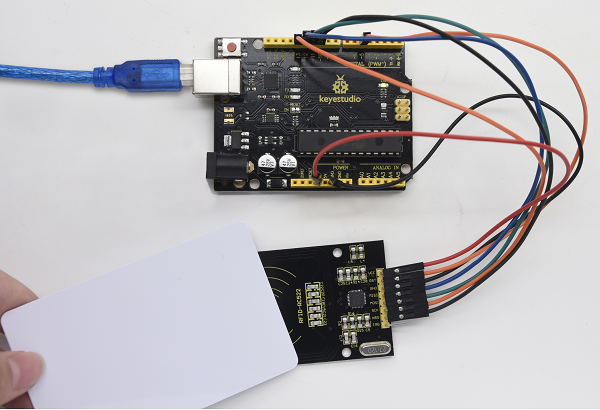

Different from other kits, it adds some functional modules, such as RFID, temperature and humidity module. There is connection diagram and code for each project, making it easy for you to learn.

At the same time, each project has Scratch graphic programming and Arduino C language programming, so that you can access the underlying code.

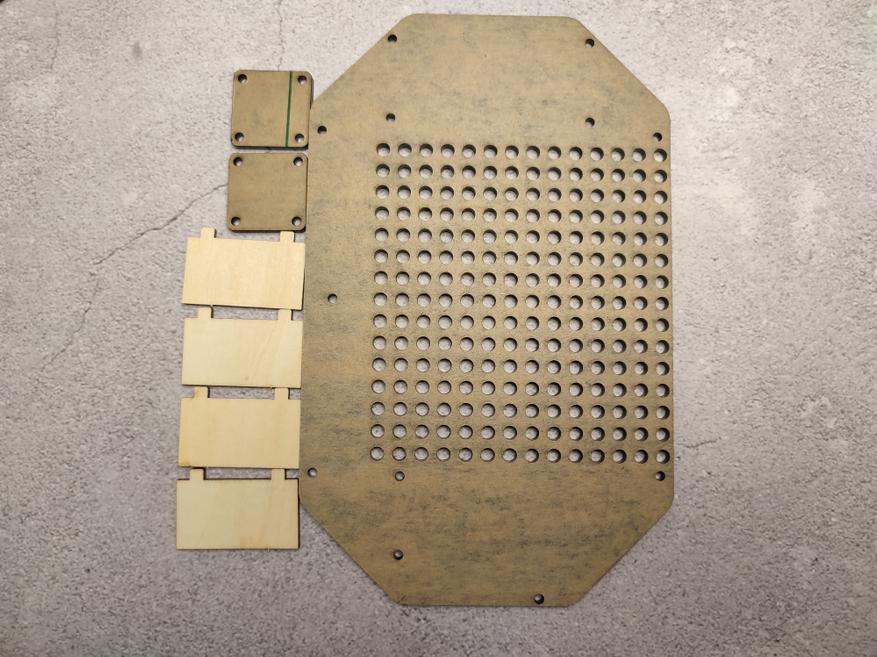

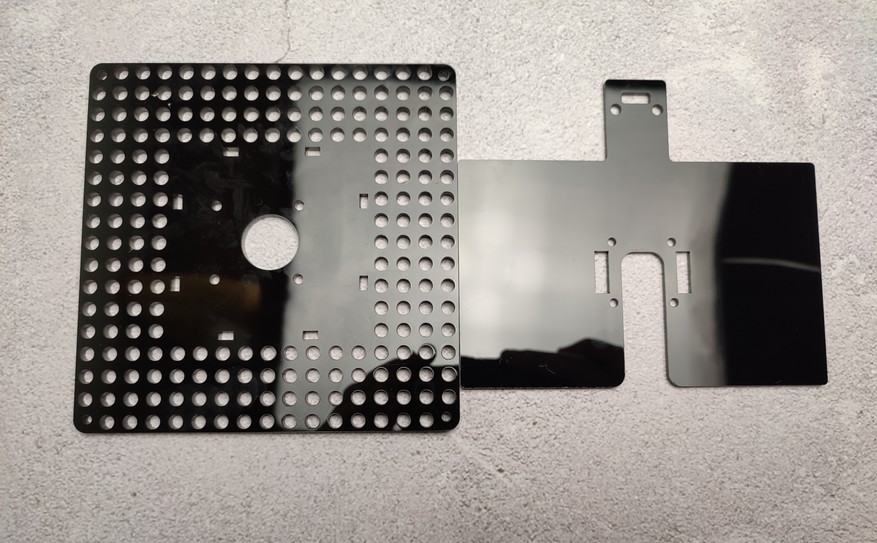

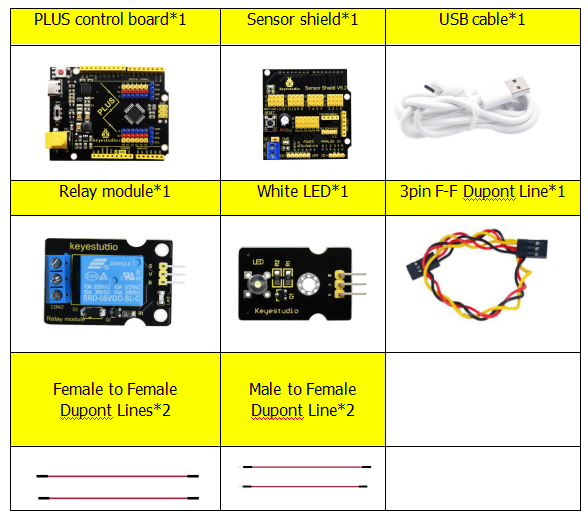

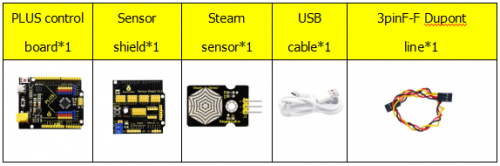

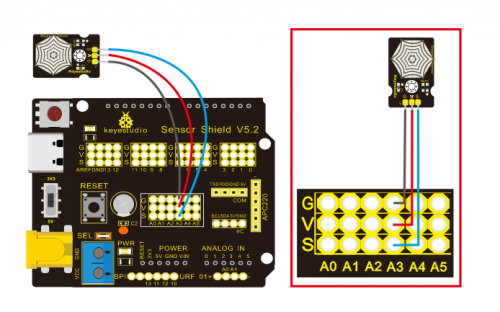

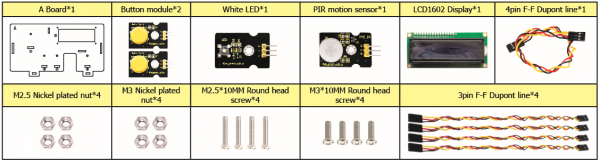

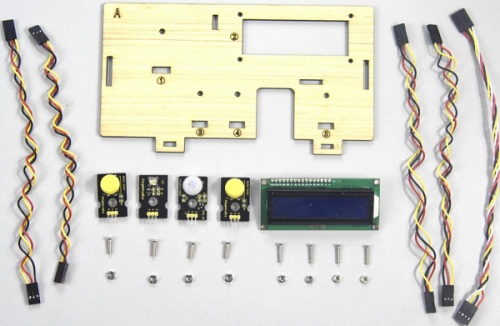

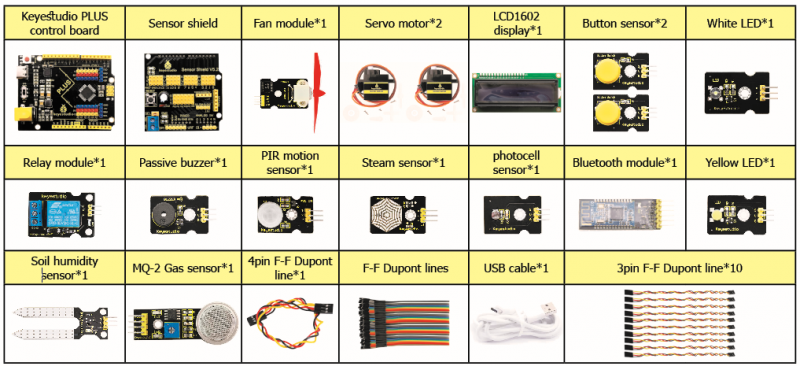

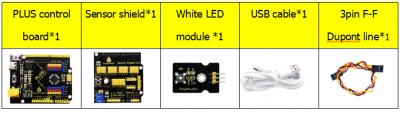

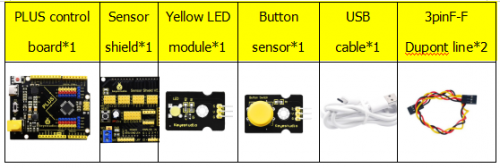

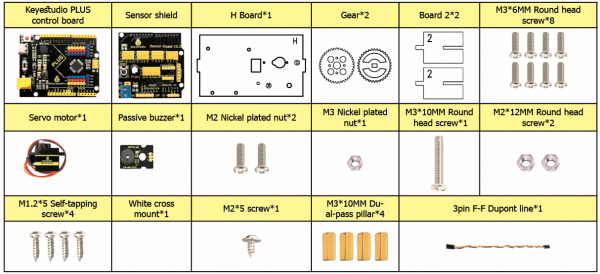

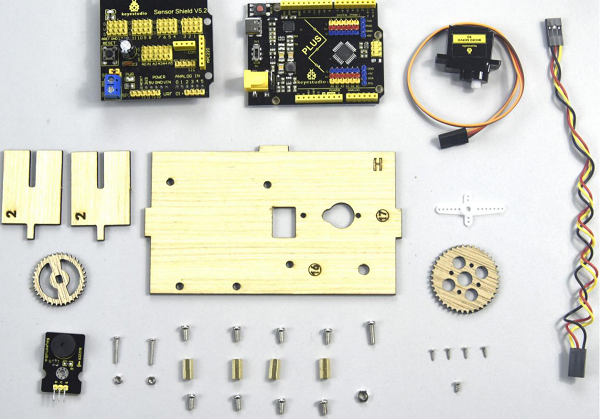

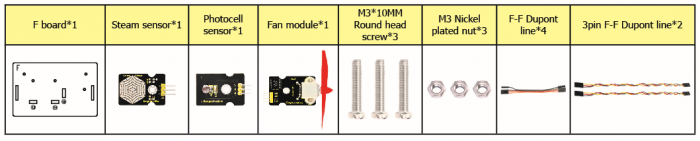

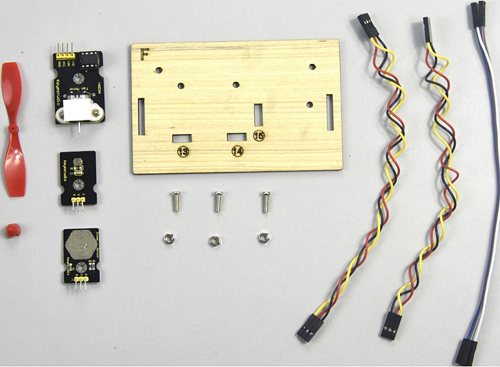

Component List

NOTE: KS0077 Kit doesn’t include a mainboard; KS0078 Kit includes V4.0 board; KS0079 Kit includes MEGA 2560 board:

Install Arduino IDE and Driver

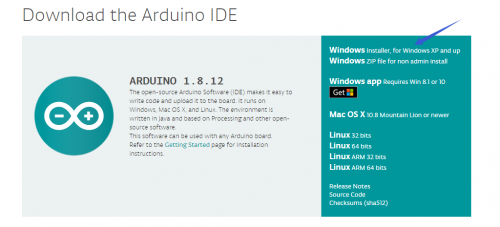

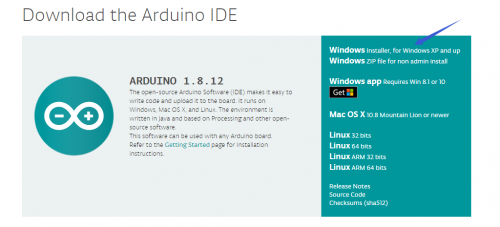

Download software

When we get control board, we need to download Arduino IDE and driver firstly.

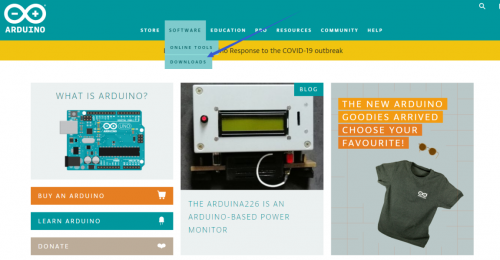

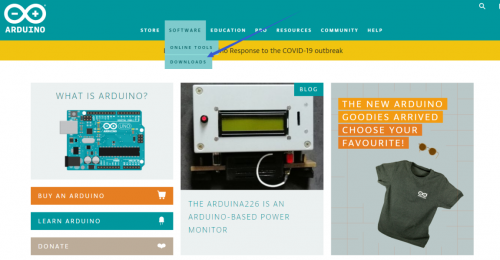

You could download Arduino IDE from the official website:

https://www.arduino.cc/, click the SOFTWARE on the browse bar, click “DOWNLOADS” to enter download page, as shown below:

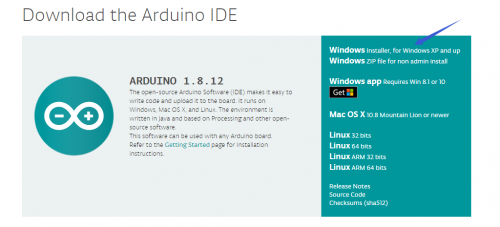

There are various versions for Arduino, just download a suitable version for your system, we will take WINDOWS system as an example to show you how to download and install.

There are two versions for WINDOWS system, one is installed version, another one is download version, you just need to download file to computer directly and unzip it. These two versions can be used normally. Choose one and download on your computer.

You just need to click JUST DOWNLOAD, then click the downloaded file to install it. And when the ZIP file is downloaded, you can directly unzip and start it.

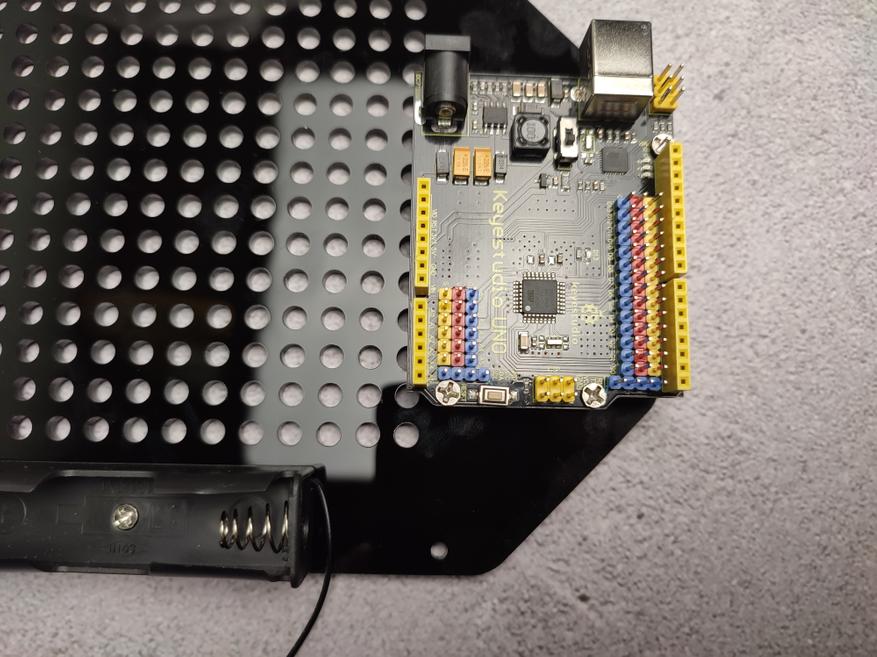

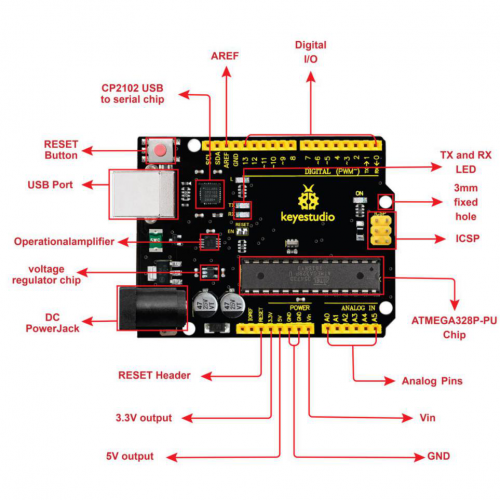

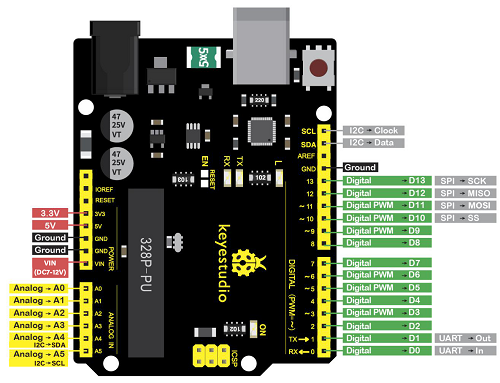

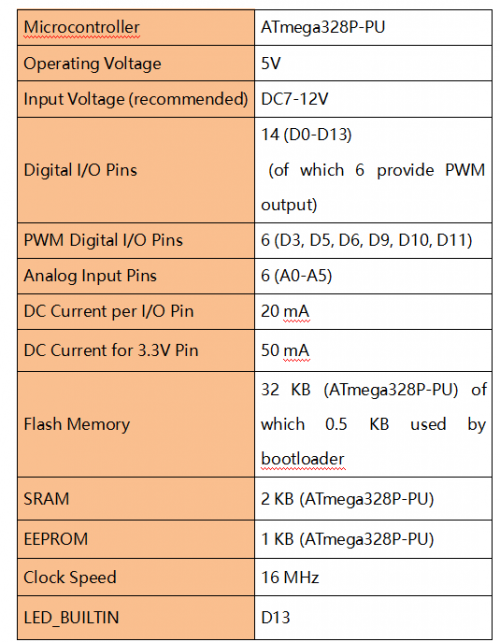

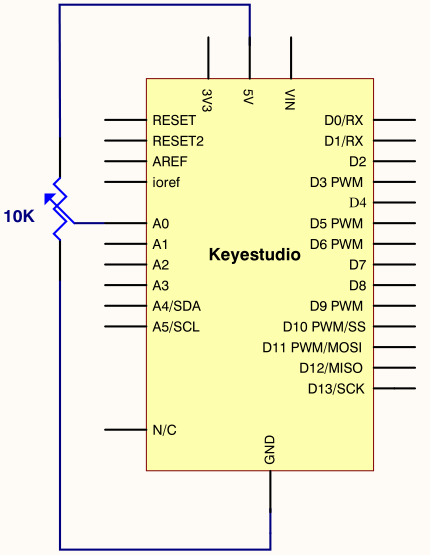

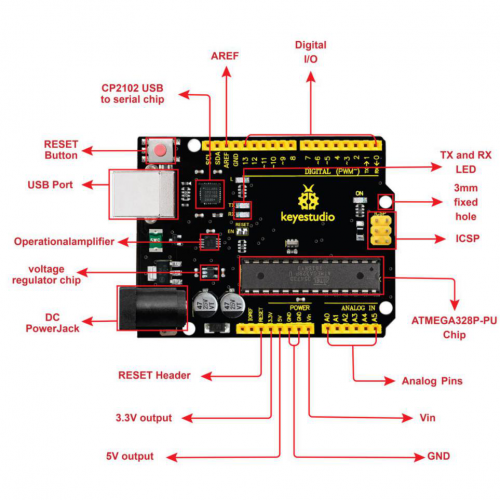

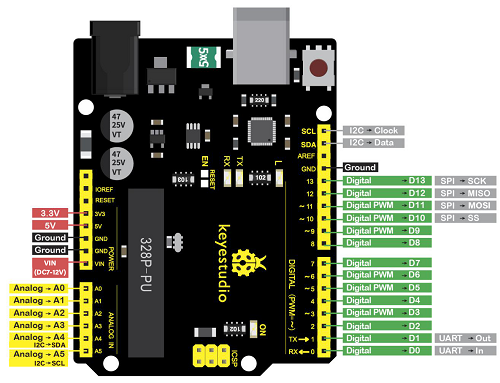

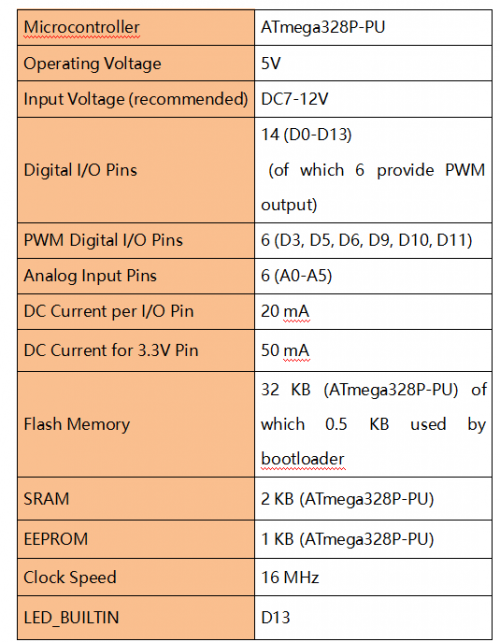

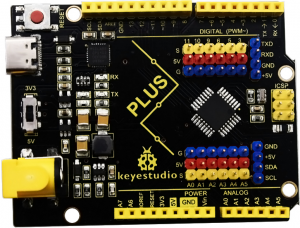

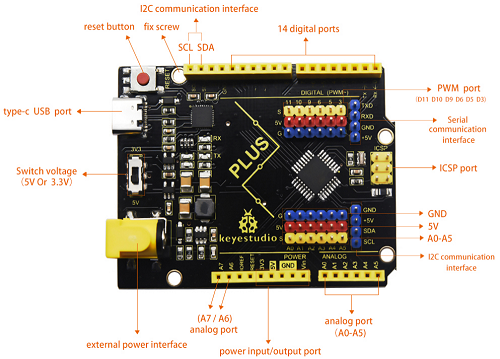

Keyestudio V4.0 Development Board

We need to know keyestudio V4.0 development board, as a core of this smart car.

keyestudio V4.0 development board is an Arduino uno-compatible board, which is based on ATmega328P MCU, and with a cp2102 Chip as a UART-to-USB converter.

It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

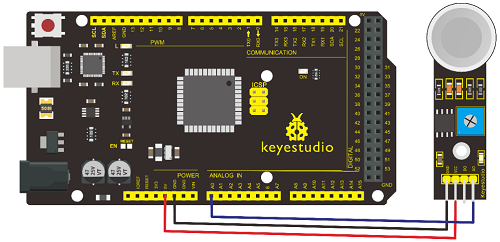

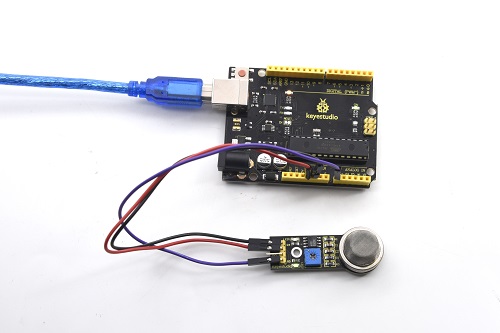

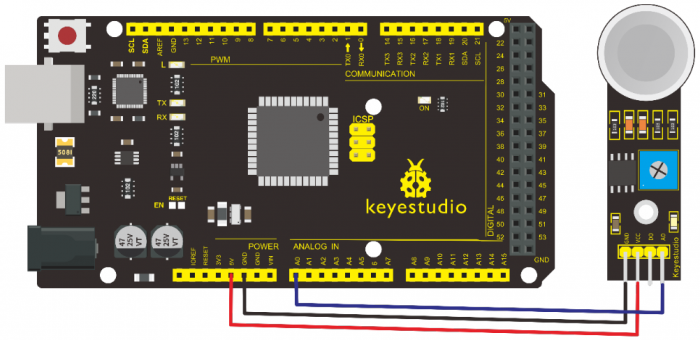

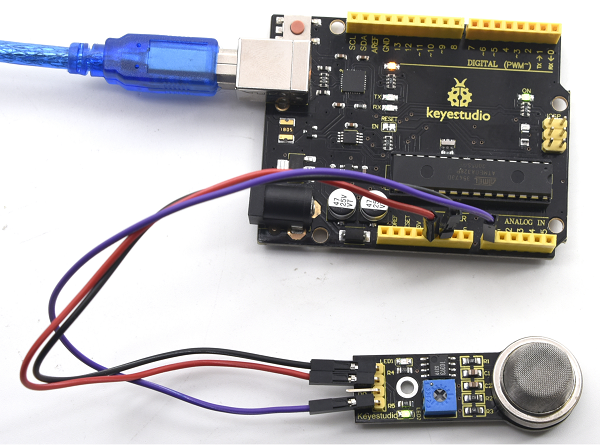

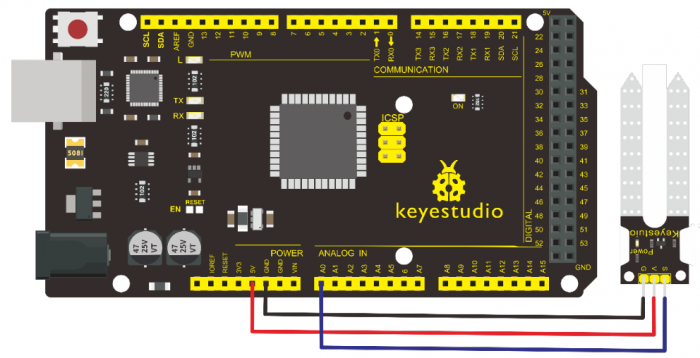

Keyestudio MEGA 2560 Board

Keyestudio Mega 2560 R3 is a microcontroller board based on the ATMEGA2560-16AU , fully compatible with ARDUINO MEGA 2560 R3.

It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, 1 ICSP header, and a reset button. The built-in ICSP port can burn the firmware for ATMEGA2560-16AU directly. This chip is burnt the firmware well before leaving the factory, therefore, we hardly use it. We can power on by USB wire, DC head and Vin GND pins. To facilitate wiring, a 0.5 m USB wire is provided for you.

Specialized Functions of Some Pins:

1. Serial Communication: D0 (RX0) and D1 (TX1); Serial 1: D19 (RX1) and D18 (TX1); Serial 2: D17 (RX2) and D16 (TX2); Serial 3: D15 (RX3) and D14 (TX3). Used to receive (RX) and transmit (TX) TTL serial data. Pins 0 and 1 are also connected to the corresponding pins of the CP2102 USB-to-TTL Serial chip.

2. PWM Pins (Pulse-Width Modulation): D2 to D13, and D44 to D46. Provide 8-bit PWM output with the analogWrite() function.

3. External Interrupts: D2 (interrupt 0), D3 (interrupt 1), D18 (interrupt 5), D19 (interrupt 4), D20 (interrupt 3), and D21 (interrupt 2). These pins can be configured to trigger an interrupt on a low level, a rising or falling edge, or a change in level. See the attachInterrupt() function for details.

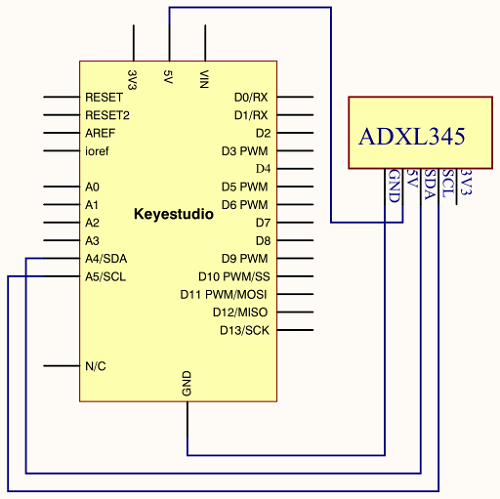

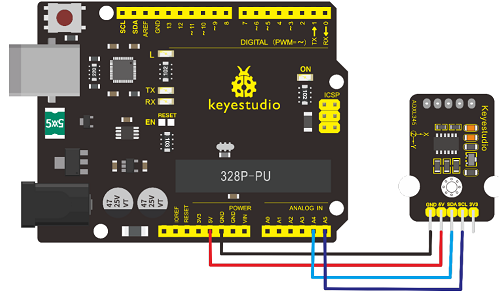

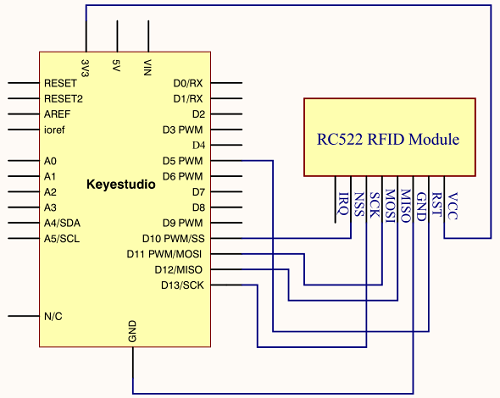

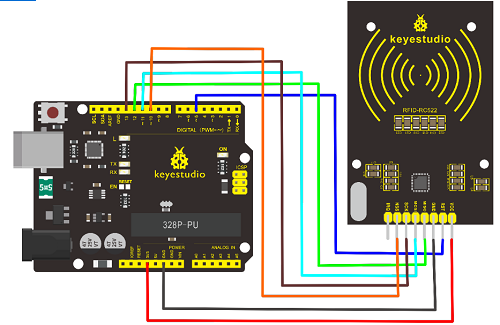

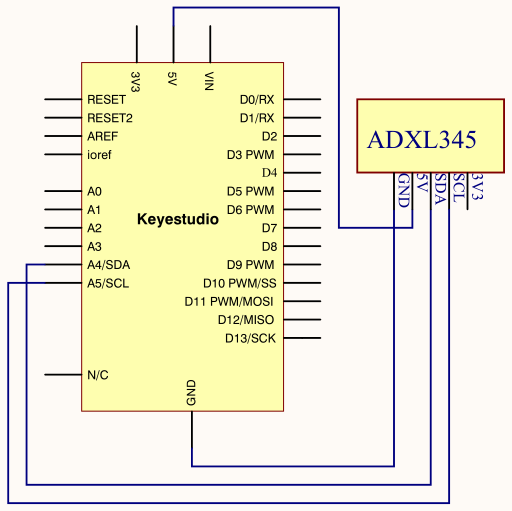

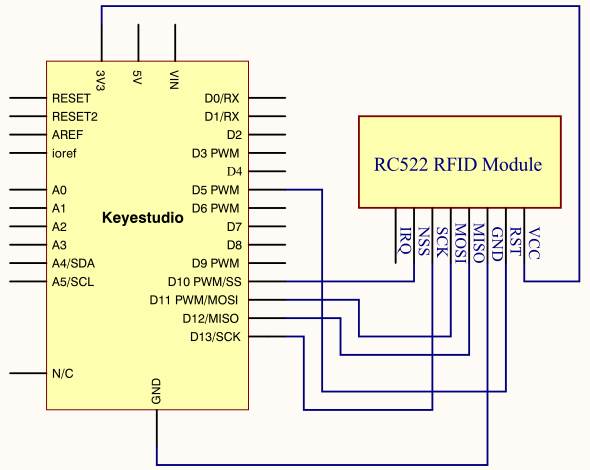

4. SPI communication: D53 (SS), D52 (SCK), D51 (MOSI), D50 (MISO). These pins support SPI communication using theSPI library. The SPI pins are also broken out on the ICSP header, which is physically compatible with the Arduino Uno.

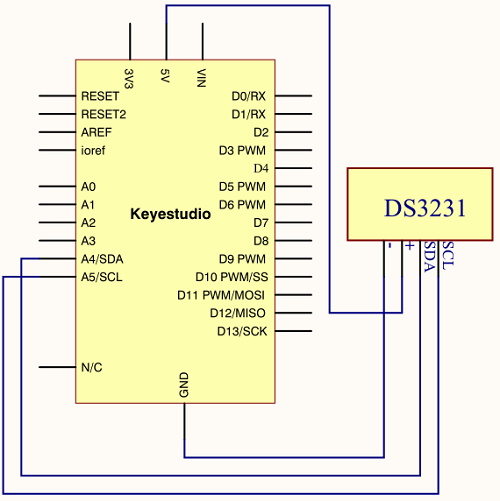

5. IIC communication: D20 (SDA); D21 (SCL). Support TWI communication using the Wire library.

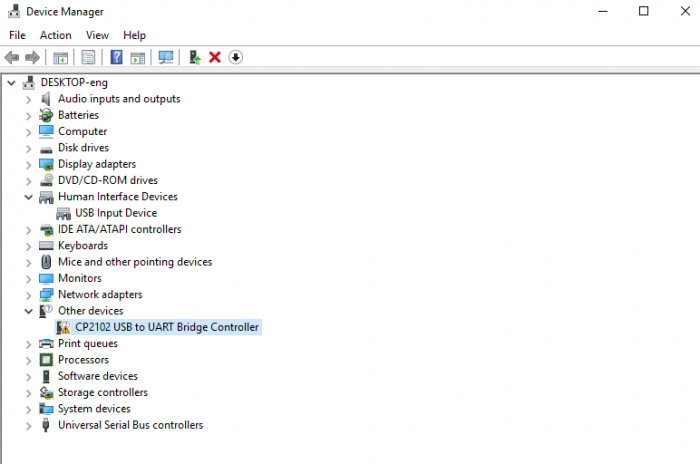

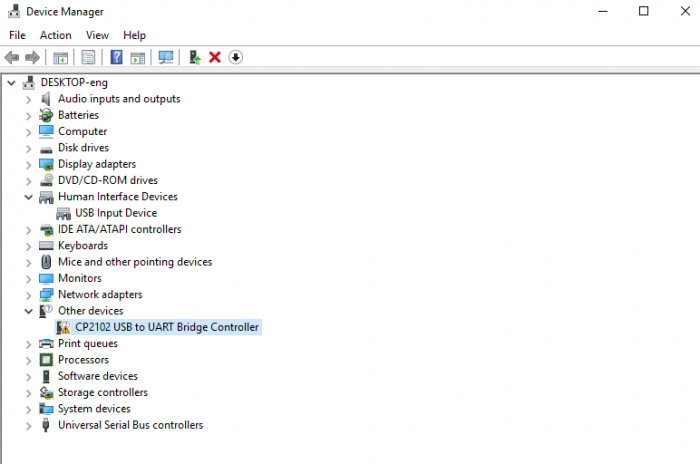

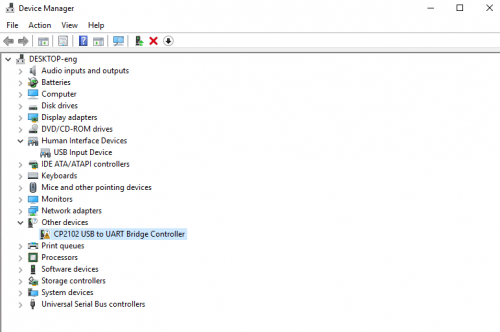

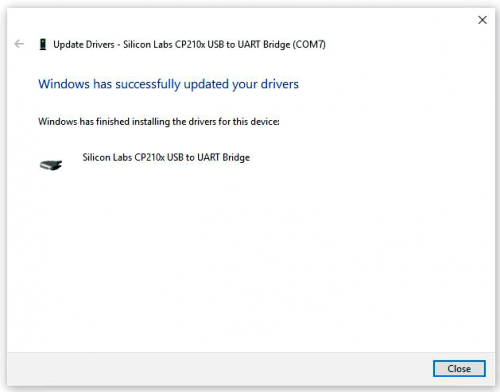

Installing driver

Let’s install the driver of keyestudio PLUS control board. The USB-TTL chip on PLUS board adopts CP2102 serial chip. The driver program of this chip is included in Arduino 1.8 version and above, which is convenient. Plug on USB port of board, the computer can recognize the hardware and automatically install the driver of CP2102.

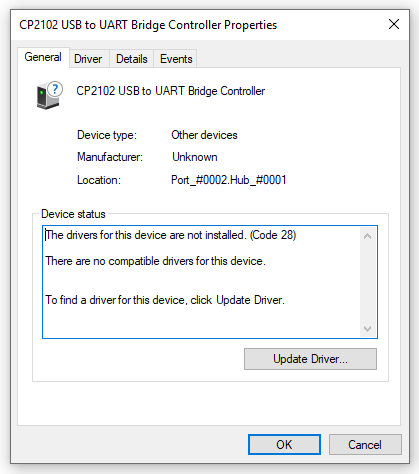

If install unsuccessfully, or you intend to install manually, open the device manager of computer. Right click Computer—— Properties—— Device Manager.

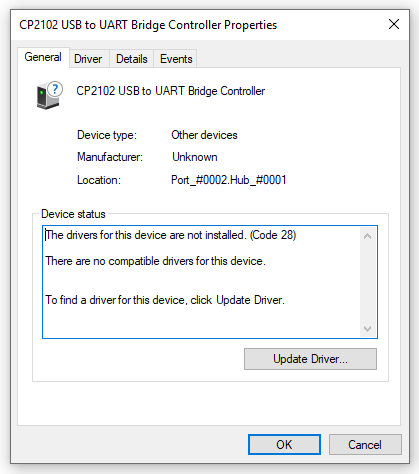

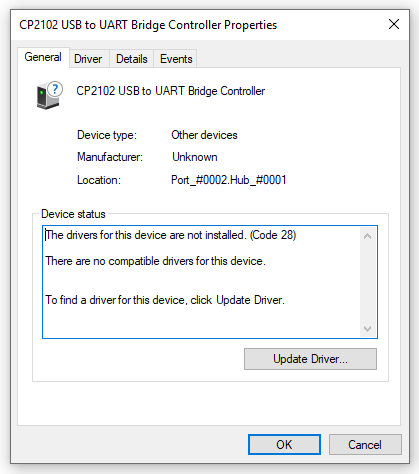

There is a yellow exclamation mark on the page, which implies installing the driver of CP2102 unsuccessfully. Then we double click the hardware and update the driver.

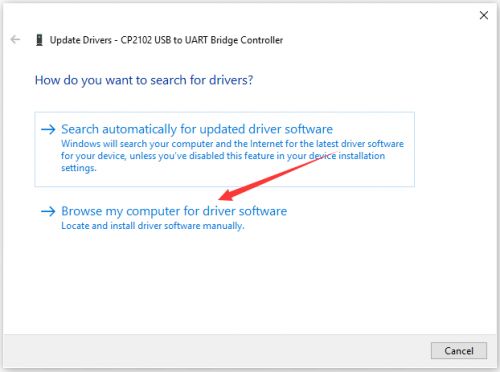

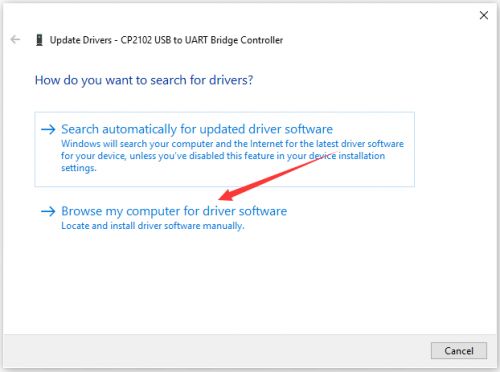

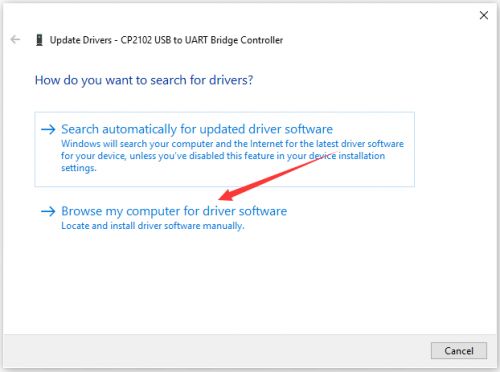

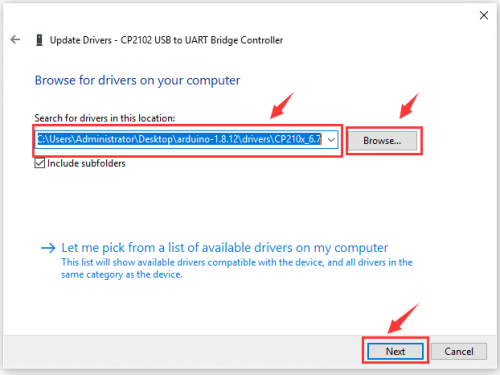

Click “OK” to enter the following page, click “browse my computer for updated driver software”, find out the installed or downloaded ARDUINO software. As shown below:

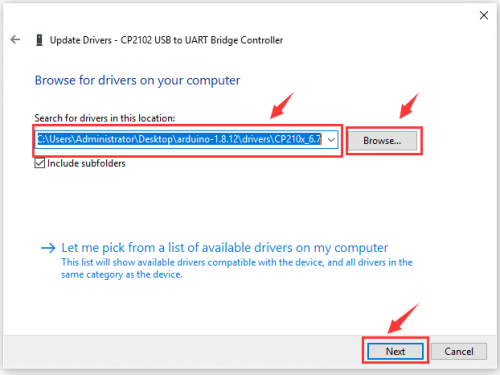

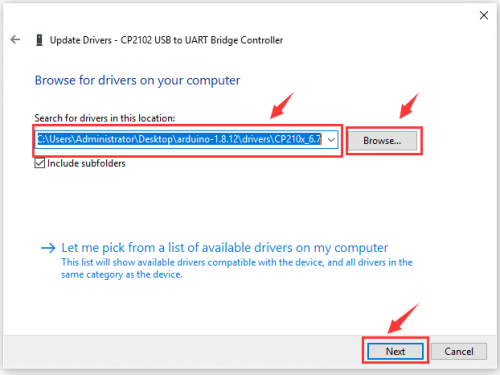

There is a DRIVERS folder in Arduino software installed package(), open driver folder and you can see the driver of CP210X series chips.

We click “Browse”, then find out the driver folder, or you could enter “driver” to search in rectangular box, then click “next”, the driver will be installed successfully. (I place Arduino software folder on the desktop, you could follow my way)

Open device manager, we will find the yellow exclamation mark disappear. The driver of CP2102 is installed successfully.

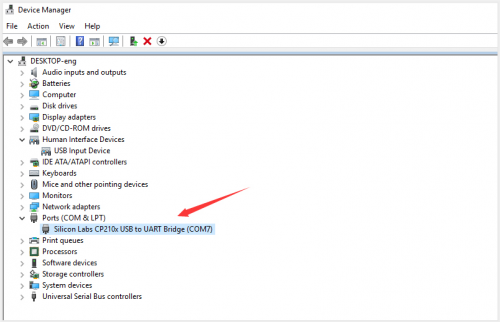

Arduino IDE Setting

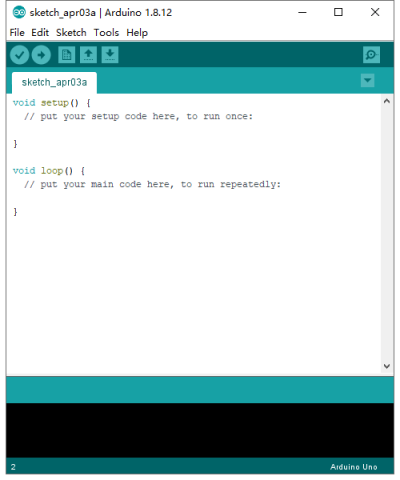

Click

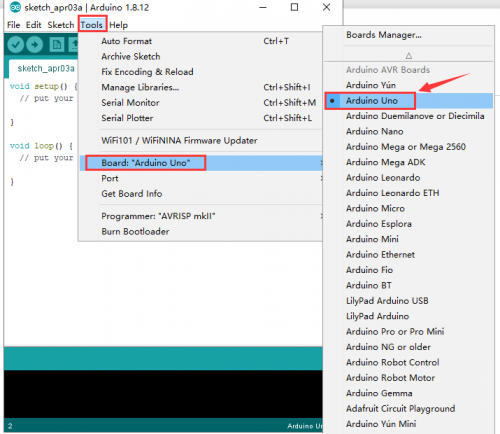

To avoid the errors when uploading the program to the board, you need to select the correct Arduino board that matches the board connected to your computer.

Then come back to the Arduino software, you should click Tools→Board, select the board. (as shown below)

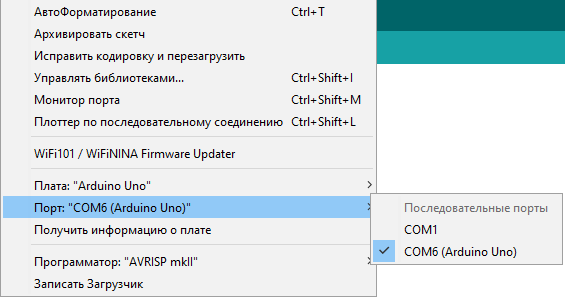

Then select the correct COM port (you can see the corresponding COM port after the driver is successfully installed)

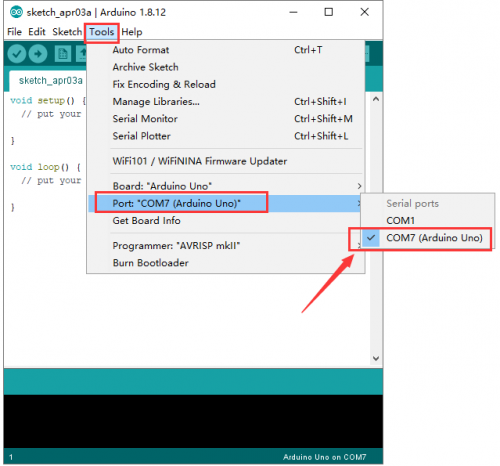

Before uploading the program to the board, let’s demonstrate the function of each symbol in the Arduino IDE toolbar.

A- Used to verify whether there is any compiling mistakes or not.

B- Used to upload the sketch to your Arduino board.

C- Used to create shortcut window of a new sketch.

D- Used to directly open an example sketch.

E- Used to save the sketch.

F- Used to send the serial data received from board to the serial monitor.

Start your first program

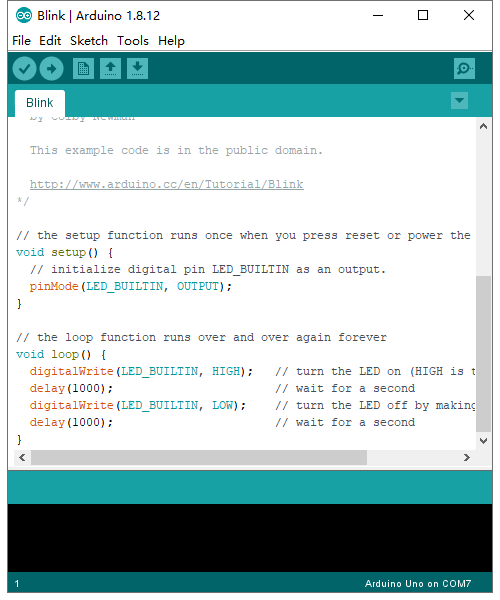

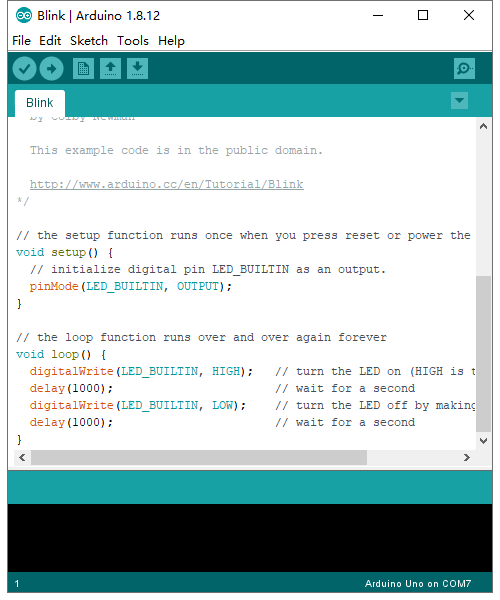

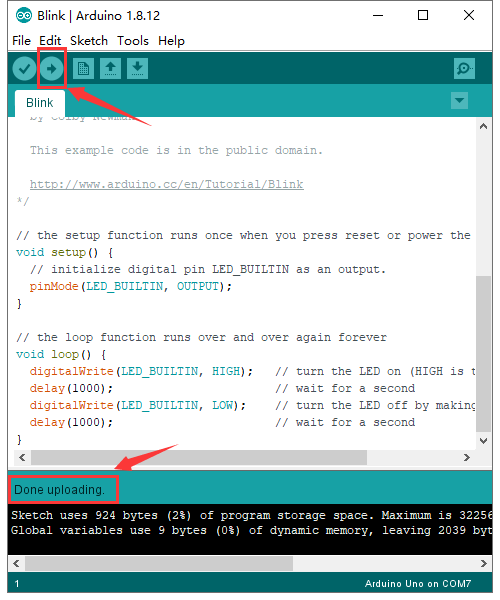

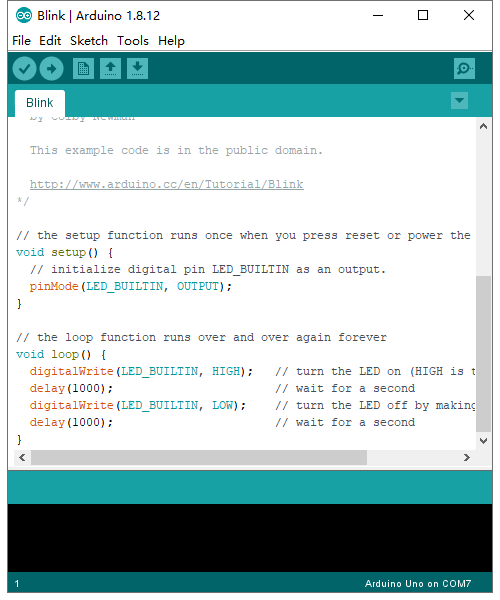

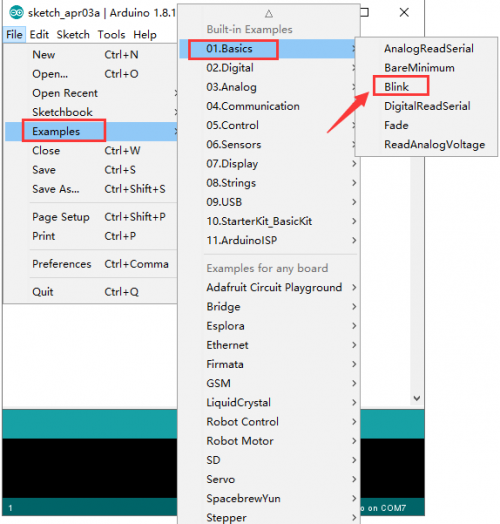

Open the file to select Example, choose BLINK from BASIC, as shown below:

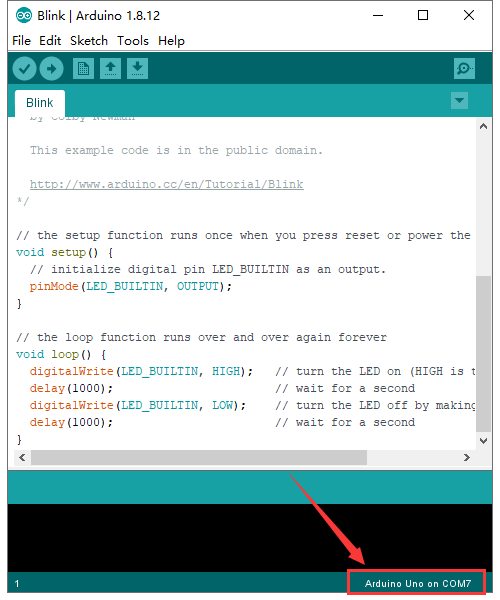

Set board and COM port, the corresponding board and COM port are shown on the lower right of IDE.

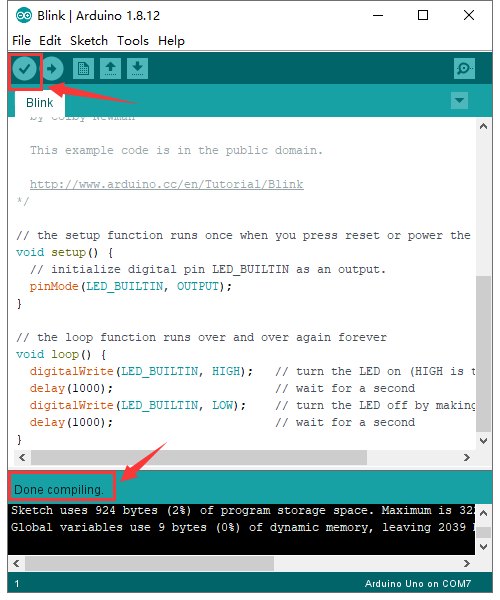

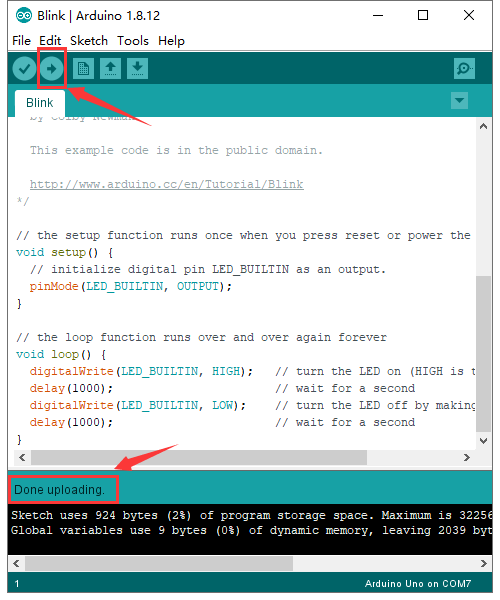

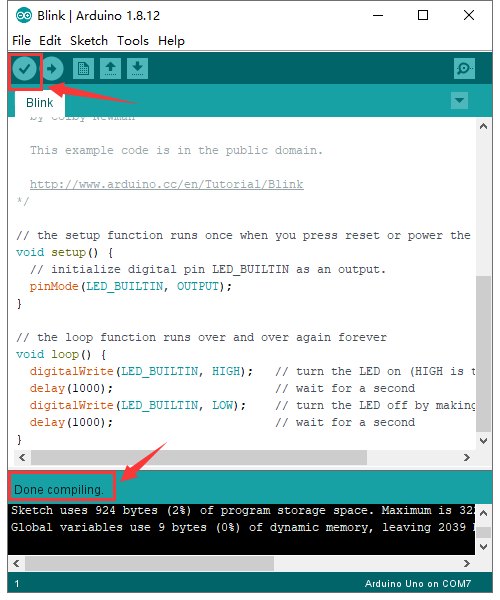

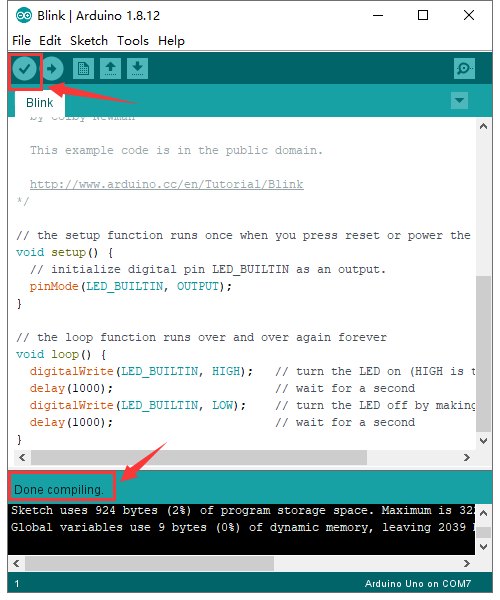

Click to start compiling the program, check errors.

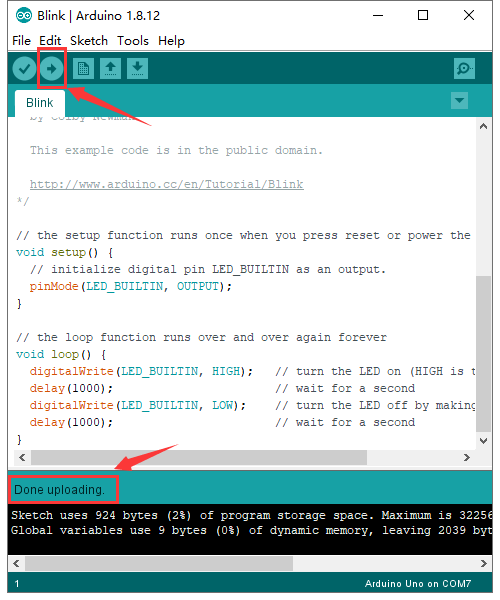

Click to upload the program, upload successfully.

Upload the program successfully, the onboard LED lights on for 1s, lights off for 1s. Congratulation, you finish the first program.

Add Project Libraries

What are Libraries ?

Libraries are a collection of code that makes it easy for you to connect to a sensor,display, module, etc.

For example, the built-in LiquidCrystal library helps talk to LCD displays. There are hundreds of additional libraries available on the Internet for download.

The built-in libraries and some of these additional libraries are listed in the reference.

How to Install a Library ?

Here we will introduce the most simple way for you to add libraries.

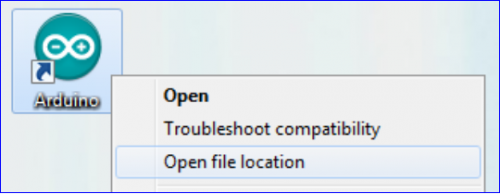

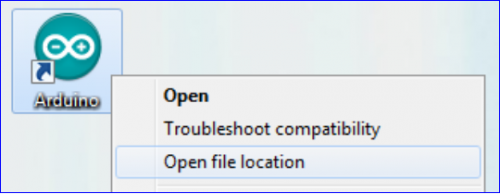

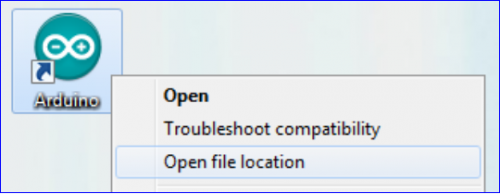

Step 1:After downloading well the Arduino IDE, you can right-click the icon of Arduino IDE.

Find the option «Open file location» shown as below:

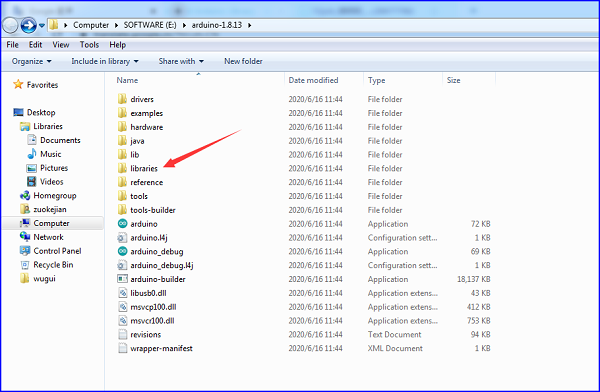

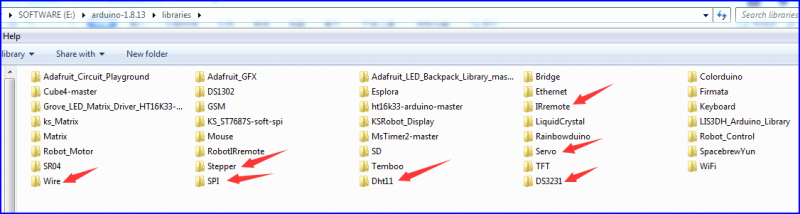

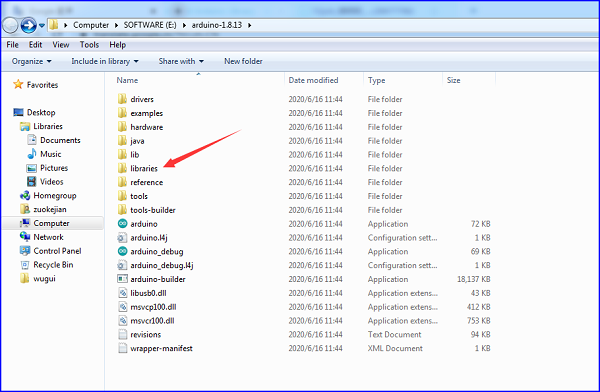

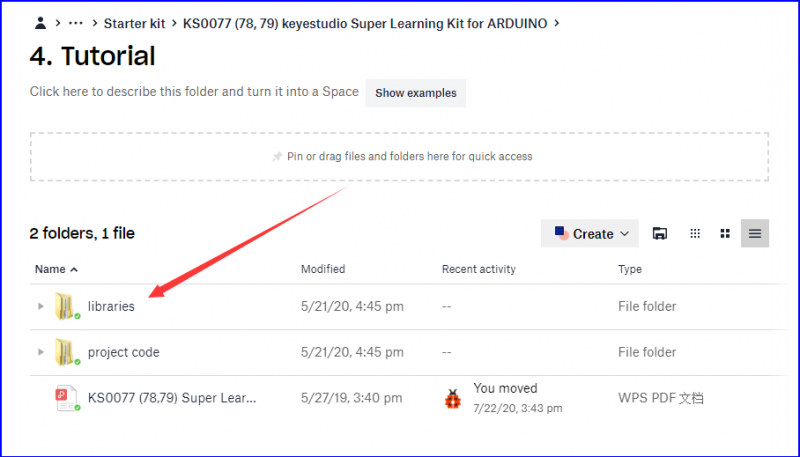

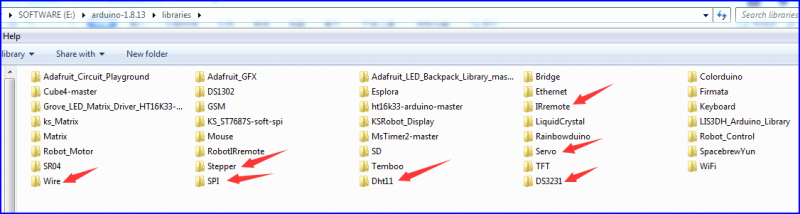

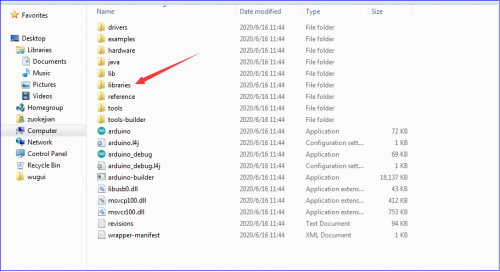

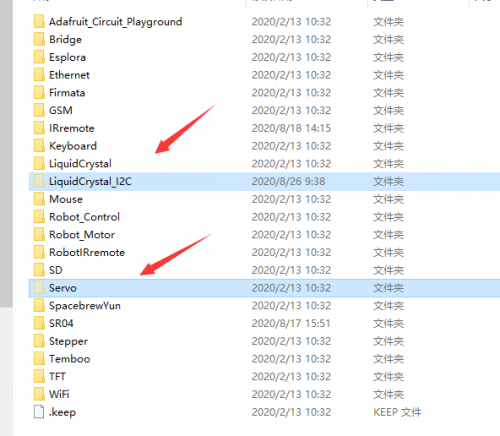

Step 2: Enter it to find out libraries folder which is the library file of Arduino.

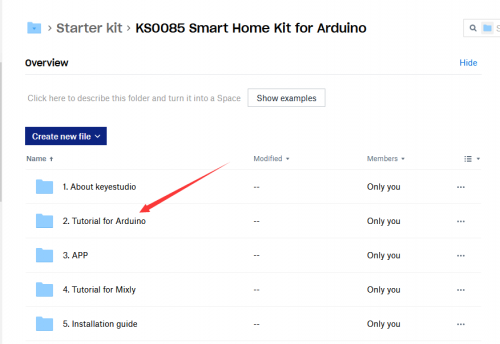

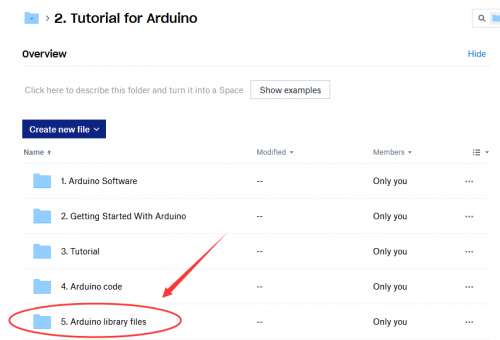

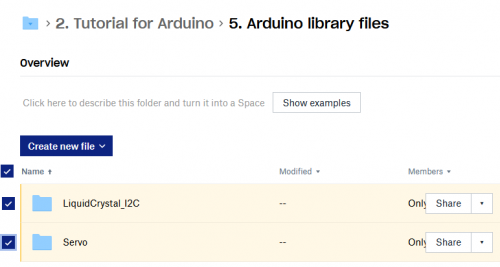

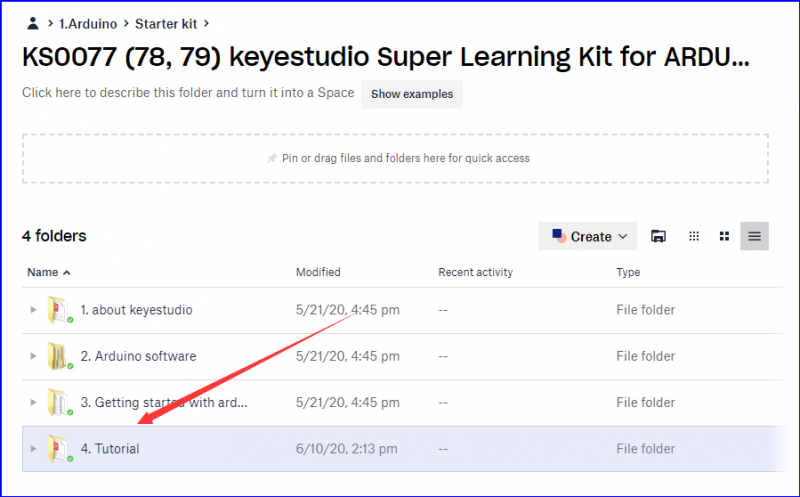

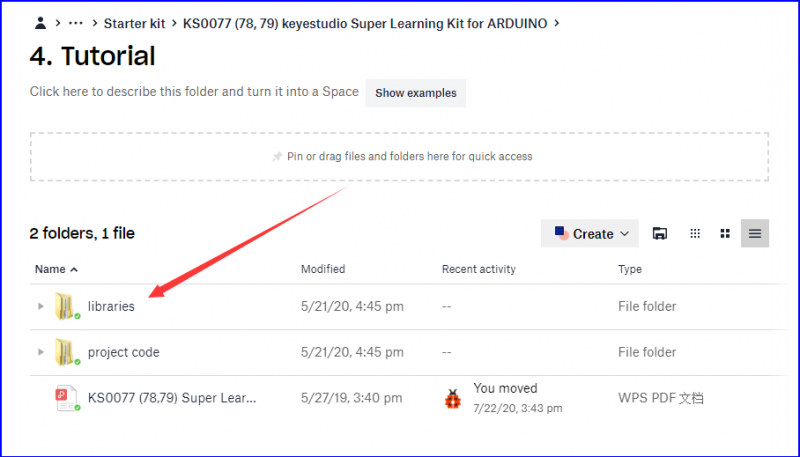

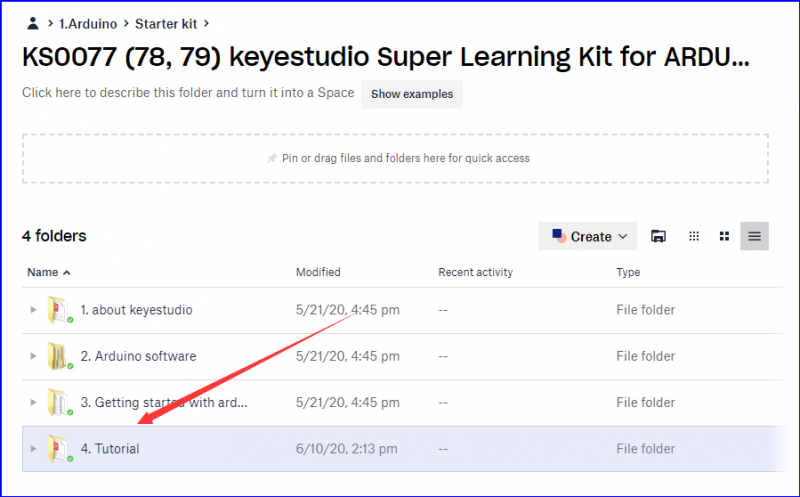

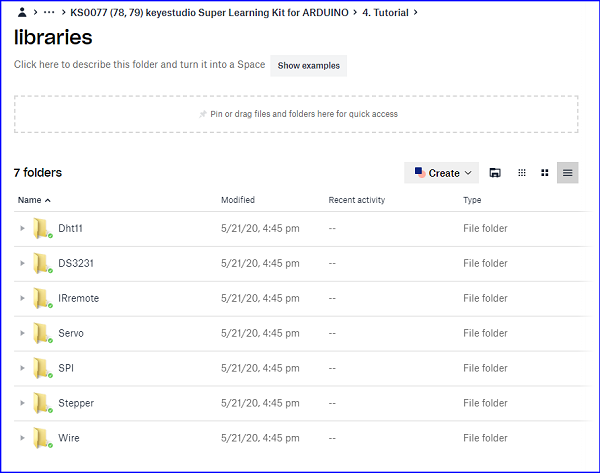

Step 3 Next to find out the “libraries” folder of this kit(seen in the link https://fs.keyestudio.com/KS0077-78-79)

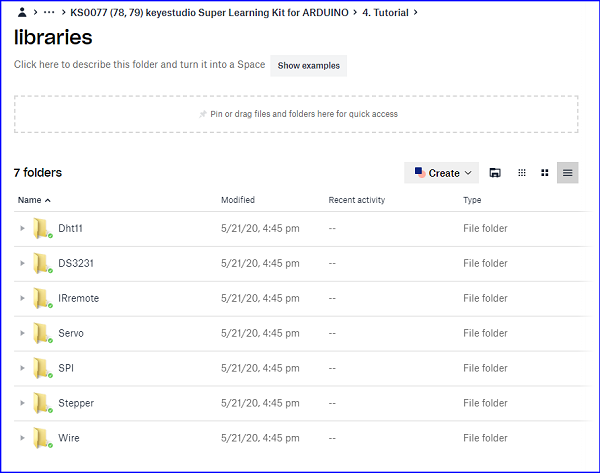

You just need to replicate and paste above libraries into the libraries folder of Arduino IDE.

Then the libraries of this kit are installed successfully, as shown below

Note the Arduino software download and the driver installation of keyetudio Mega 2560 R3 board is similar to arduino V4.0 board.

Project Details

Project 1: Hello World

1.Introduction

As for starters, we will begin with something simple. In this project, you only need an Arduino and a USB Cable to start the «Hello World!» experiment. It is not only a communication test of your Arduino and PC, but also a primer project for you to have your first try in the Arduino world!

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB cable*1

3.Sample Code

After installing driver for Arduino, let’s open Arduino software and compile code that enables Arduino to print «Hello World!» under your instruction. Of course, you can compile code for Arduino to continuously echo «Hello World!» without instruction.

A simple If () statement will do the instruction trick. when Arduino gets an instruction and then to print «Hello World!”.

/*

keyestudio super learning kit

Project 1

Hello World

http//www.keyestudio.com

- /

int val;//define variable val

void setup()

{

Serial.begin(9600);// set the baud rate at 9600 .

}

void loop()

{

val=Serial.read();// read the instruction or character from PC to Arduino, and assign them to Val.

if(val=='R')// determine if the instruction or character received is “R”.

{ // if it’s “R”,

Serial.println("Hello World!");// display“Hello World!”string.

}}//

///////////////////////////////////////////////////////////////

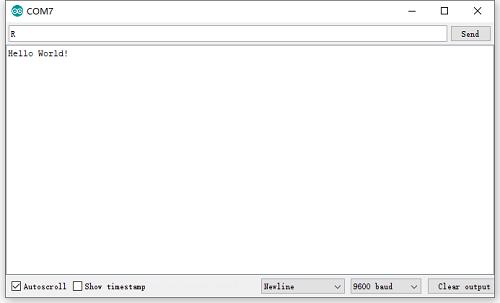

4.Test Result

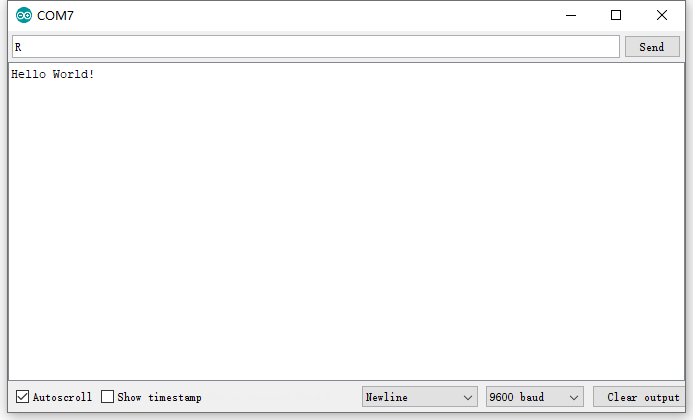

Click to open the serial monitor, input an “R”, PC will receive the information from Arduino Hello World!

After choosing the proper port, the experiment is easy for you!

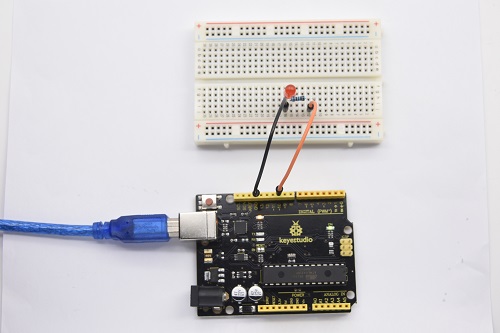

Project 2: LED Blinking

1.Introduction

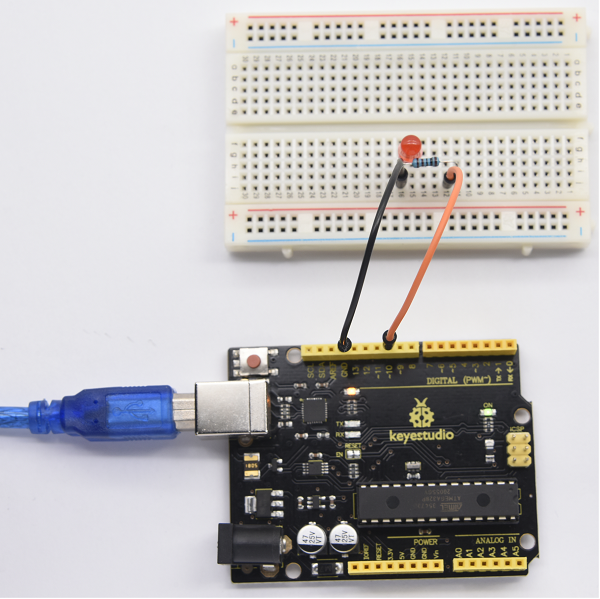

Blinking LED experiment is quite simple. In the «Hello World!» program, we have come across LED. This time, we are going to connect an LED to one of the digital pins rather than using LED13 soldered to the board. Apart from an Arduino and a USB cable, you will need extra parts as below

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red M5 LED*1

- 220Ω Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

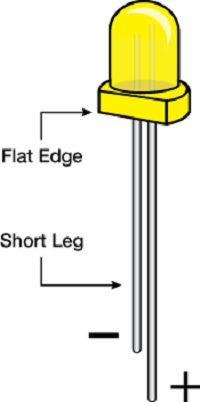

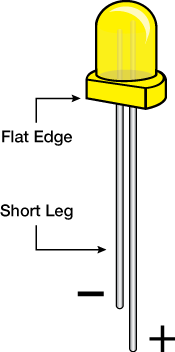

3.Little Knowledge

LED is a type of semiconductor called «Light Emitting Diode «which is an electronic device made of semiconductor materials (silicon, selenium, germanium, etc.). It is dubbed indicator, digital and word display in circuit and device. It has positive and negative poles. The short leg is negative pole, the long one is positive pole.

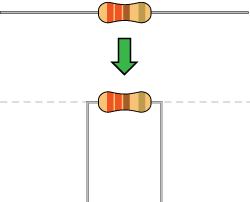

Resistor:Resistor is the electronic component in the circuit, which limits and regulates current flow. Its unit is (Ω).

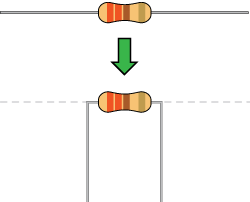

The units larger than ohms are kiloohms (KΩ) and megaohms (MΩ). When in use, in addition to the size of the resistance, you must also pay attention to its power. In the project, the leads at both ends of the resistor should be bent at a 90° angle to fit the breadboard properly. If the lead is too long, it can be cut to an appropriate length.

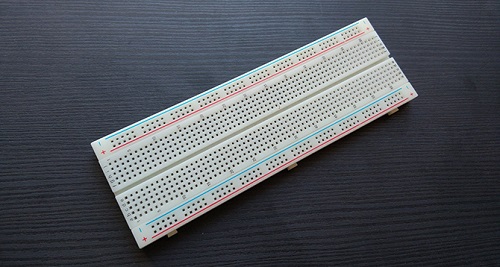

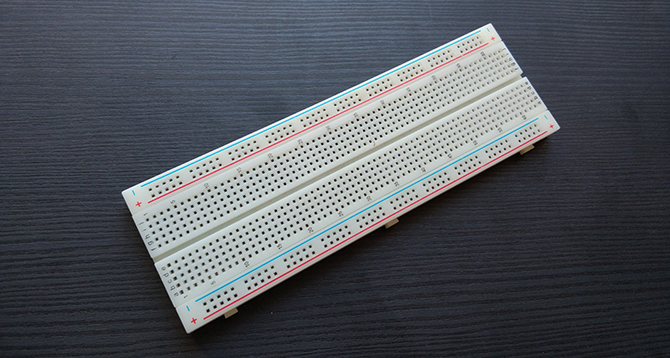

A breadboard is used to build and test circuits quickly before finalizing any circuit design. The breadboard has many holes into which circuit components like ICs and resistors can be inserted. A typical breadboard is shown below:

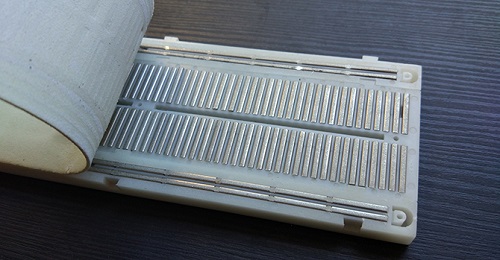

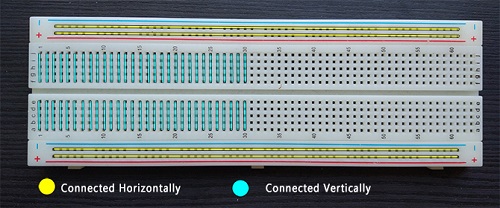

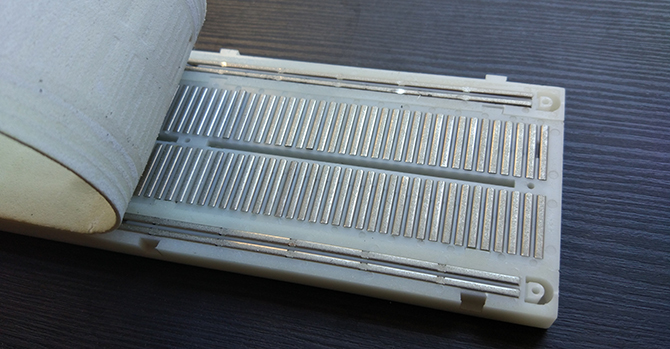

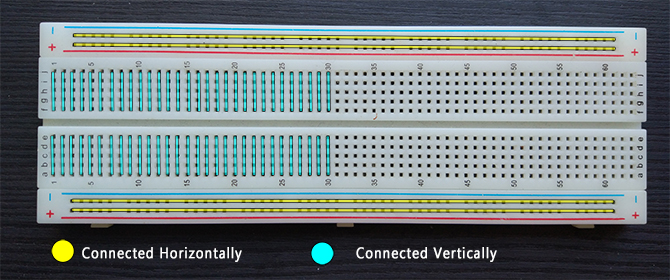

The bread board has strips of metal which run underneath the board and connect the holes on the top of the board. The metal strips are laid out as shown below. Note that the top and bottom rows of holes are connected horizontally while the remaining holes are connected vertically.

To use the bread board, the legs of components are placed in the holes. Each set of holes connected by a metal a strip underneath forms anode

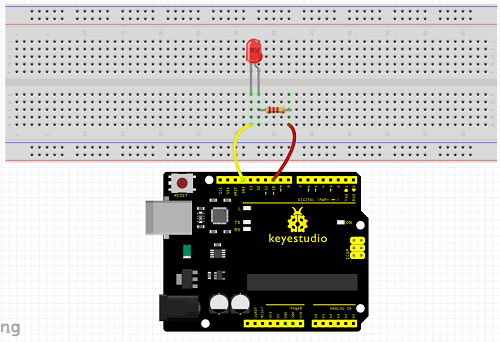

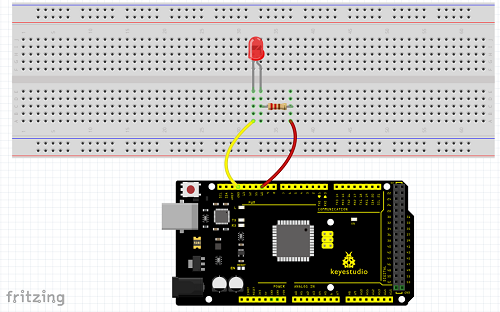

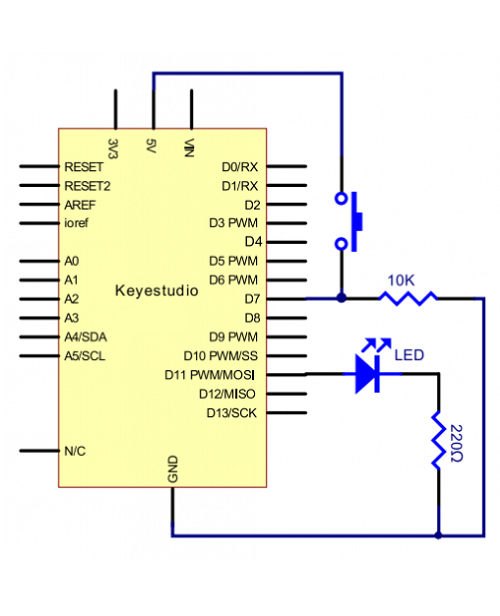

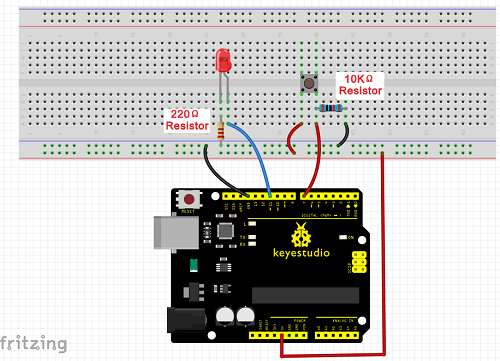

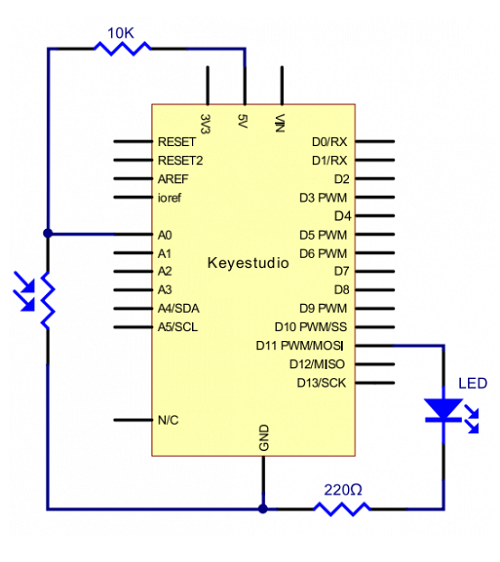

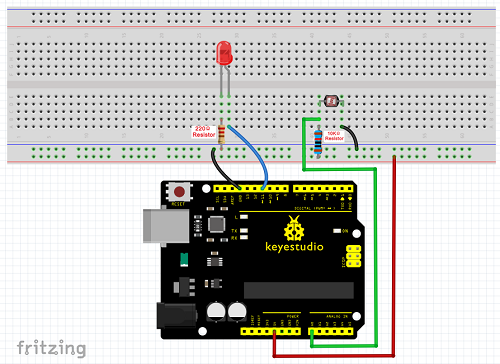

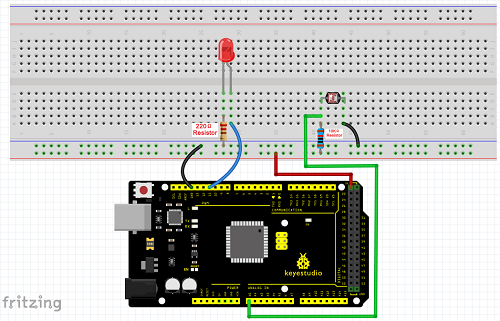

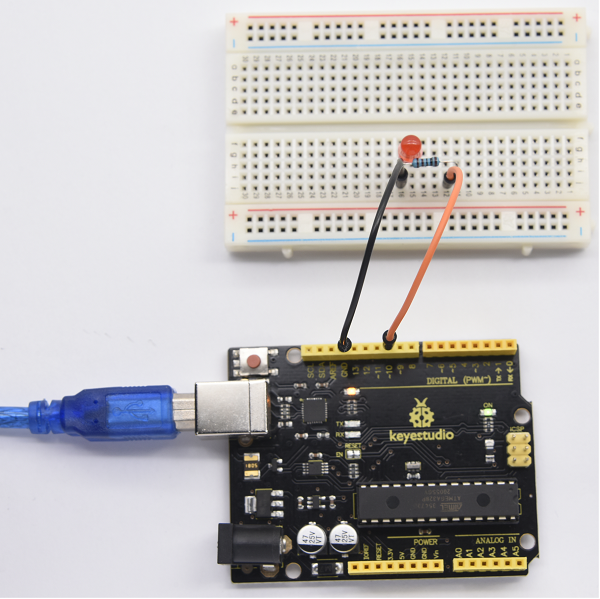

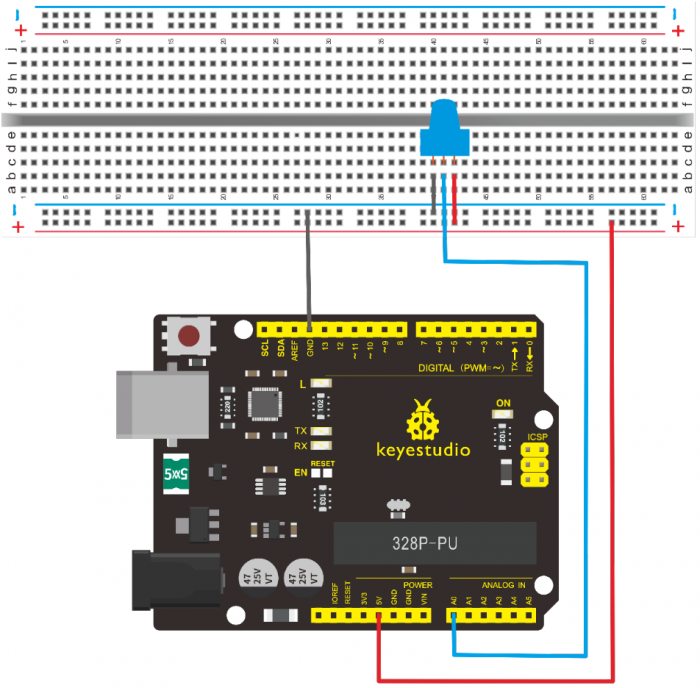

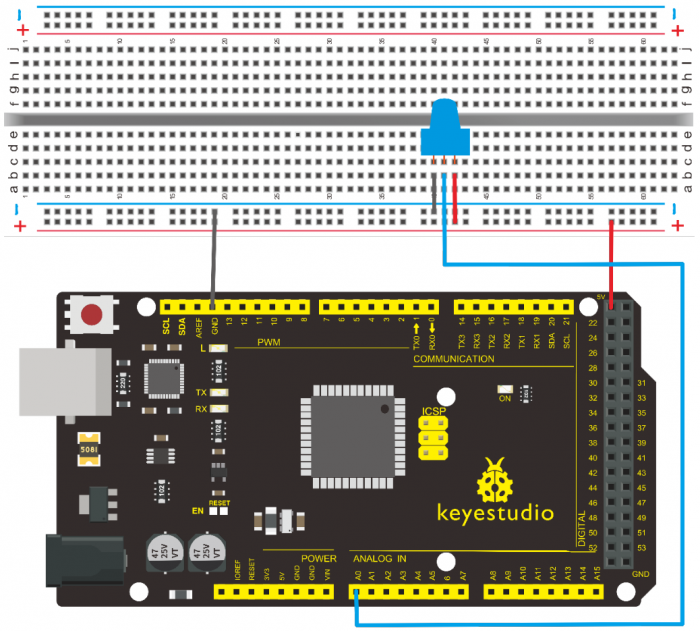

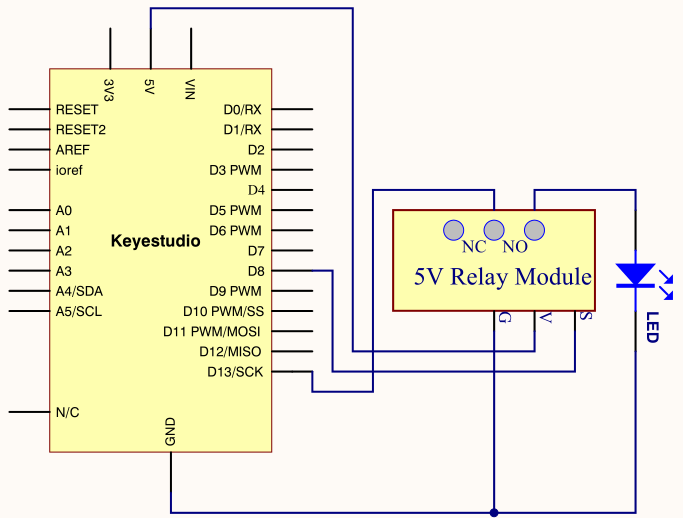

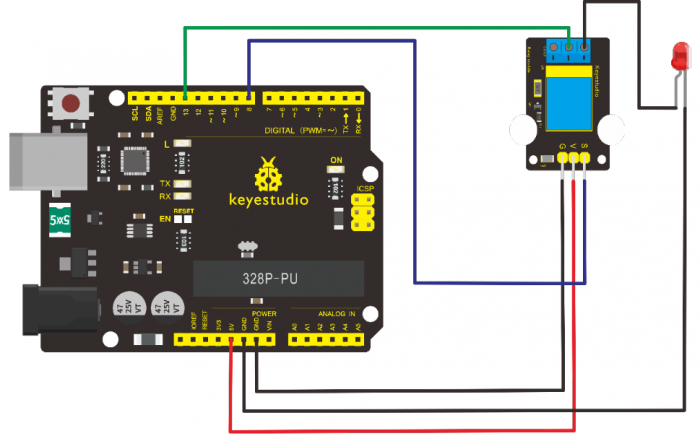

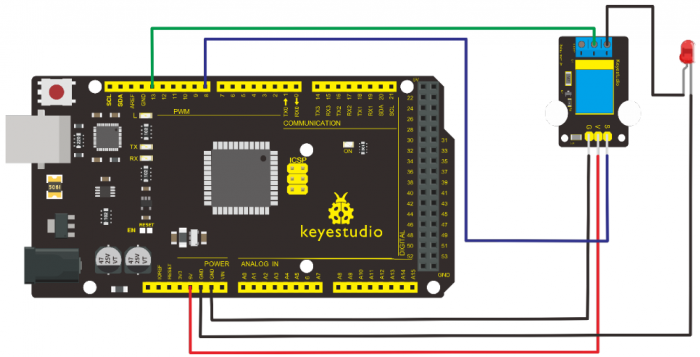

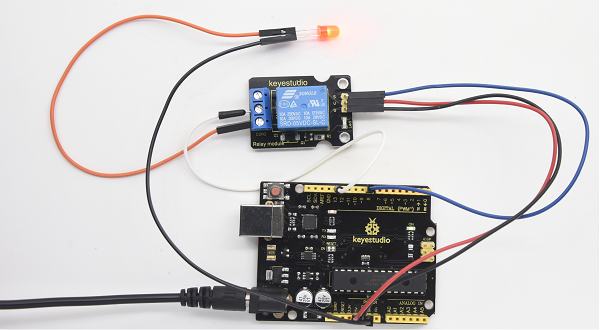

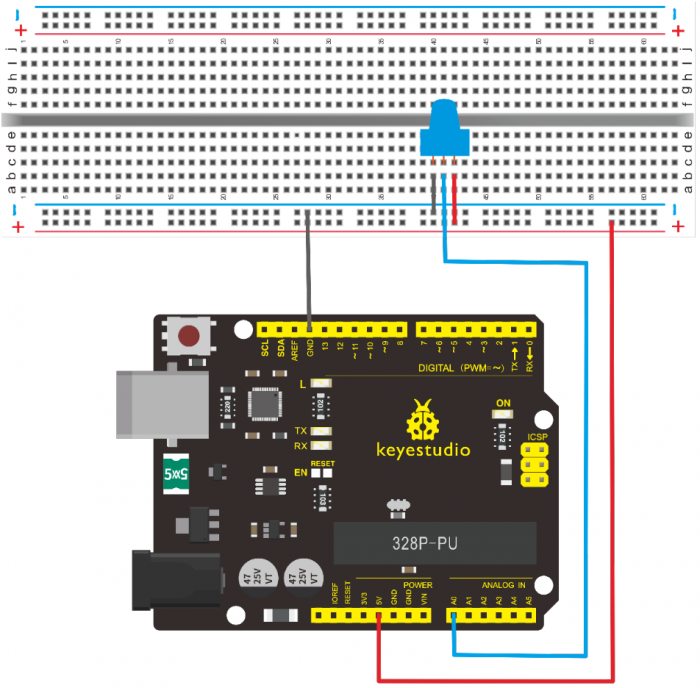

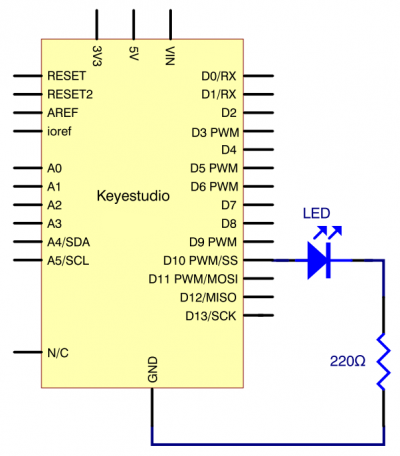

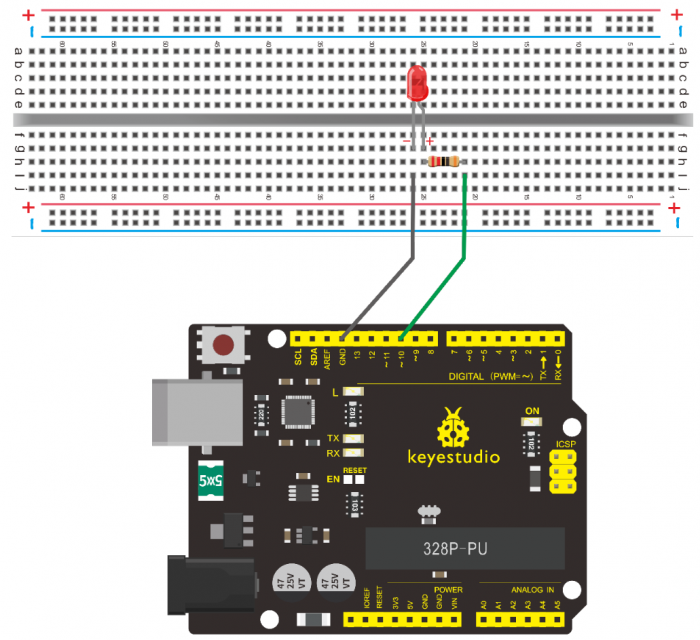

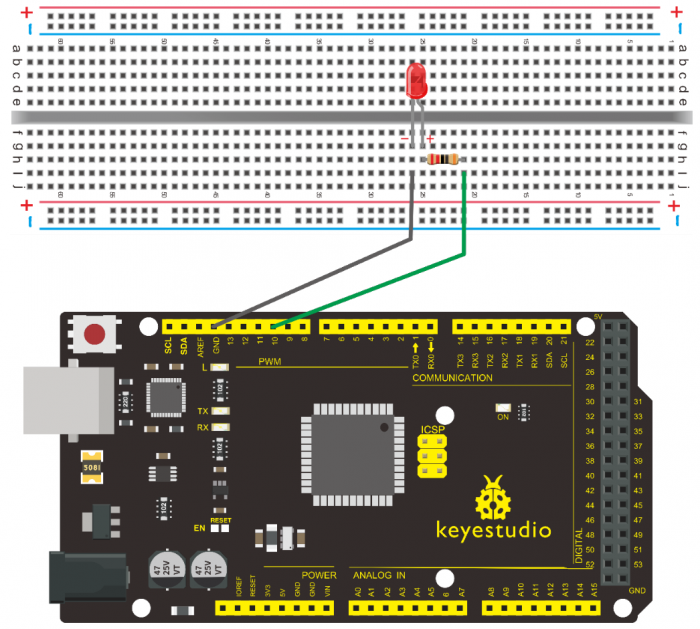

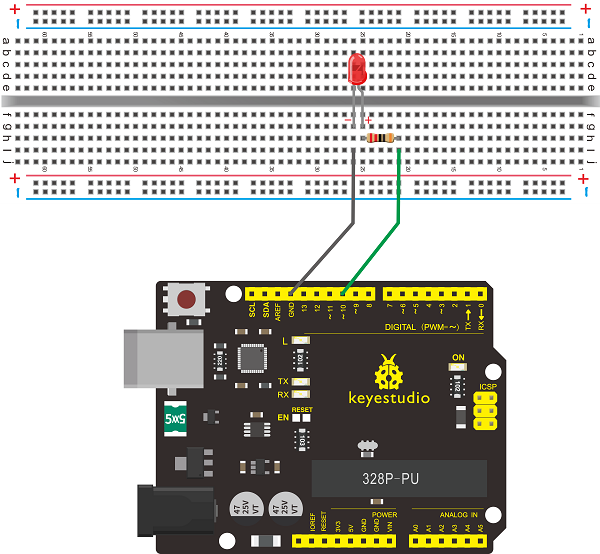

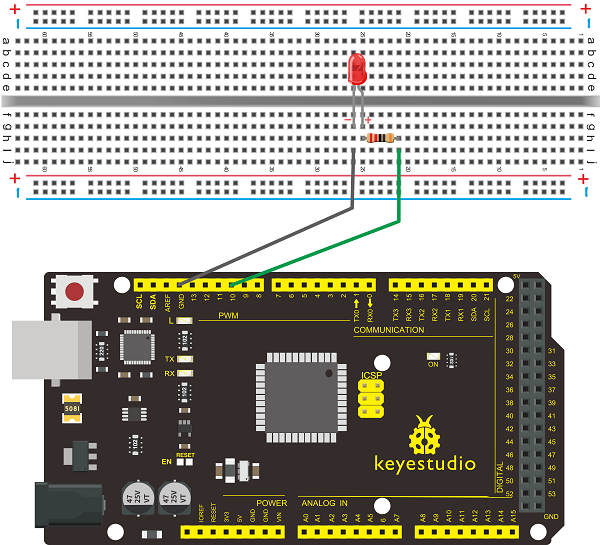

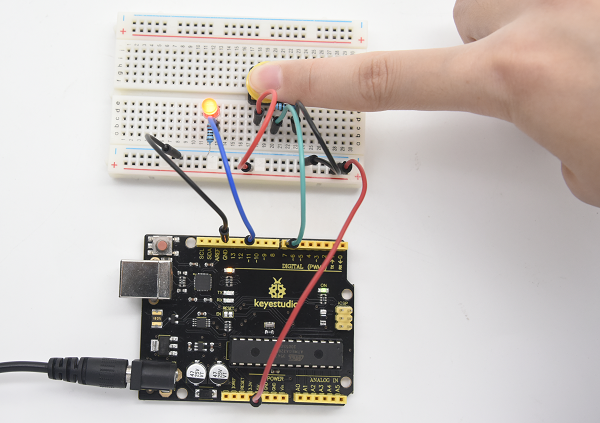

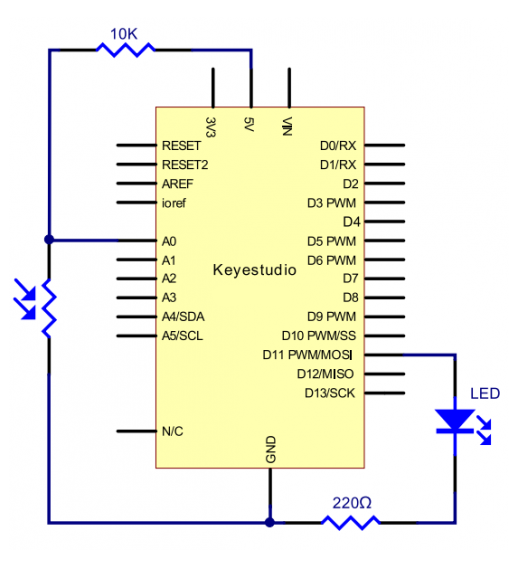

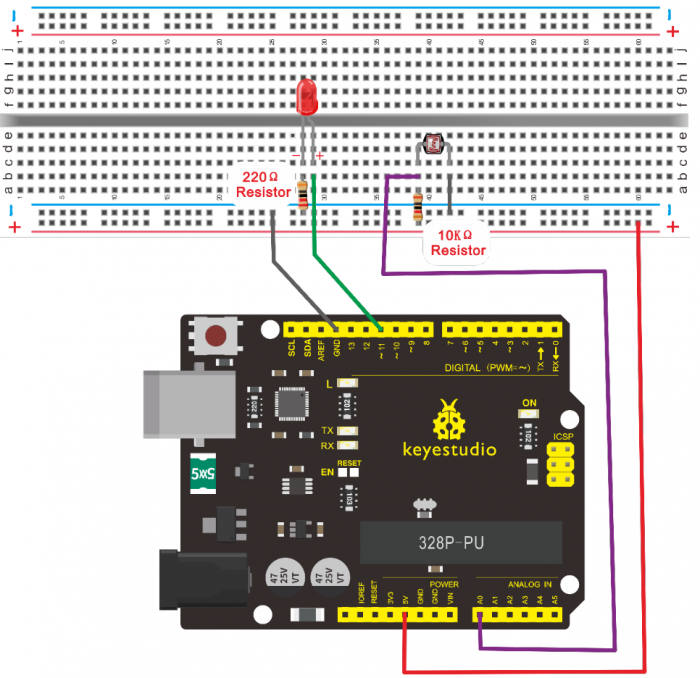

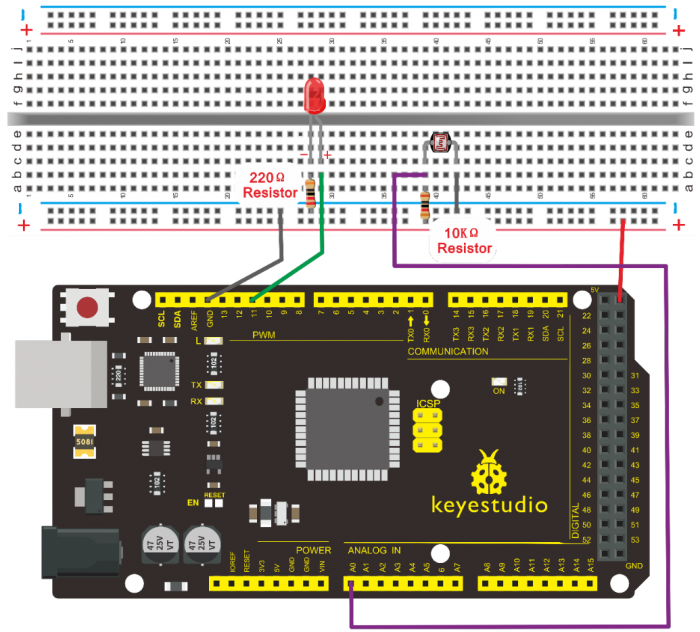

4.Circuit Connection

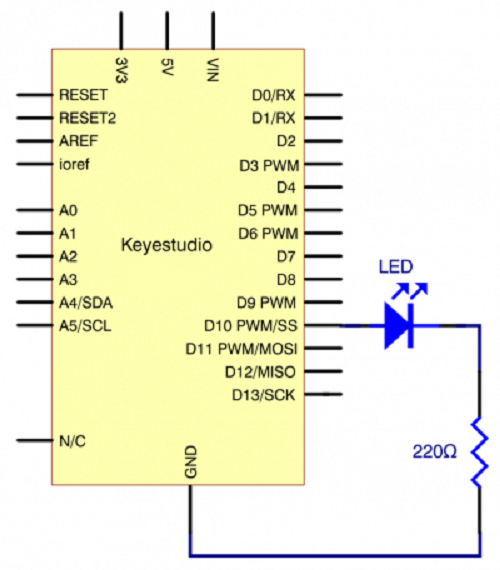

We follow below diagram from the experimental schematic link. Here we use digital pin 10. We connect LED to a 220 ohm resistor to avoid high current damaging the LED.

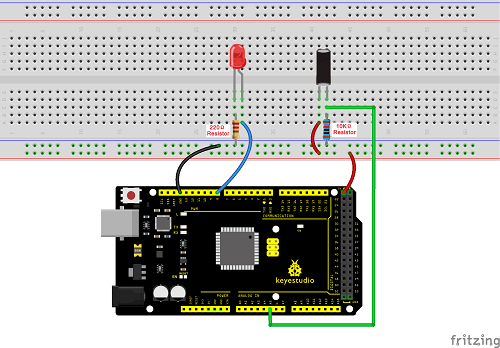

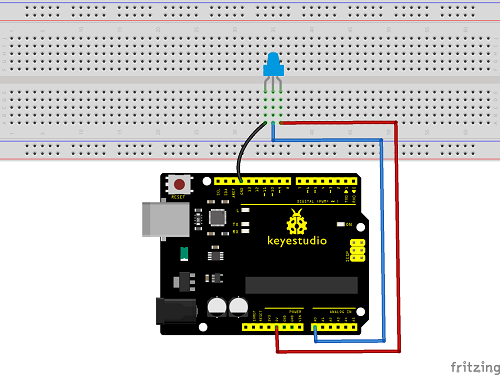

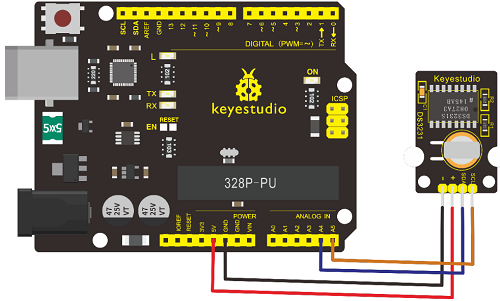

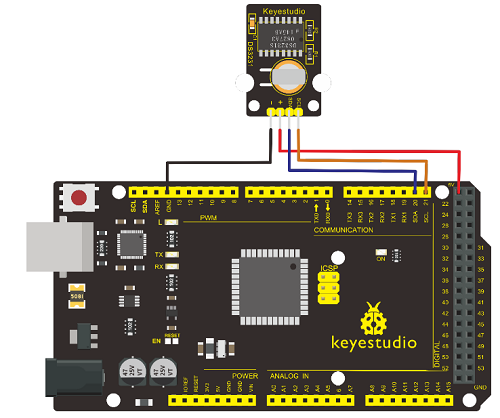

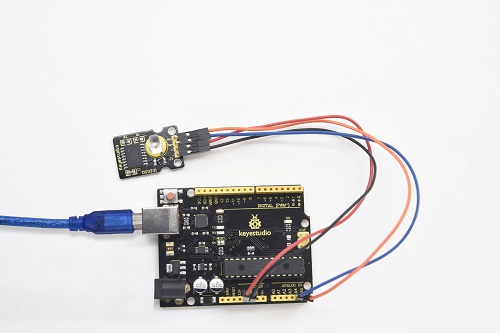

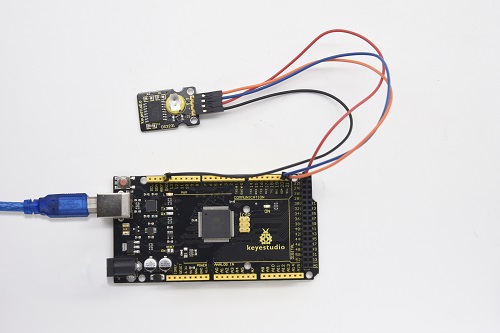

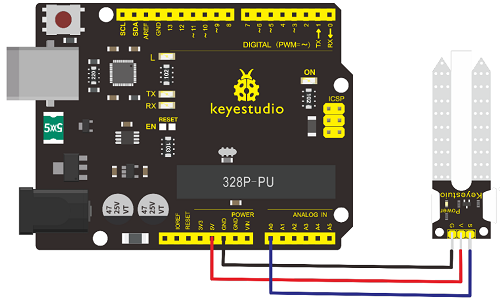

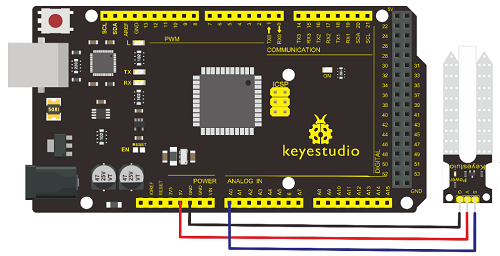

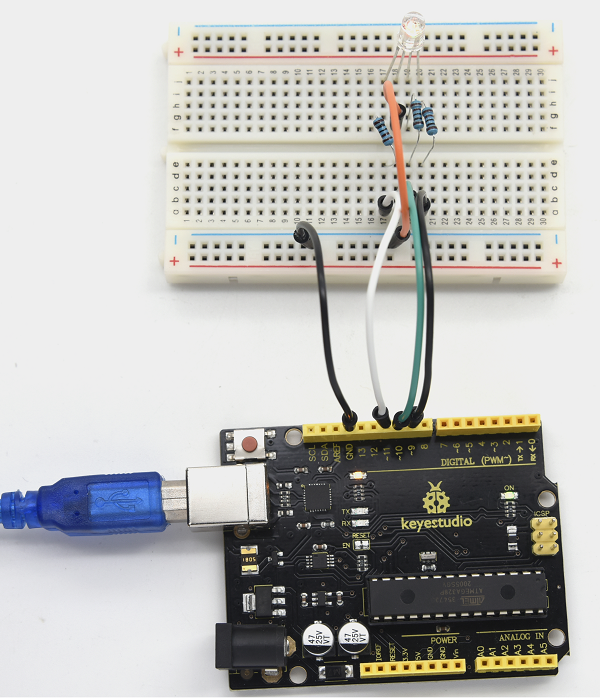

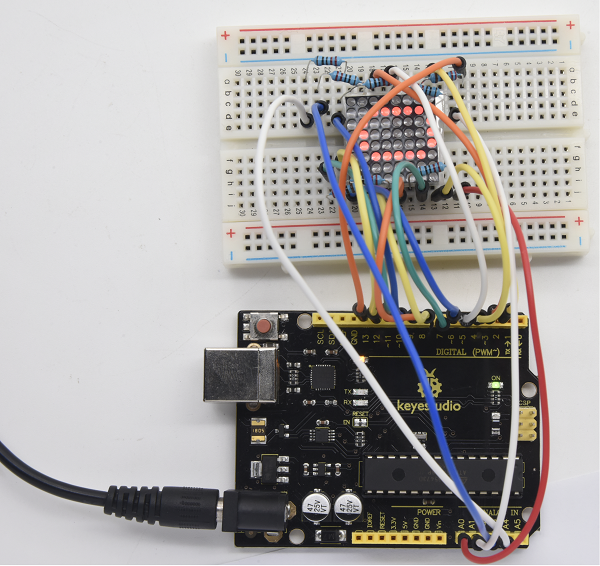

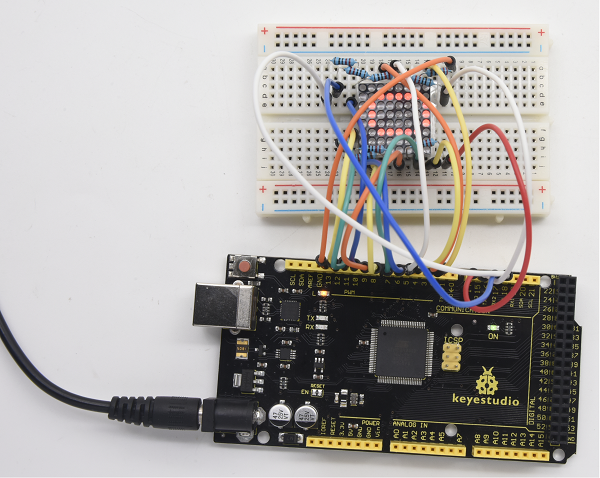

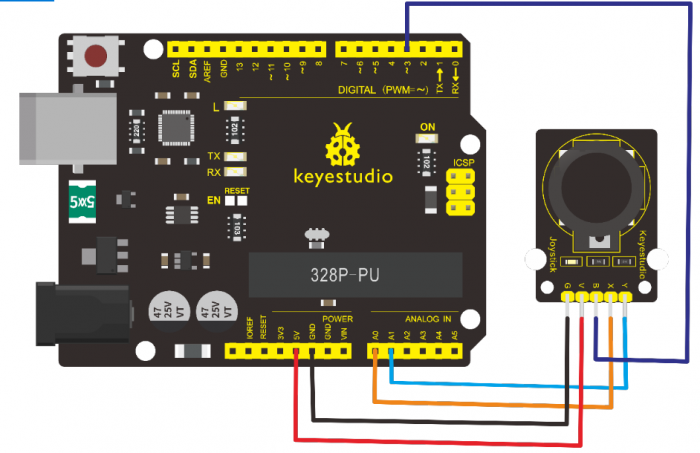

Connection for V4.0

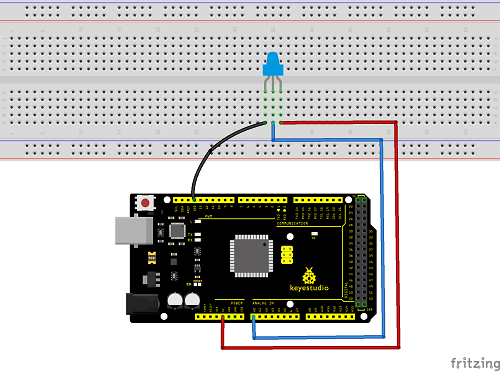

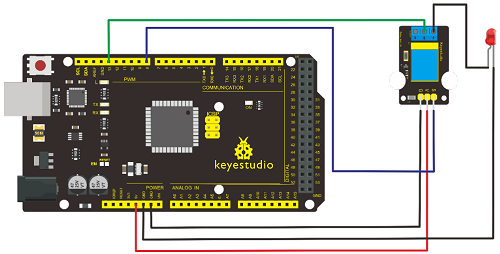

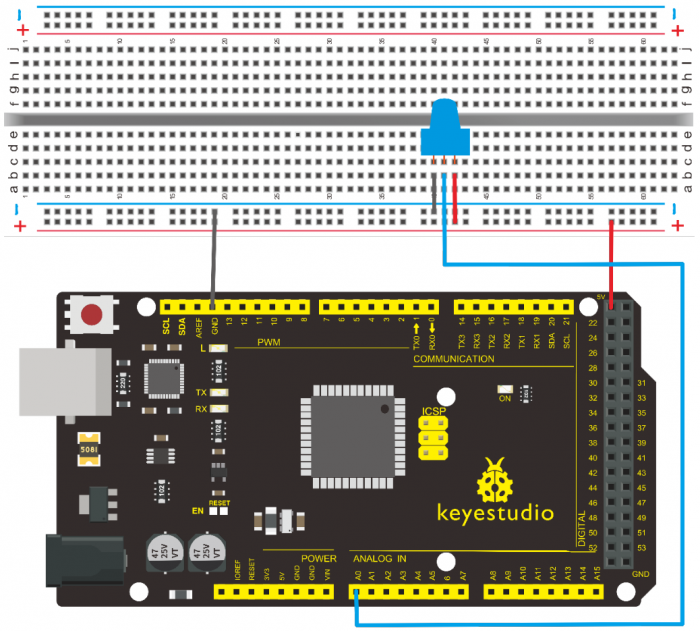

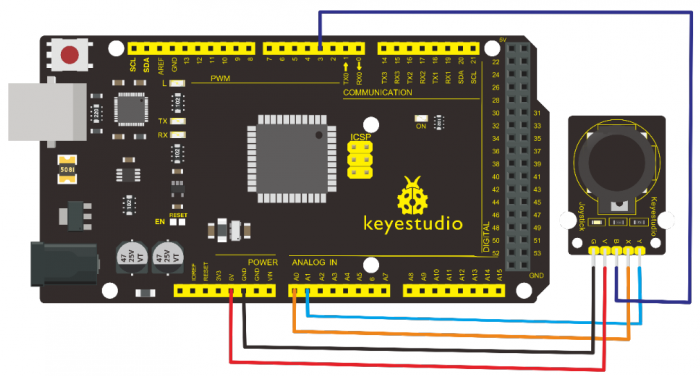

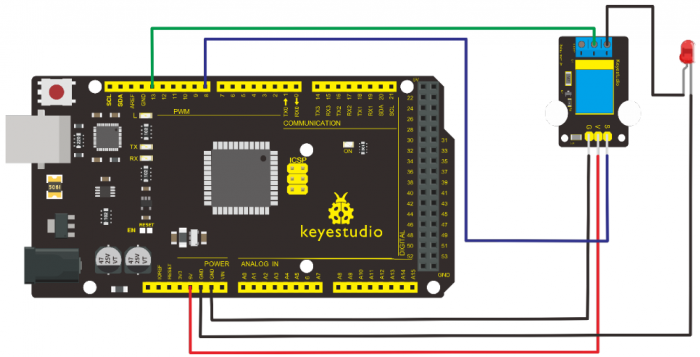

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 2

Blink

http//www.keyestudio.com

- /

int ledPin = 10; // define digital pin 10.

void setup()

{

pinMode(ledPin, OUTPUT);// define pin with LED connected as output.

}

void loop()

{

digitalWrite(ledPin, HIGH); // set the LED on.

delay(1000); // wait for a second.

digitalWrite(ledPin, LOW); // set the LED off.

delay(1000); // wait for a second

}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading this program, in the experiment, you will see the LED connected to pin 10 turning on and off, with an interval of approximate one second.

In this way, blinking LED experiment is now completed. Thank you!

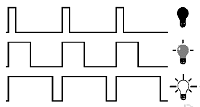

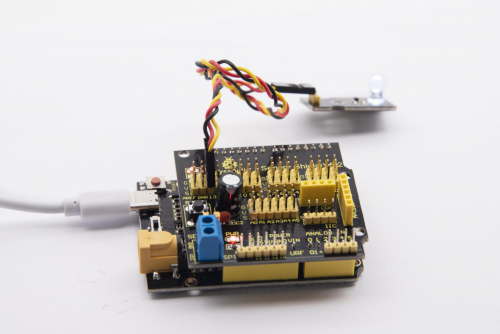

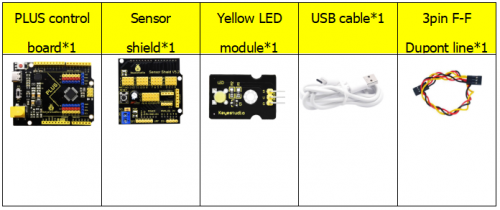

Project 3: PWM

1.Introduction

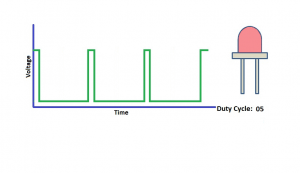

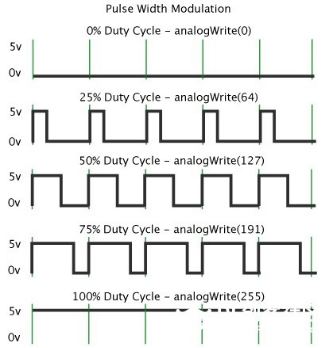

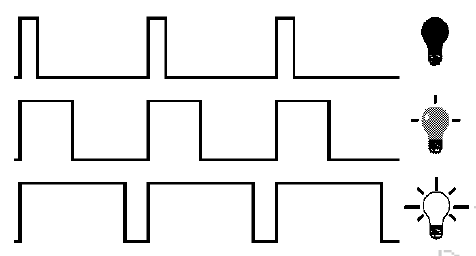

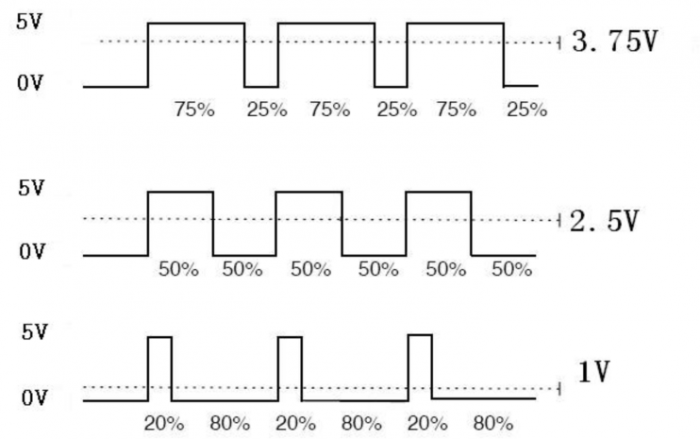

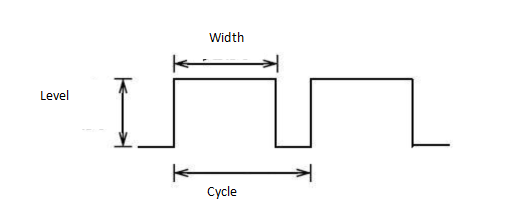

PWM, short for Pulse Width Modulation, is a technique used to encode analog signal level into digital ones. A computer cannot output analog voltage but only digital voltage values such as 0V or 5V. So we use a high resolution counter to encode a specific analog signal level by modulating the duty cycle of PMW.

2.Working Principle

The PWM signal is also digitalized because in any given moment, fully on DC power supply is either 5V (ON), or 0V (OFF). The voltage or current is fed to the analog load (the device that uses the power) by repeated pulse sequence being ON or OFF. Being on, the current is fed to the load; being off, it’s not. With adequate bandwidth, any analog value can be encoded using PWM. The output voltage value is calculated via the on and off time.

Output voltage = (turn on time/pulse time) * maximum voltage value.

PWM has many applications lamp brightness regulating, motor speed regulating, sound making, etc.

The following are the three basic parameters of PMW.

- 1.The amplitude of pulse width (minimum / maximum)

- 2. The pulse period (The reciprocal of pulse frequency in one second)

- 3. The voltage level(such as 0V-5V)

- There are 6 PMW interfaces on Arduino, namely digital pin 3, 5, 6, 9, 10, and 11.

- In previous experiments, we have done «button-controlled LED», using digital signal to control digital pin, also one about potentiometer.

- This time, we will use a potentiometer to control the brightness of the LED.

3.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red M5 LED*1

- 220Ω Resistor

- Breadboard*1

- Breadboard Jumper Wire*6

- USB cable*1

4.Circuit Connection

Connection for V4.0

Connection for 2560 R3

5.Sample Code

/*

keyestudio super learning kit

Project 3

pwm

http//www.keyestudio.com

*/

int ledPin = 10;

void setup() {

pinMode(ledPin,OUTPUT);

}

void loop(){

for (int value = 0 ; value < 255; value=value+1){

analogWrite(ledPin, value);

delay(5);

}

for (int value = 255; value >0; value=value-1){

analogWrite(ledPin, value);

delay(5);

}

}

//////////////////////////////////////////////////////////////////

6.Test Result

Hook up via connection diagram, upload the code and plug in power. The external LED lights up then gets dark gradually, which looks like human breath.

Project 4: Traffic Light

1.Introduction

In the previous program, we have done the LED blinking experiment with one LED. Now, it’s time to up the stakes to do a bit more complicated experiment-traffic light. Actually, these two experiments are similar. While in this traffic light experiment, we use three LEDs with different colors rather than an LED.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB Cable *1

- Red M5 LED*1

- Yellow M5 LED*1

- Blue M5 LED*1

- 220Ω Resistor *3

- Breadboard*1

- Breadboard Jumper Wire *4

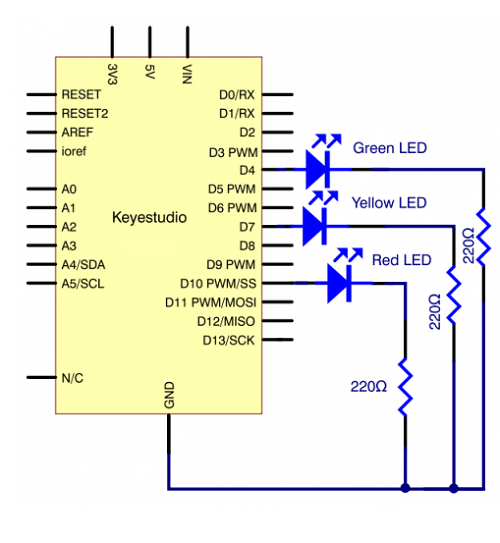

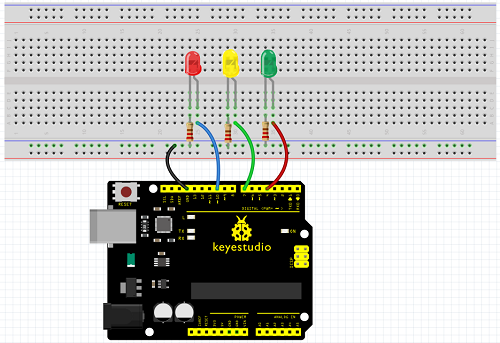

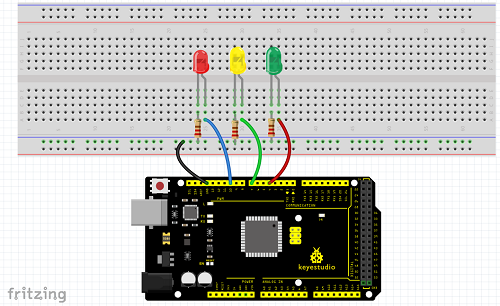

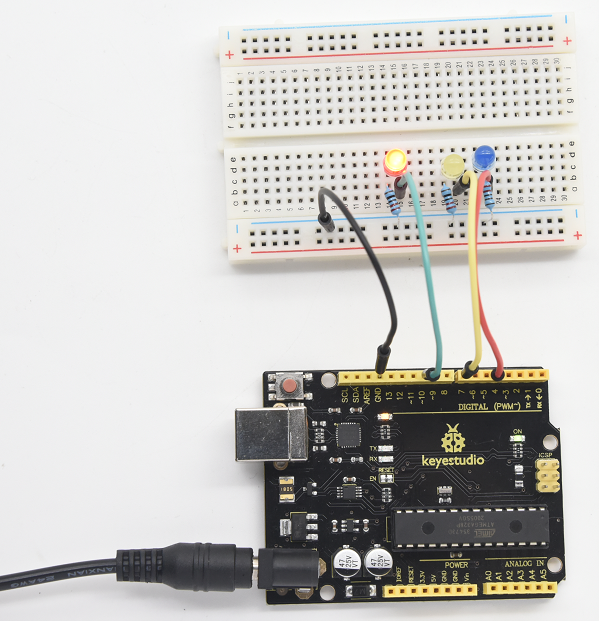

3.Circuit Connection

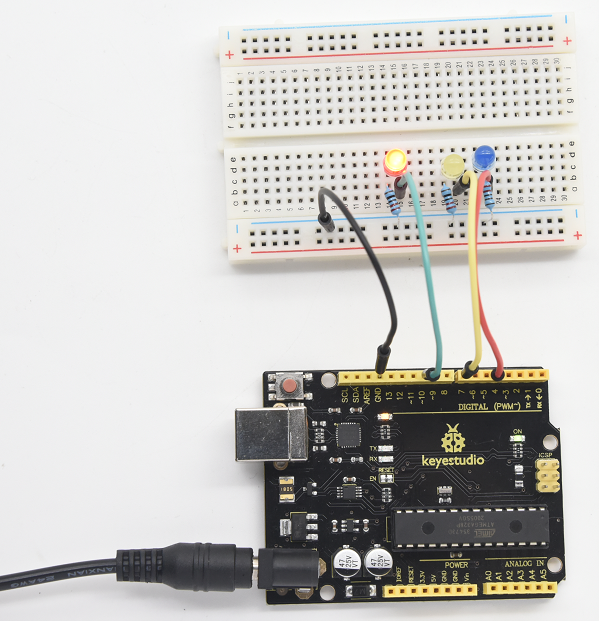

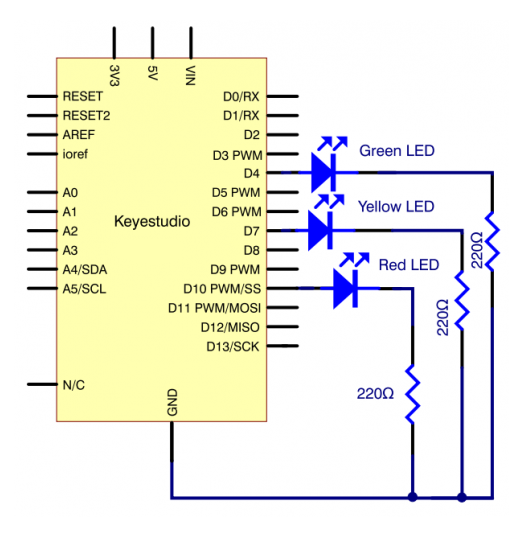

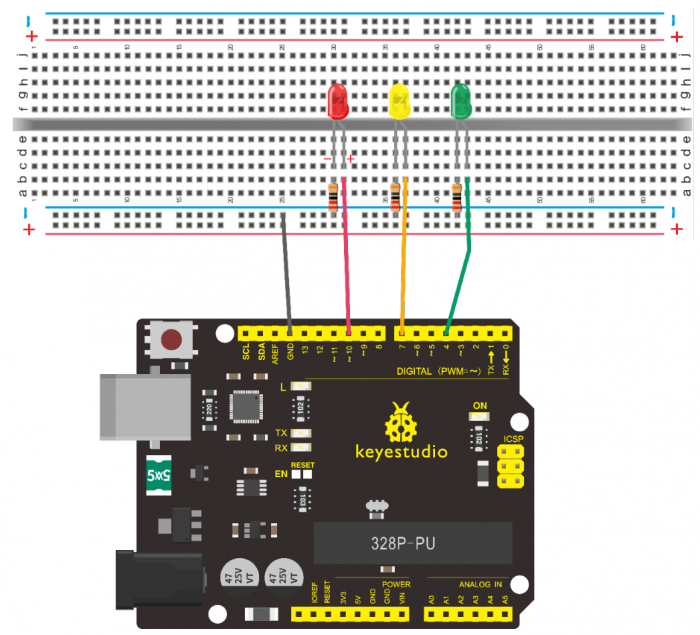

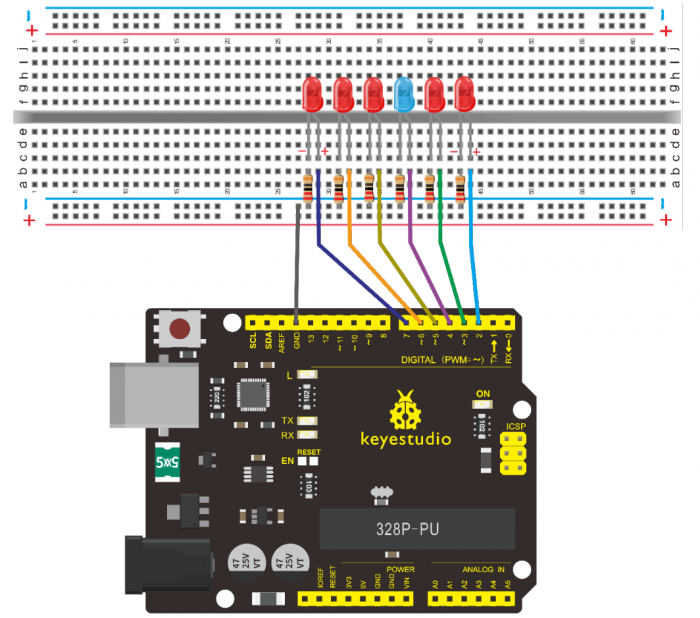

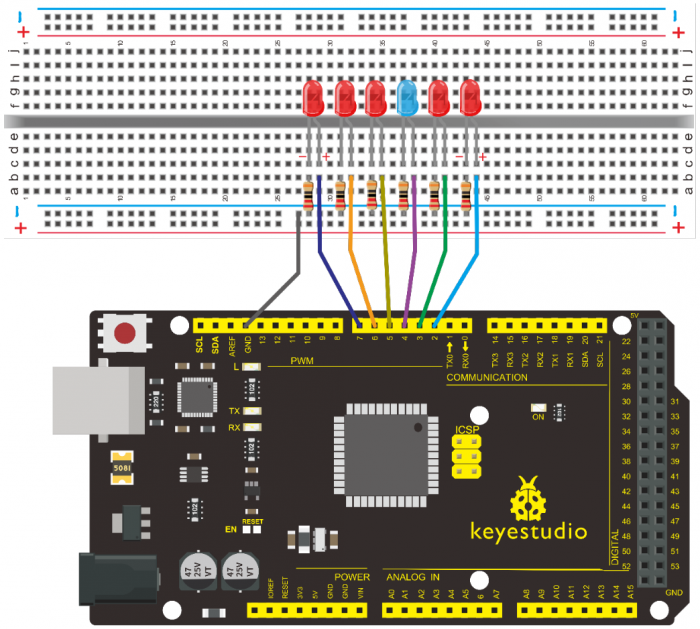

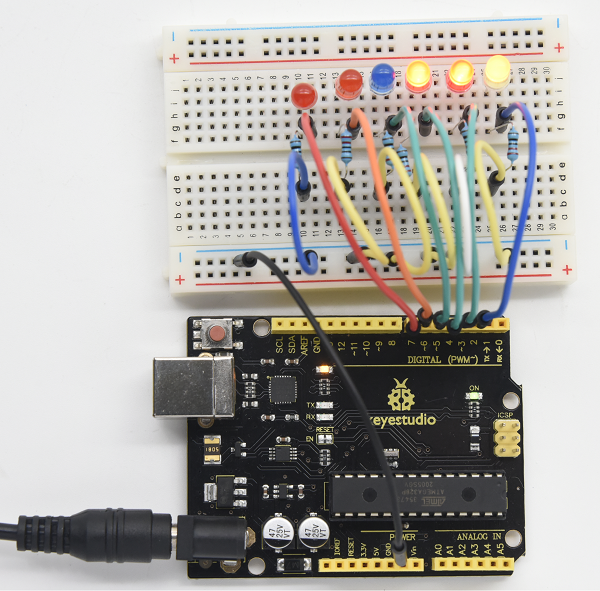

Connection for V4.0

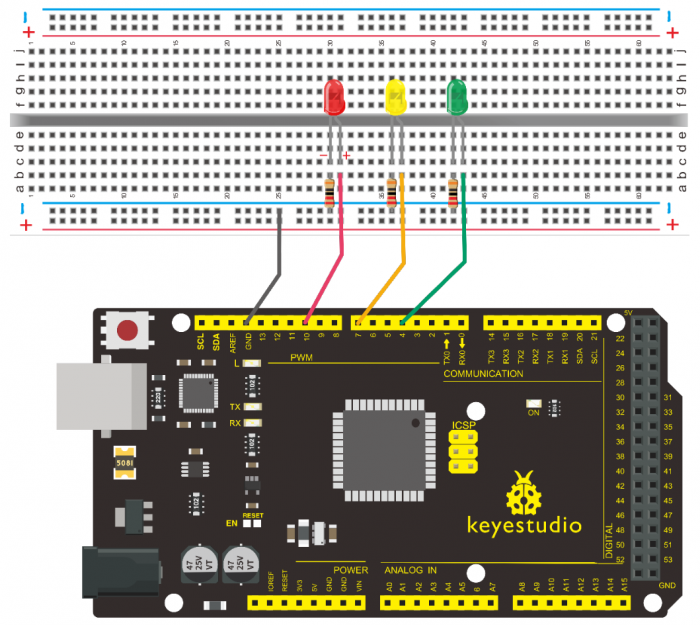

Connection for 2560

4.Sample Code

Since it is a simulation of traffic lights, the blinking time of each LED should be the same with those in traffic lights system.

In this program, we use Arduino delay () function to control delay time, which is much simpler than C language.

/*

keyestudio super learning kit

Project 4

traffic light

http//www.keyestudio.com

*/

int redled =10; // initialize digital pin 10.

int yellowled =7; // initialize digital pin 7.

int blueled =4; // initialize digital pin 4.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(blueled, OUTPUT); // set the pin with blue LED as “output”

}

void loop()

{

digitalWrite(blueled, HIGH);//// turn on blue LED

delay(5000);// wait 5 seconds

digitalWrite(blueled, LOW); // turn off blue LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 second

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 second

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 second

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 second

digitalWrite(redled, LOW);// turn off red LED

}

//////////////////////////////////////////////////////////////////

5.Test Result

When the uploading process is completed, you can see traffic lights of your own design. Note this circuit design is very similar with the one in LED chasing effect.

The blue light will be on for 5 seconds, and then off, followed by the yellow light blinking for 3 times, and then the red light is on for 5 seconds, repeatedly forming a cycle.

Experiment is now completed, thank you!

Project 5: LED Chasing Effect

1.Introduction

We can see many billboards composed of colorful LEDs. They are constantly changing to form various effects. In this experiment, we compile a program to simulate chase effect.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red LED*6

- 220Ω Resistor *6

- Breadboard Jumper Wire*12

- USB cable*1

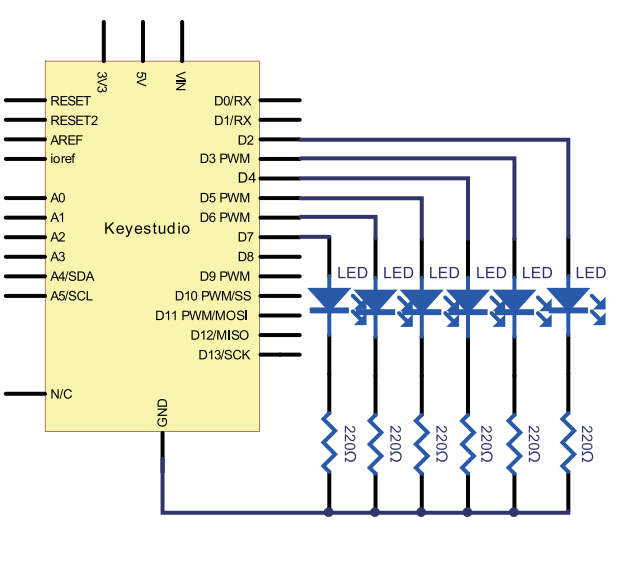

3.Circuit Connection

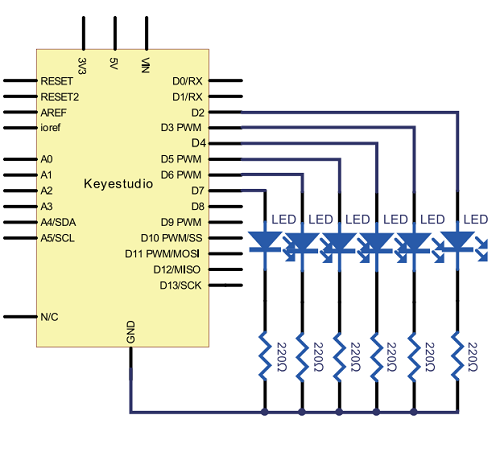

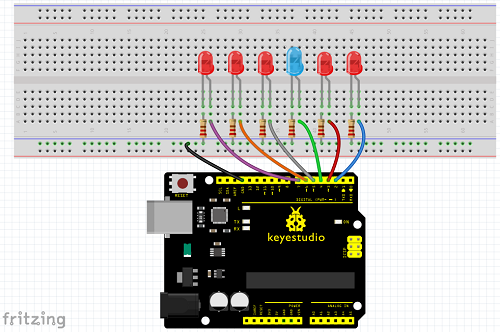

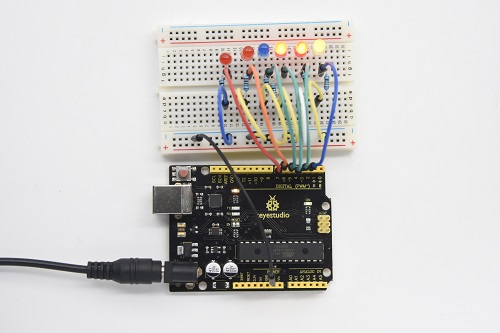

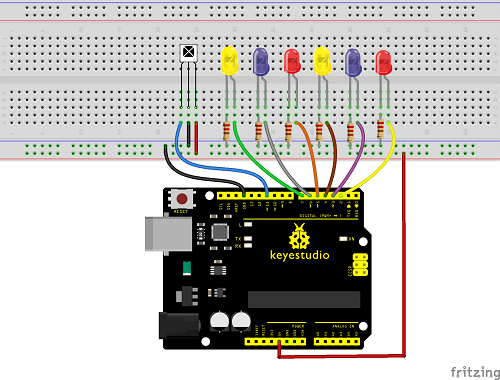

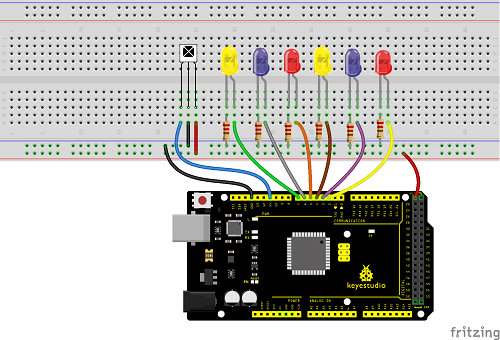

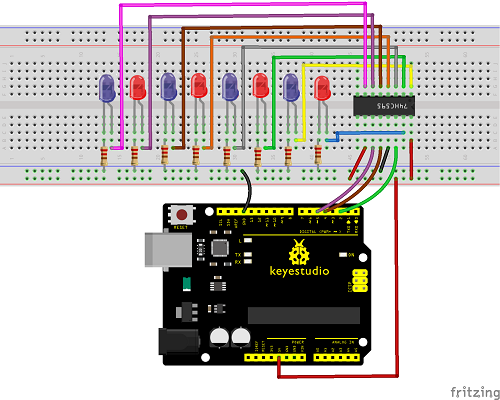

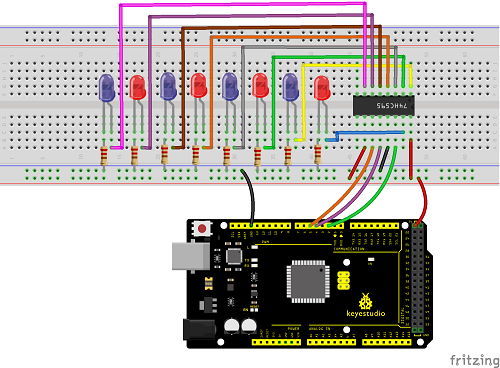

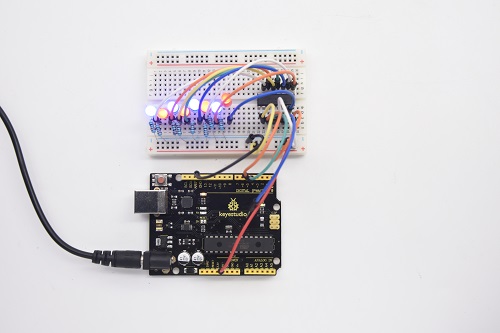

Connection for V4.0

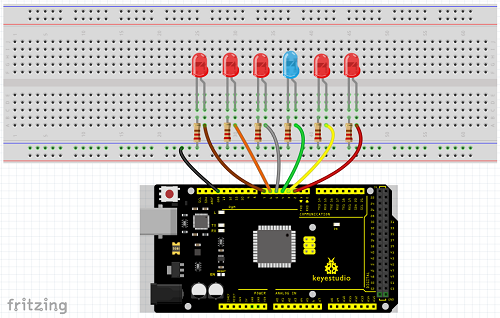

Connection for 2560

4.Sample Code

/*

keyestudio super learning kit

Project 5

LED Chasing Effect

http//www.keyestudio.com

*/

int BASE = 2 ; // the I/O pin for the first LED

int NUM = 6; // number of LEDs

void setup()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

pinMode(i, OUTPUT); // set I/O pins as output

}

}

void loop()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, LOW); // set I/O pins as “low”, turn off LEDs one by one.

delay(200); // delay

}

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, HIGH); // set I/O pins as “high”, turn on LEDs one by one

delay(200); // delay

}

}

//////////////////////////////////////////////////////////////////

5.Test Result

You can see the LEDs blink by sequence.

Project 6: Button-Controlled LED

1.Introduction

I/O port means interface for INPUT and OUTPUT. Up to now, we have only used the OUTPUT function.

In this experiment, we will try to use the INPUT function, which is to read the output value of device connecting to it.

We use 1 button and 1 LED using both input and output to give you a better understanding of the I/O function.

Button switch, familiar to most of us, is a switch value (digital value) component. When it’s pressed, the circuit is in closed (conducting) state.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Button switch*1

- Red M5 LED*1

- 220ΩResistor*1

- 10KΩ Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*6

- USB cable*1

3. Little Knowledge

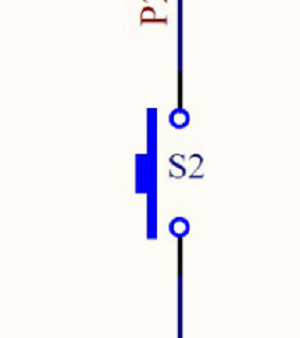

I believe that button switch is common and popular for people. It belongs to switch quantity( digital quantity)component. Composed of normally open contact and normally closed contact,its working principle is similar with ordinary switch.

When the normally open contact bears pressure, the circuit is on state ; however, when this pressure disappears, the normally open contact goes back to initial state, that is, off state. The pressure is the act we switch the button.

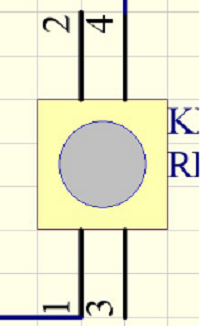

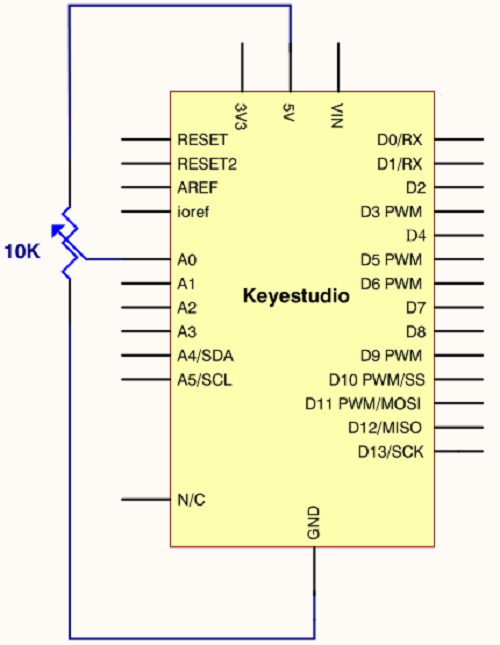

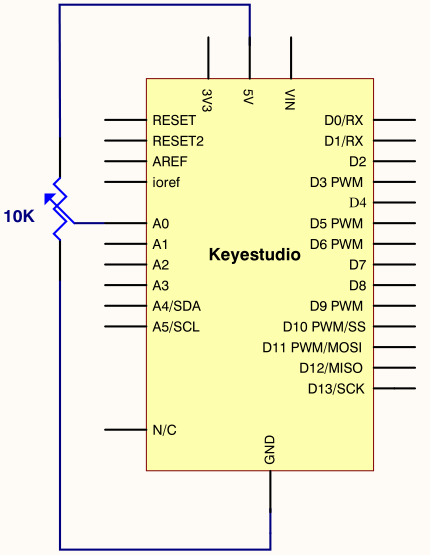

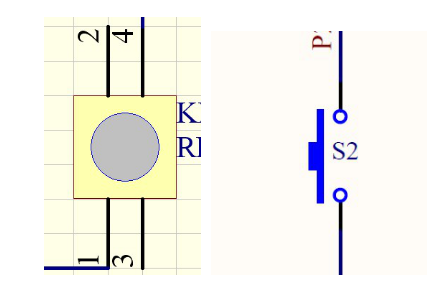

Schematic Diagrams:

4. Circuit Connection

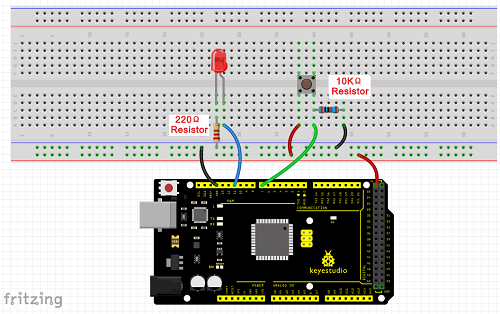

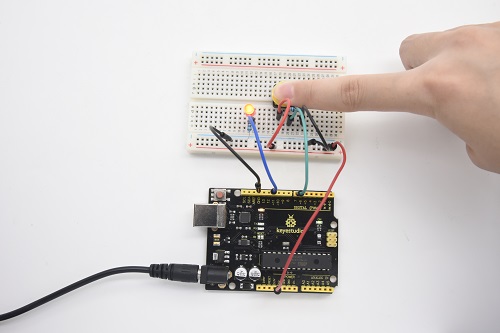

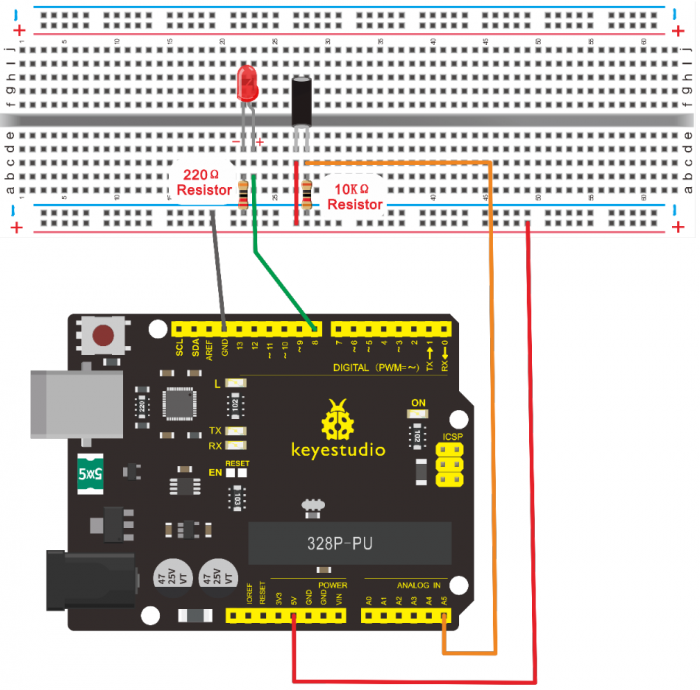

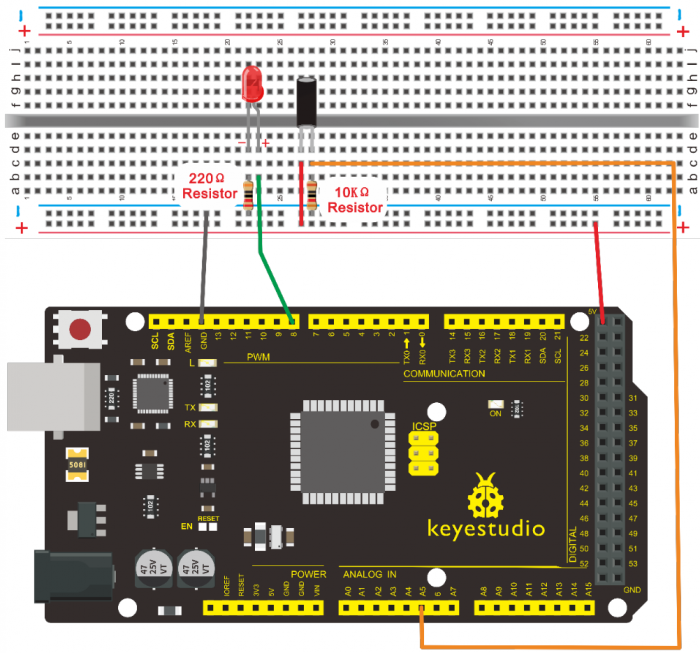

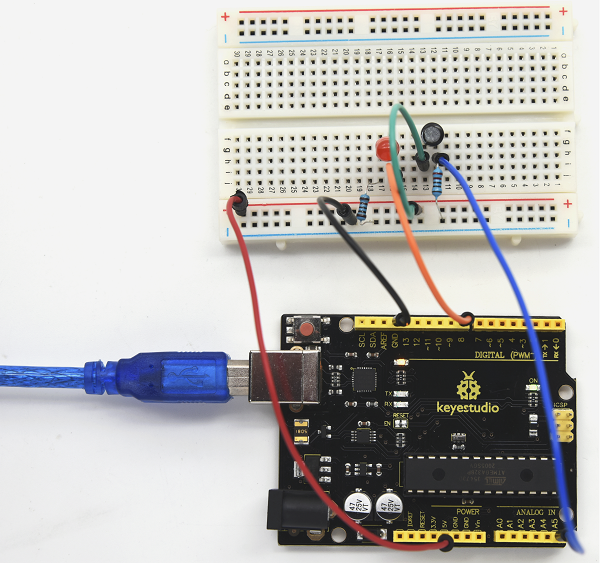

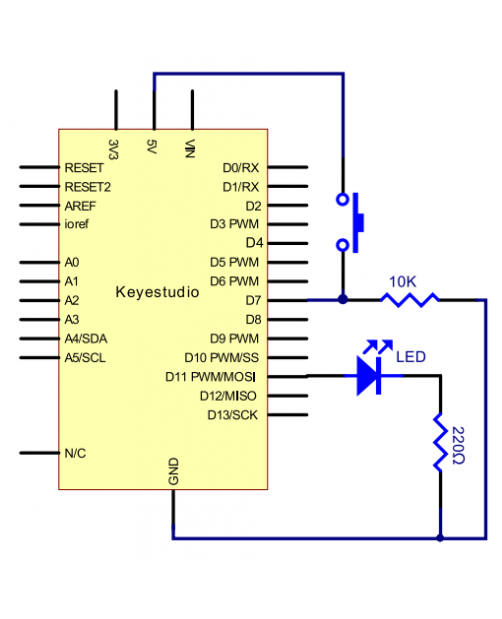

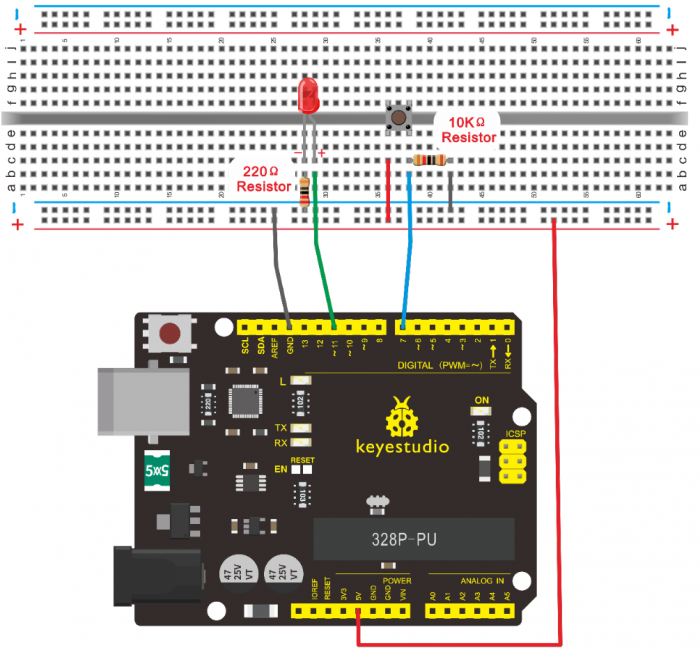

Connection for V4.0

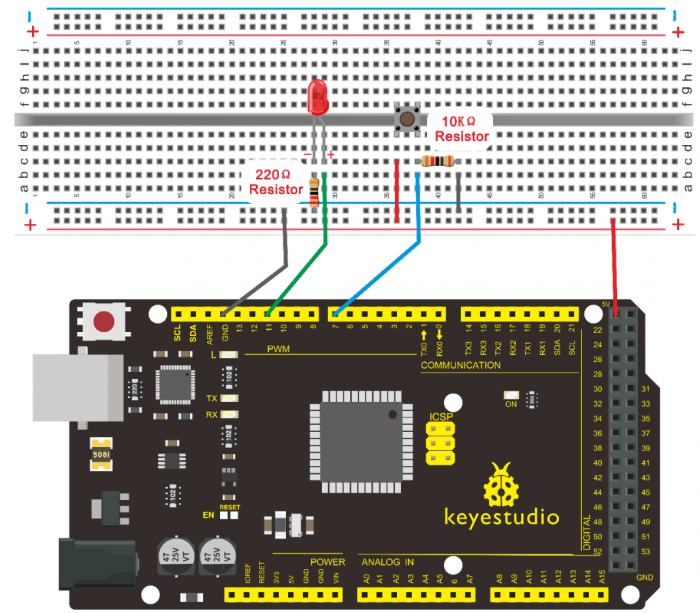

Connection for 2560

5.Sample Code

Now, let’s begin the compiling. When the button is pressed, the LED will be on. Based on the previous study, the coding should be easy for you.

In this program, we add a statement of judgment. Here, we use an if () statement.

Arduino IDE is based on C language, so statements of C language such as while, switch etc. can certainly be used for Arduino program.

When we press the button, pin 7 will output high level. We can program pin 11 to output high level and turn on the LED. When pin 7 outputs low level, pin 11 also outputs low level and the LED remains off.

/*

keyestudio super learning kit

Project 6

Button

http//www.keyestudio.com

*/

int ledpin=11;// initialize pin 11

int inpin=7;// initialize pin 7

int val;// define val

void setup()

{

pinMode(ledpin,OUTPUT);// set LED pin as “output”

pinMode(inpin,INPUT);// set button pin as “input”

}

void loop()

{

val=digitalRead(inpin);// read the level value of pin 7 and assign if to val

if(val==LOW)// check if the button is pressed, if yes, turn on the LED

{ digitalWrite(ledpin,LOW);}

else

{ digitalWrite(ledpin,HIGH);}

}

//////////////////////////////////////////////////////////////////

6.Test Result

When the button is pressed, LED is on, otherwise, LED remains off. In this way, the button controlled LED experiment is completed.

The simple principle of this experiment is widely used in a variety of circuit and electric appliances. You can easily come across it in your daily life. One typical example is when you press a certain key on your phone, the backlight will be on.

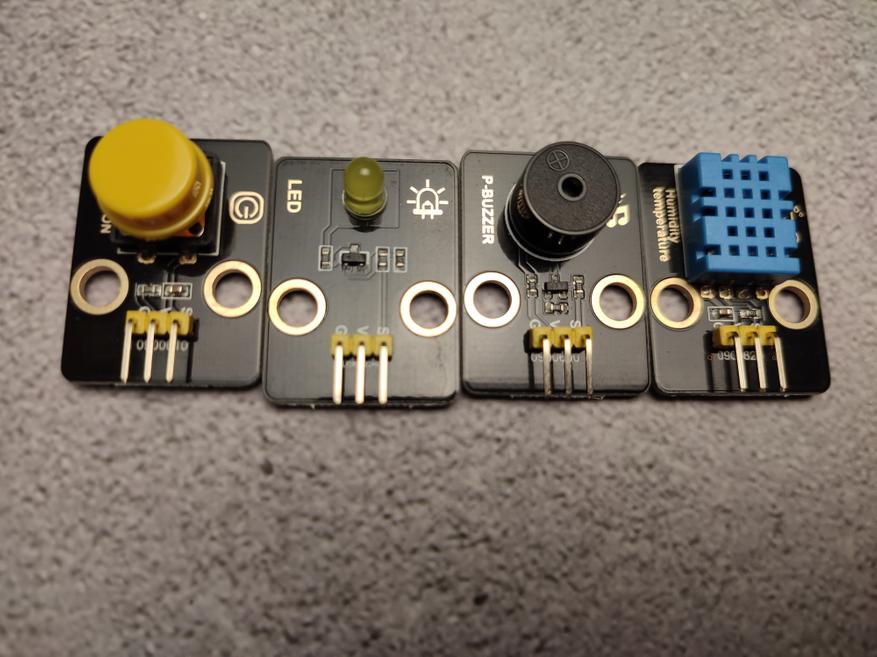

Project 7: Active Buzzer

1.Introduction

Active buzzer is widely used as a sound making element on computer, printer, alarm, electronic toy, telephone, timer and more. It has an inner vibration source. Simply connect it with 5V power supply, it can buzz continuously.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Buzzer*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

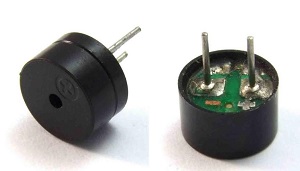

3. Little Knowledge

There are two kinds of buzzer, active buzzer and passive buzzer. In this lesson, we will use Micro:bit to drive an active buzzer. The active buzzer inside has a simple oscillator circuit which can convert constant direct current into a certain frequency pulse signal. Once active buzzer receives a high level, it will produce an audible beep.

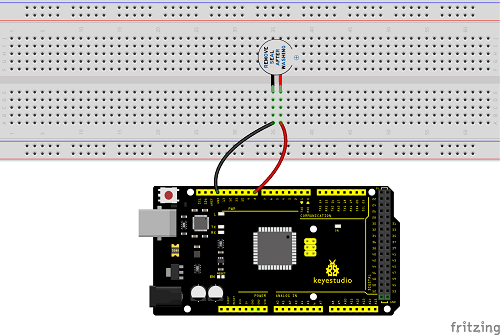

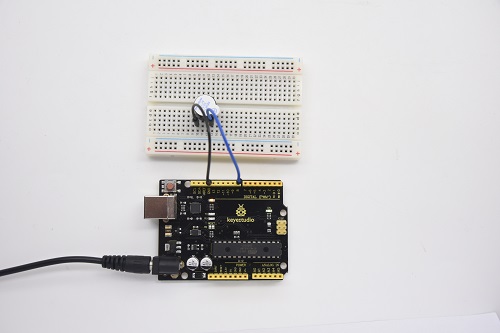

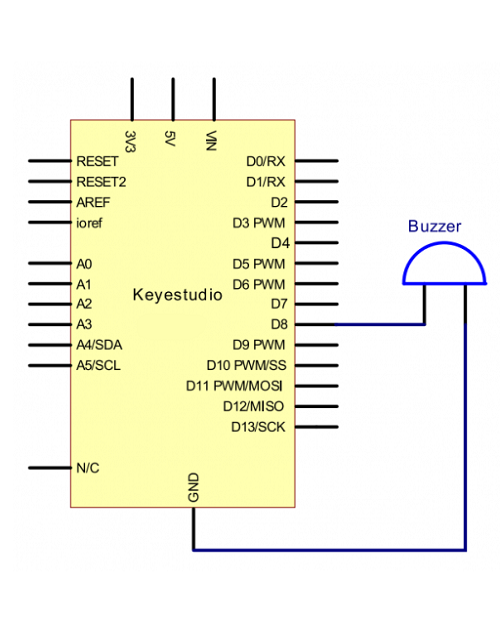

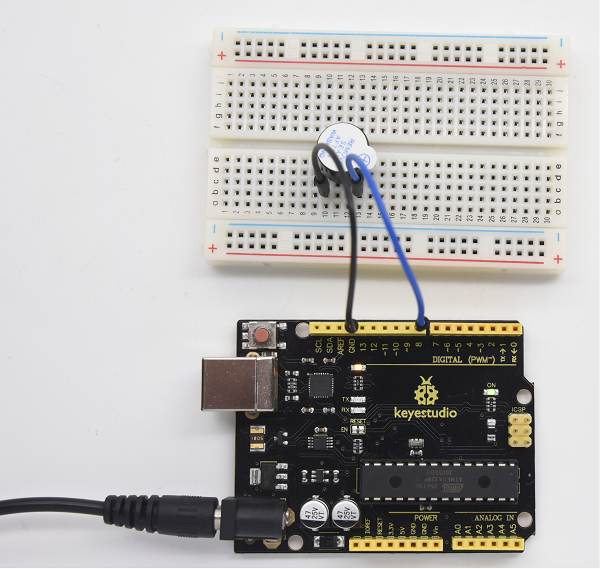

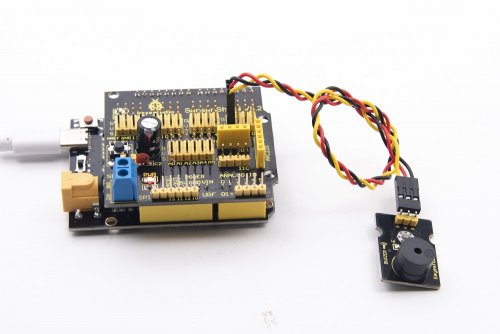

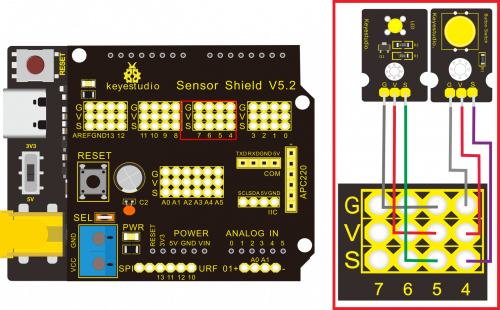

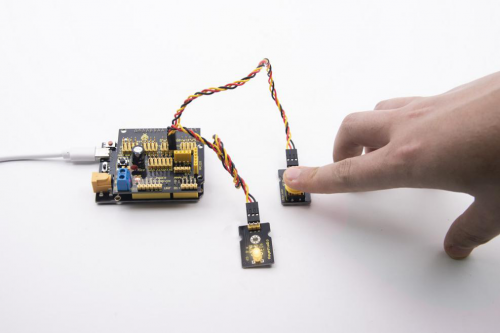

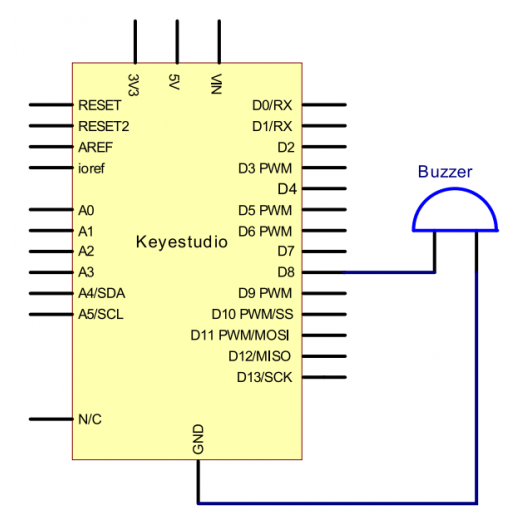

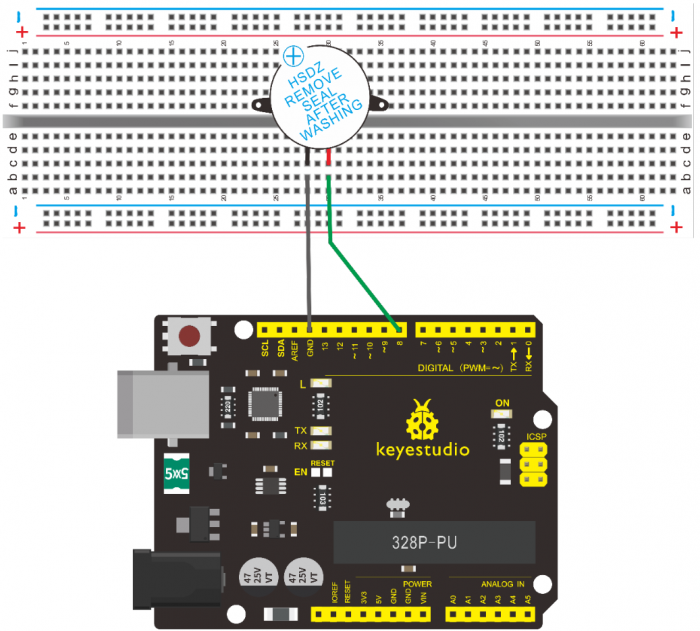

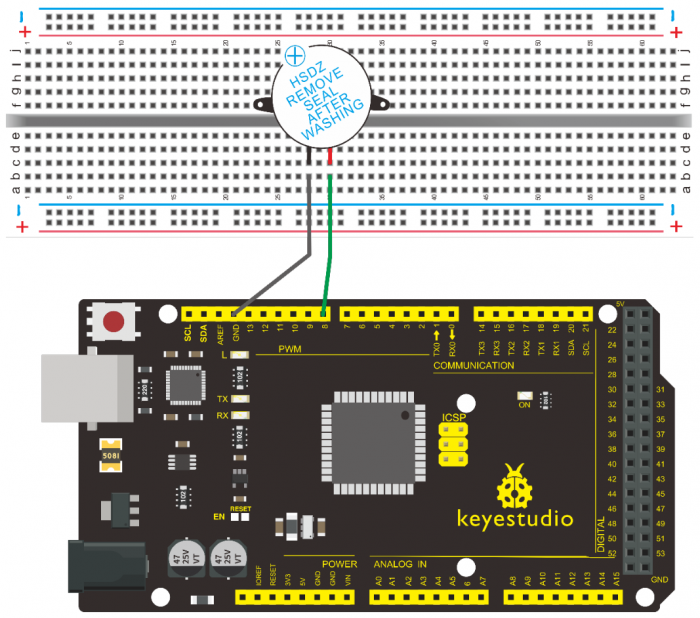

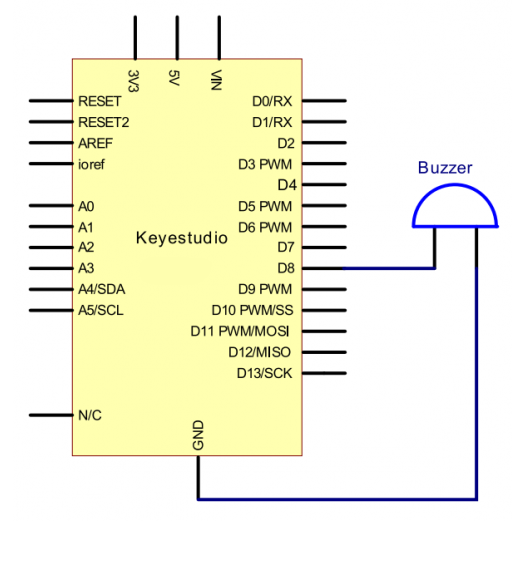

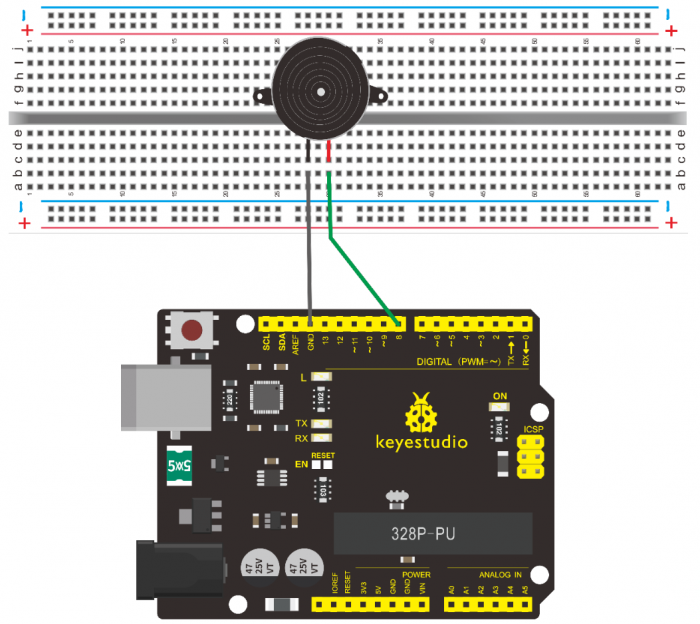

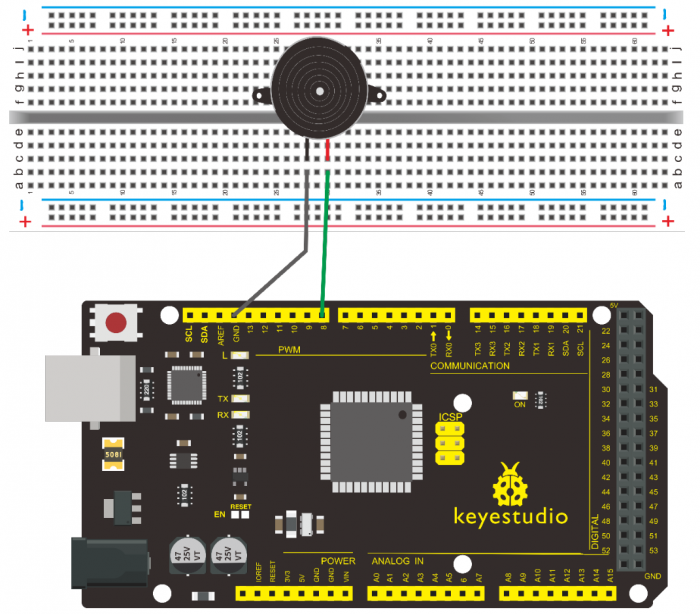

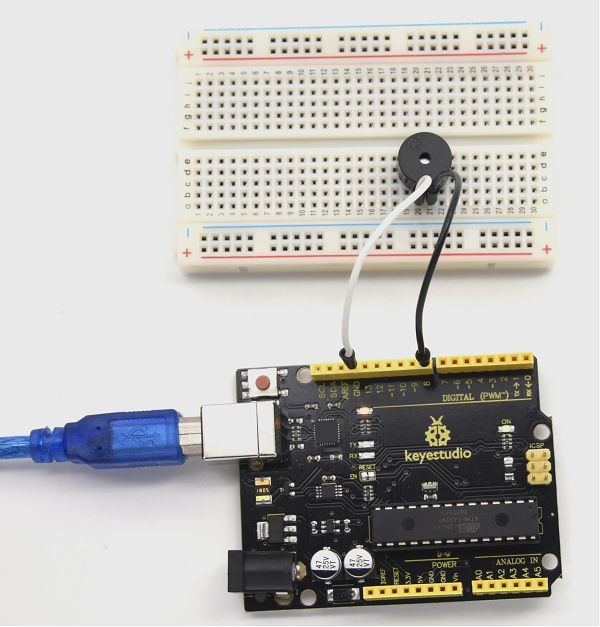

4.Circuit Connection

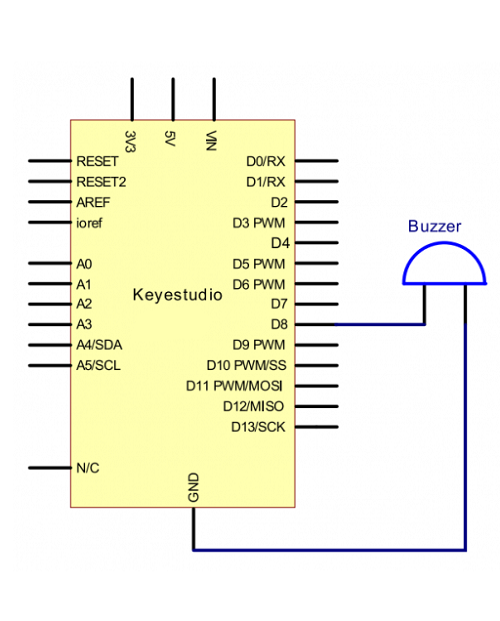

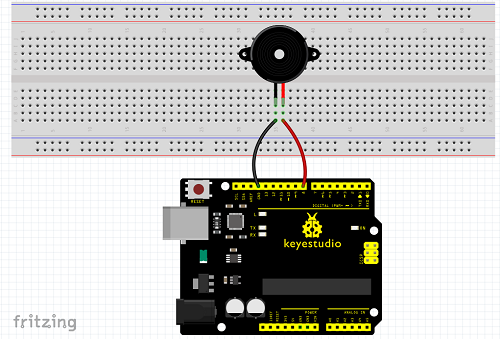

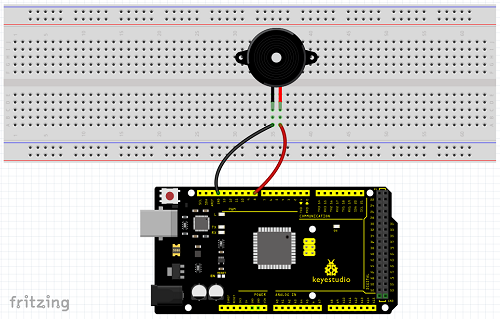

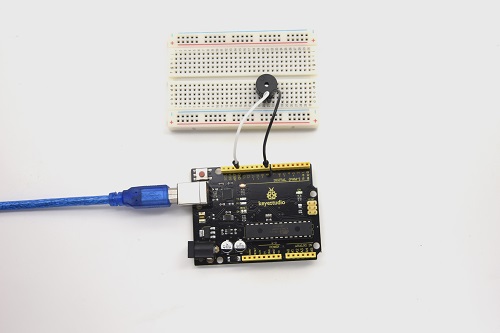

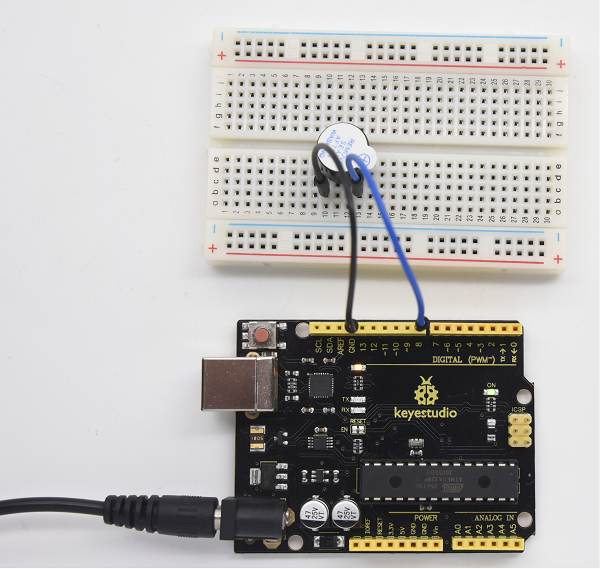

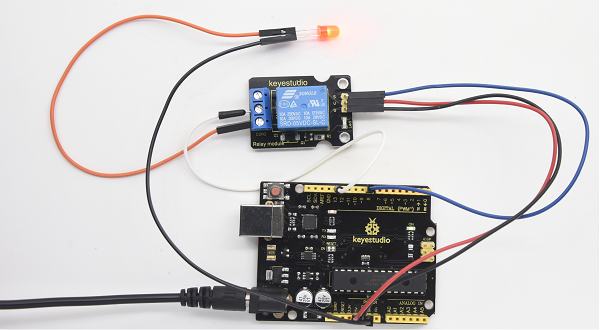

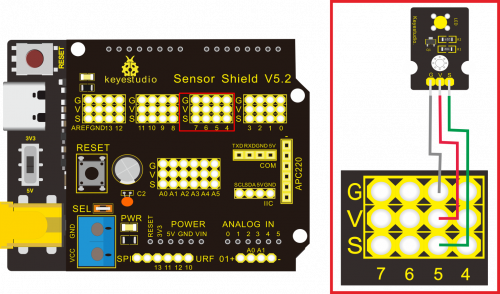

Connection for V4.0

Connection for 2560

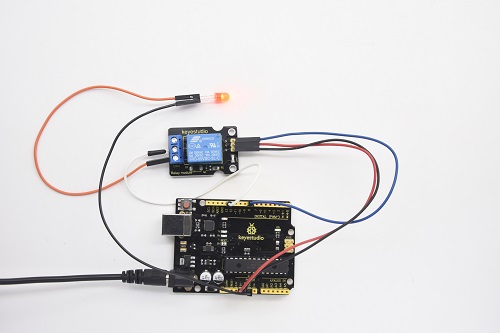

When connecting the circuit, pay attention to the positive and negative poles of the buzzer. In the photo, you can see there are red and black lines. When the circuit is finished, you can begin the programming.

5.Sample Code

Program is simple. You control the buzzer by outputting high/low level.

/*

keyestudio super learning kit

Project 7

Active Buzzer

http//www.keyestudio.com

*/

int buzzer=8;// initialize digital IO pin that controls the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set pin mode as “output”

}

void loop()

{

digitalWrite(buzzer, HIGH); // produce sound

}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading the program, the buzzer experiment is completed. You can see the buzzer is ringing.

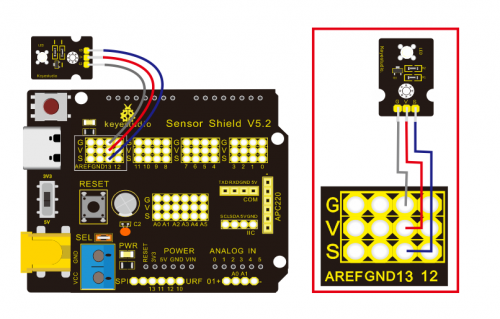

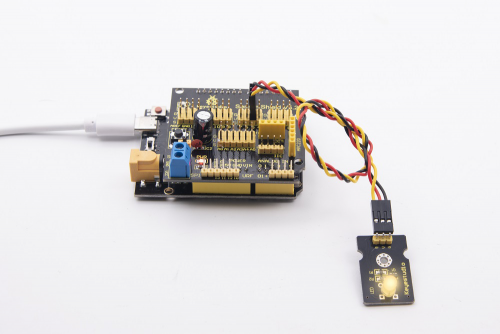

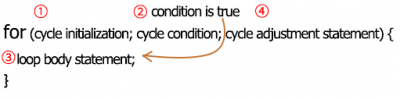

Project 8: Passive Buzzer

1.Introduction

We can use Arduino to make many interactive works. The most commonly used one is acoustic-optic display. All the previous experiment has something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer but not a speaker while buzzer is more simpler and easier to use.

The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequency produces different sound. We can use Arduino to code the melody of a song, which is quite fun and simple.

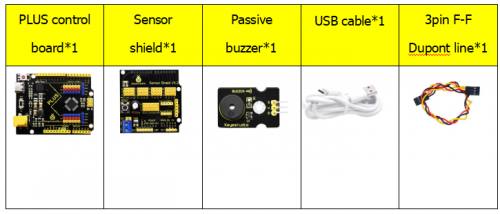

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Passive Buzzer*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

3. Little knowledge

Passive buzzer is an integrated electronic buzzer without vibration source inside. It must be driven by 2K-5K square wave instead of direct current signals. There is little difference between the two buzzers, but when the pins of the two buzzers are placed up, the passive buzzer comes with green circuit board, and the one sealed with vinyl is an active buzzer.

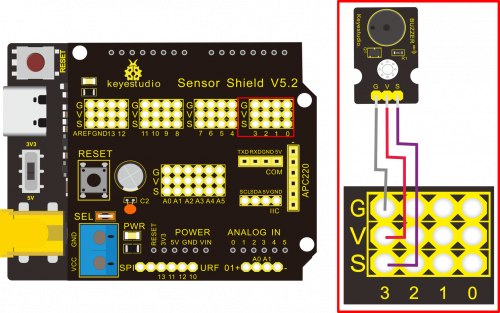

4.Circuit Connection

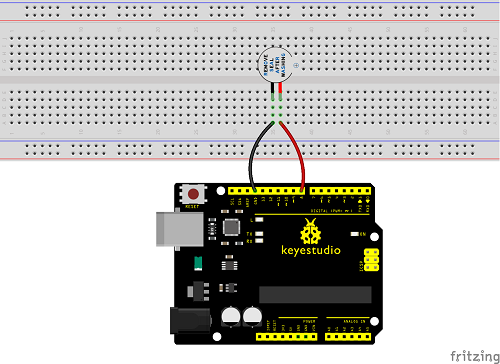

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 8

Passive Buzzer

http//www.keyestudio.com

*/

int buzzer=8;// select digital IO pin for the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output

}

void loop()

{ unsigned char i,j;//define variable

while(1)

{ for(i=0;i<80;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(1);//delay1ms

digitalWrite(buzzer,LOW);//not sound

delay(1);//ms delay

}

for(i=0;i<100;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(2);//2ms delay

digitalWrite(buzzer,LOW);//not sound

delay(2);//2ms delay

}}}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading the program, buzzer experiment is finished, you can hear the buzzer sound.

Project 9: RGB LED

1.Introduction

The RGB color mode is a color standard in the industry. It obtains various colors by changing the three color channels of red (R), green (G), and blue (B) and integrating them. RGB denotes the three colors of red, green and blue.

In this project, we use Arduino to mix these three colors in equal amounts to produce white light.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB Cable * 1

- RGB LED * 1

- Resistor *3

- Breadboard jumper wire*5

3. Little Knowledge

The monitors mostly adopt the RGB color standard, and all the colors on the computer screen are composed of the three colors of red, green and blue mixed in different proportions.

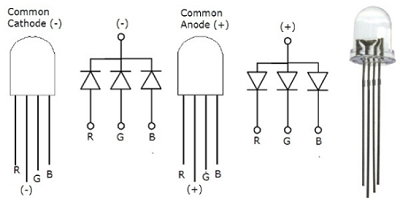

RGB is inclusive of common cathode RGB and common anode RGB.

And we could adjust the LED brightness by PWM

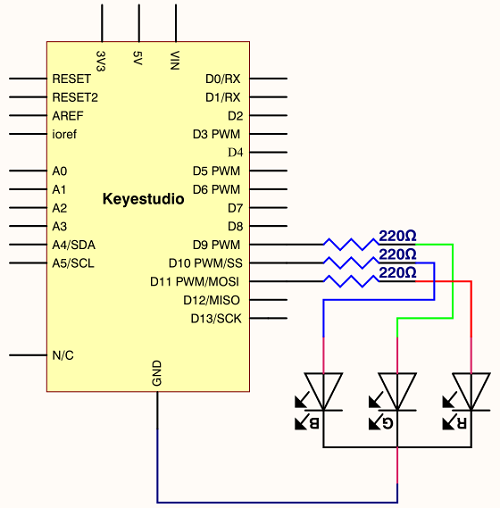

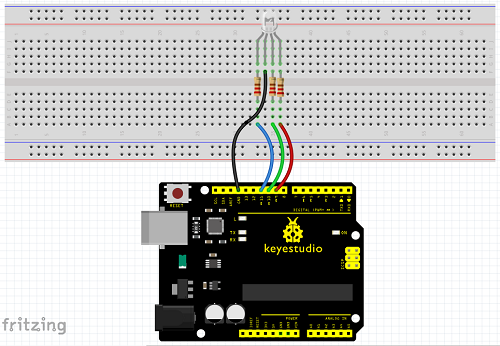

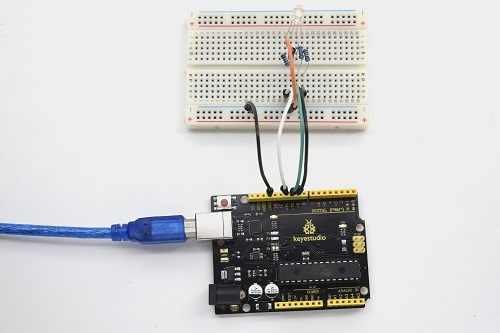

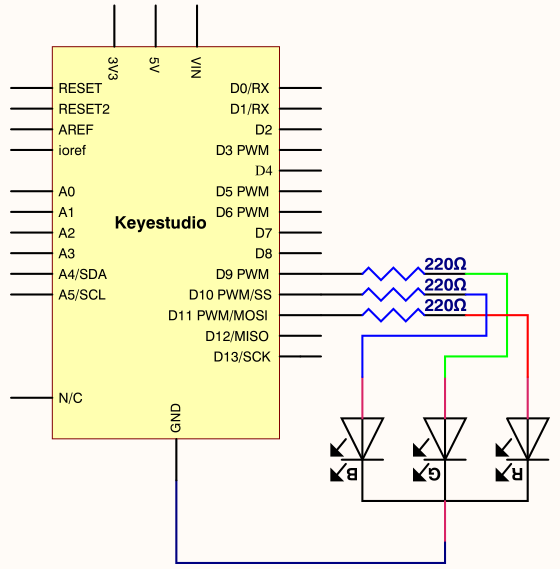

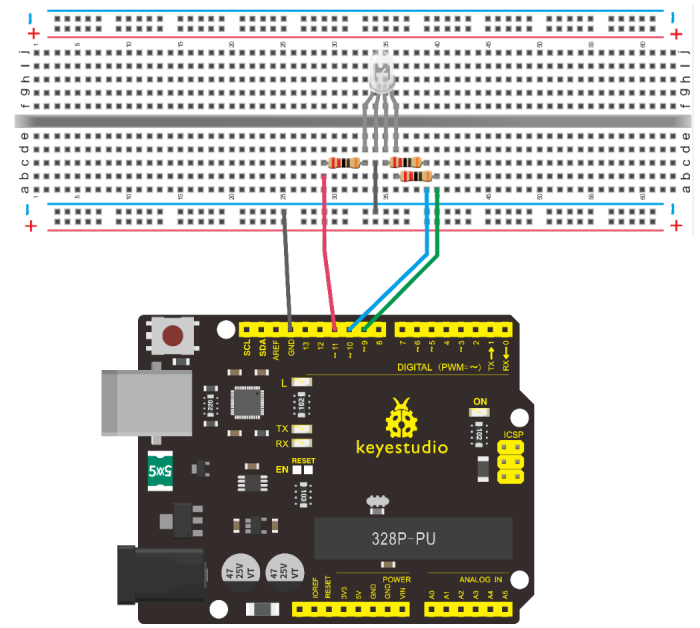

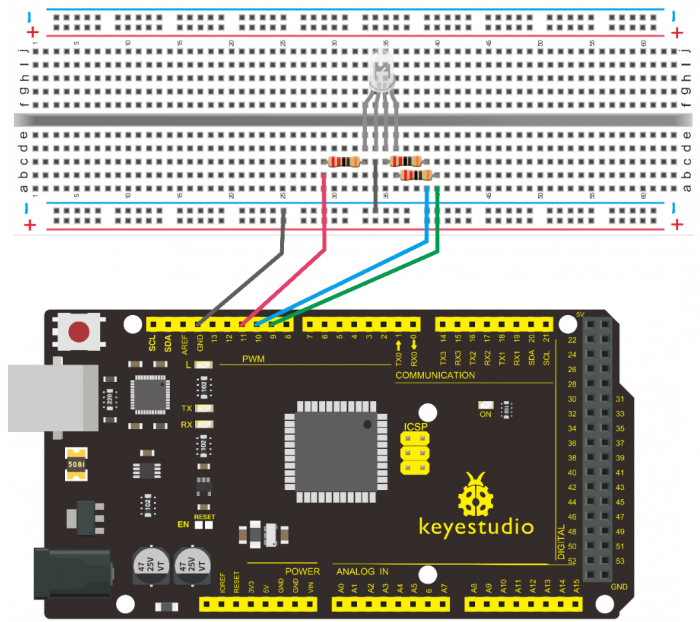

4.Circuit Connection

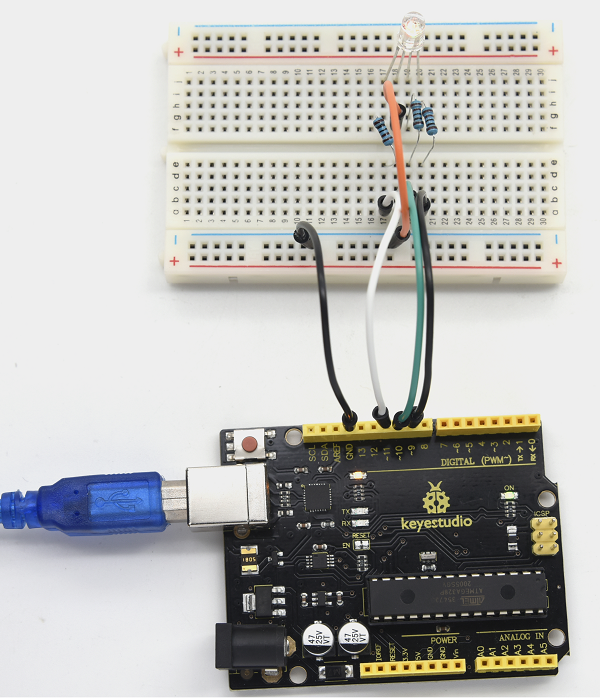

Connection for V4.0

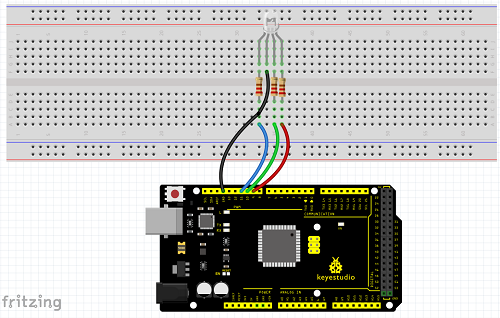

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 9

RGB

http//www.keyestudio.com

*/

int redpin = 11; //select the pin for the red LED

int bluepin =10; // select the pin for the blue LED

int greenpin =9;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

Serial.begin(9600);

}

void loop()

{

for(val=255; val>0; val--)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val<255; val++)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

Serial.println(val, DEC);

}

//////////////////////////////////////////////////////////////////

6.Test Result

Directly copy the above code into arduino IDE, and click upload, wait for a few seconds, you can see a full-color LED.

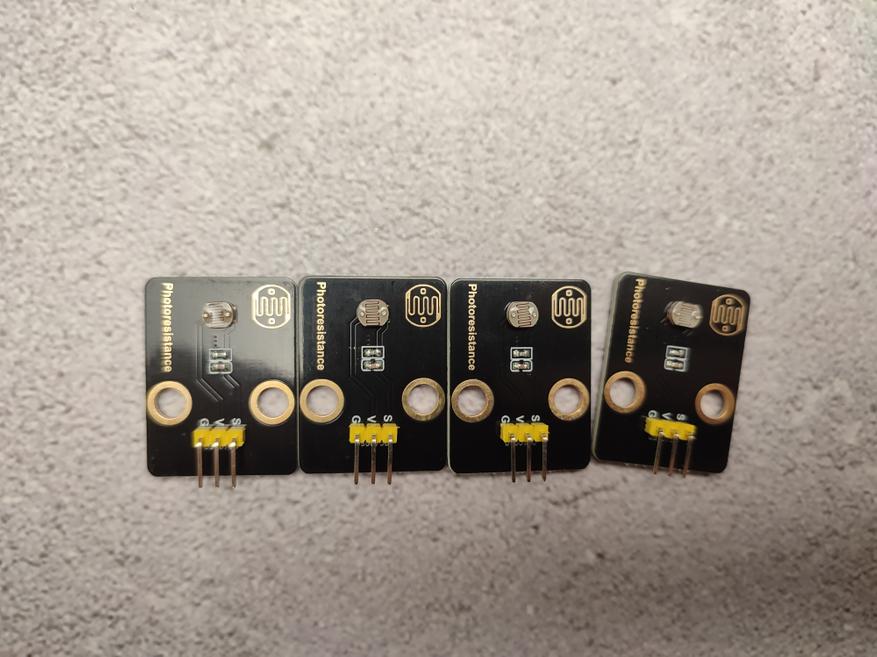

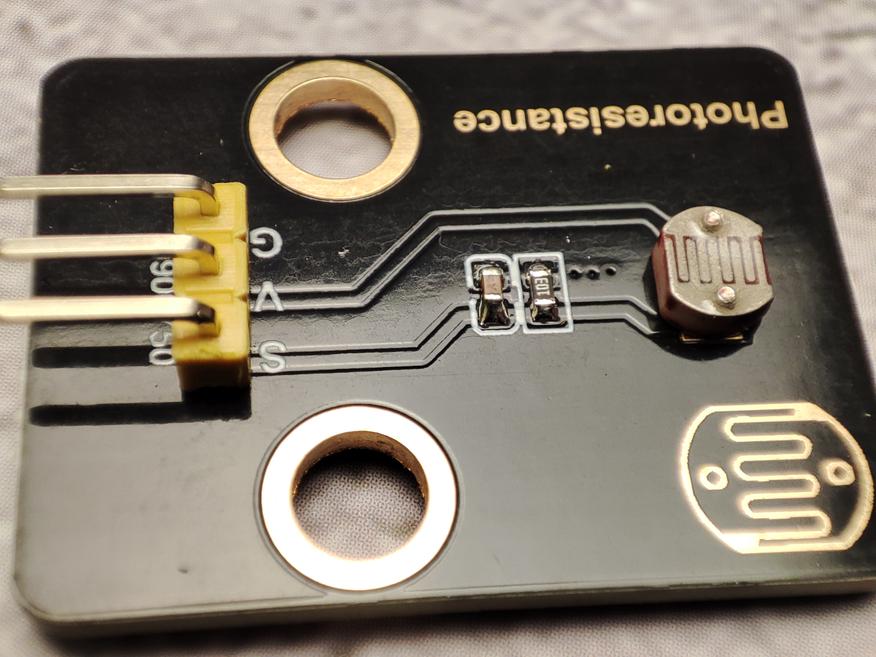

Project 10: Photo Resistor

1.Introduction

After completing all the previous experiments, you may acquire some basic understanding and knowledge about Arduino application. We have introduced digital input and output, analog input and PWM.

Now, let’s begin the learning of sensor applications.

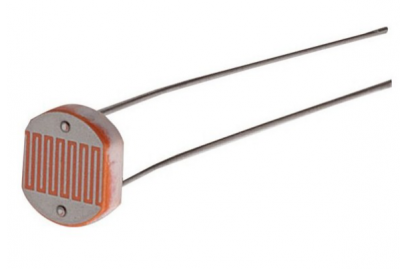

Photo Resistor (Photovaristor) is a resistor whose resistance varies from different incident light strength. It’s based on the photoelectric effect of semiconductor. If the incident light is intense, its resistance reduces; if the incident light is weak, the resistance increases.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Photo Resistor*1

- Red M5 LED*1

- 10KΩ Resistor*1

- 220Ω Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*5

- USB cable*1

3.Little Knowledge

Photovaristor is commonly applied in the measurement of light, light control and photovoltaic conversion (convert the change of light into the change of electricity).

Photo resistor is also being widely applied to various light control circuit, such as light control and adjustment, optical switches, etc.

We will start with a relatively simple experiment regarding to photovaristor application.

Photovaristor is an element that can change its resistance as light strength changes. So need to read the analog value. You can refer to the PWM experiment, replacing the potentiometer with photovaristor. When there is change in light strength, it will make corresponding change on the LED.

4.Circuit Connection

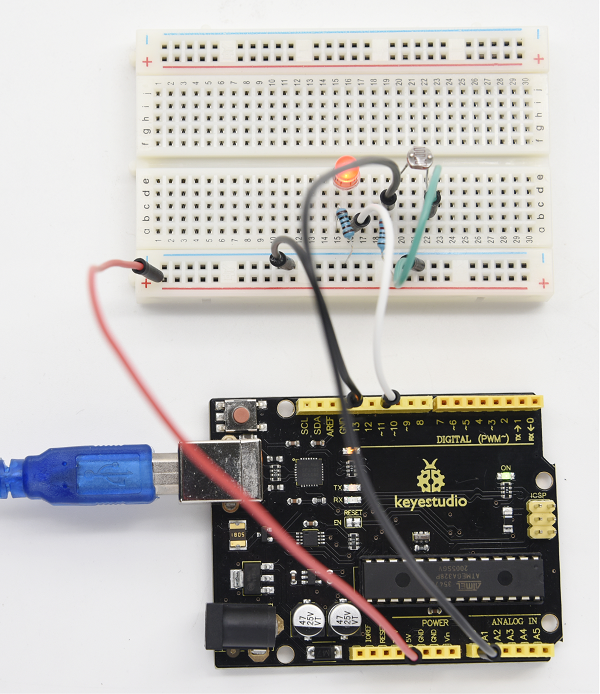

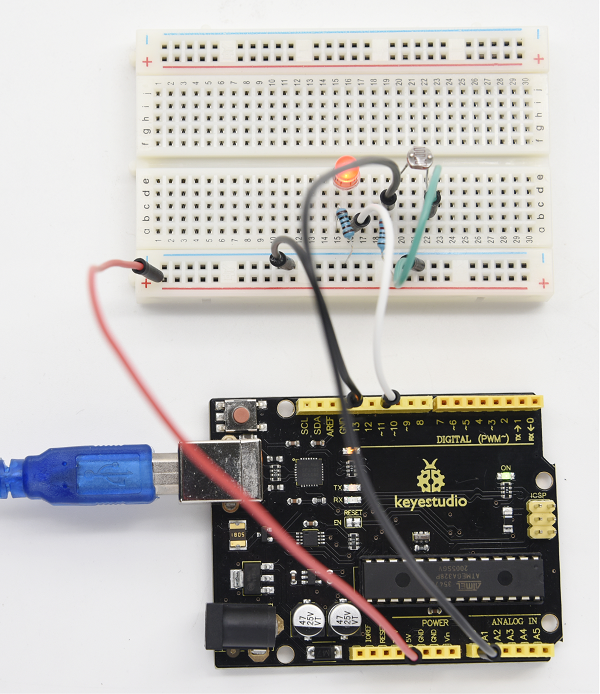

Connection for V4.0

Connection for 2560

5.Sample Code

After wiring, let’s begin the program compiling. The program is similar to the PWM.

For change detail, please refer to the Sample Code below.

/*

keyestudio super learning kit

Project 10

Photo Resistor

http//www.keyestudio.com

*/

int potpin=0;// initialize analog pin 0, connected with photovaristor

int ledpin=11;// initialize digital pin 11,

int val=0;// initialize variable va

void setup()

{

pinMode(ledpin,OUTPUT);// set digital pin 11 as “output”

Serial.begin(9600);// set baud rate at “9600”

}

void loop()

{

val=analogRead(potpin);// read the value of the sensor and assign it to val

Serial.println(val);// display the value of val

analogWrite(ledpin,val/4);// set up brightness(maximum value 255)

delay(10);// wait for 0.01

}

//////////////////////////////////////////////////////////////////

6.Test Result

After downloading the program, you can change the light strength around the photovaristor, and see the corresponding brightness change of the LED.

Photovaristors has various applications in our everyday. You can make other interesting interactive projects based on this one.

Project 11: Flame Sensor

1.Introduction

Flame sensor (infrared receiving triode) is specially used for robots to find the fire source. This sensor is of high sensitivity to flame.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Flame Sensor *1

- Buzzer *1

- 10K Resistor *1

- Breadboard Jumper Wire*6

- USB cable*1

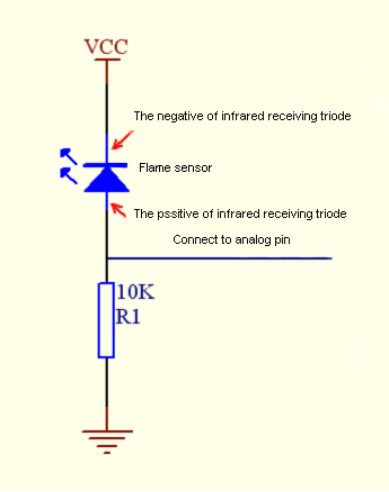

3. Little Knowledge

Flame sensor is based on the principle that infrared ray is highly sensitive to flame. It has an infrared receiving tube specially designed to detect fire, and then to convert the flame brightness into fluctuating level signal. The signals are then input into the central processor and be dealt with accordingly.

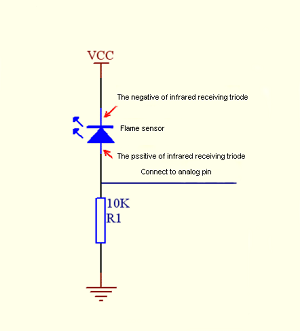

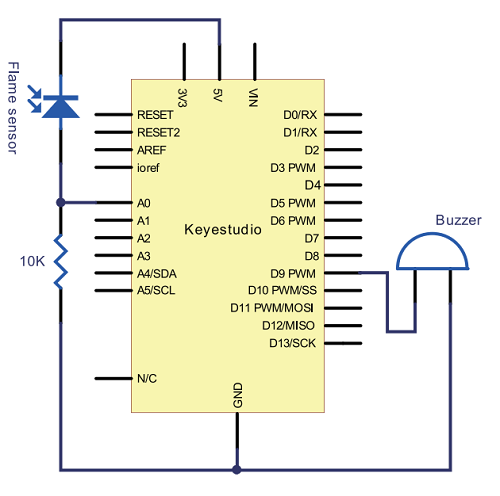

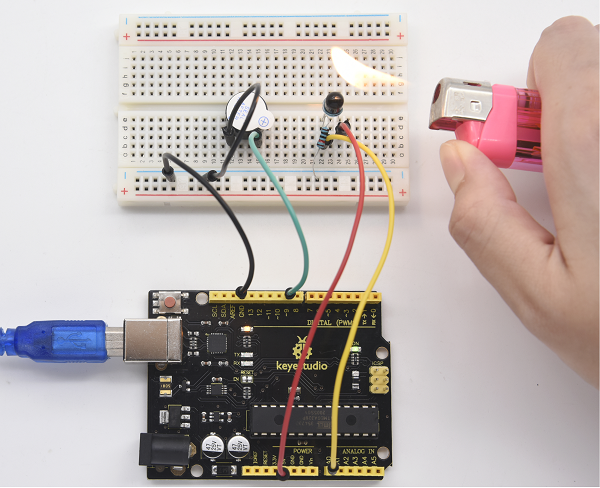

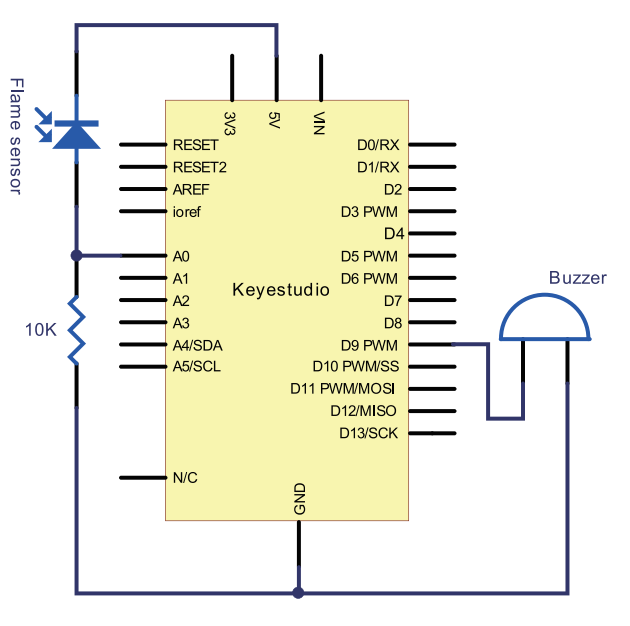

The shorter lead of the receiving triode is for negative, the other one for positive. Connect negative to 5V pin, positive to resistor; connect the other end of the resistor to GND, connect one end of a jumper wire to a clip which is electrically connected to sensor positive, the other end to analog pin. As shown below

4.Experiment Principle

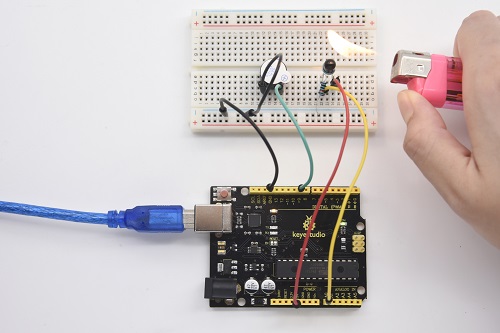

When it’s approaching a fire, the voltage value read from the analog port will differ. If you use a multimeter, you can see that when there is no fire approaching, the voltage it reads is around 0.3V; when there is fire approaching, the voltage it reads is around 1.0V. The nearer the fire is, the higher the voltage is.

So in the beginning of the program, you can initialize voltage value i (no fire value); Then, continuously read the analog voltage value j and obtain difference value k=j-i; compare k with 0.6V (123 in binary) to determine whether there is a fire approaching or not; if yes, the buzzer will buzz.

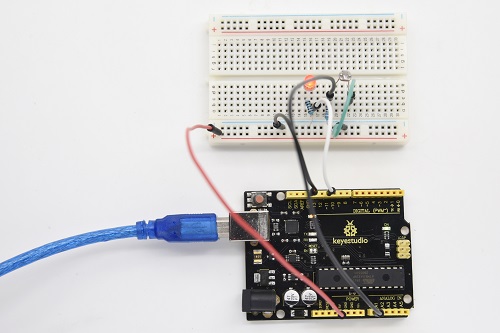

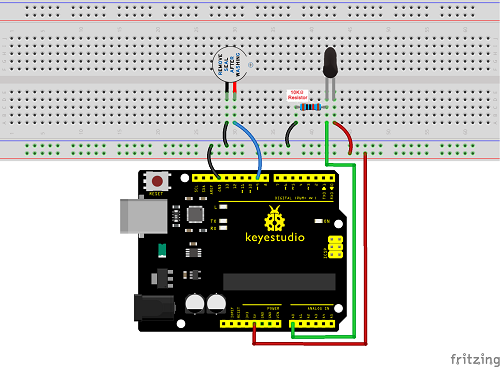

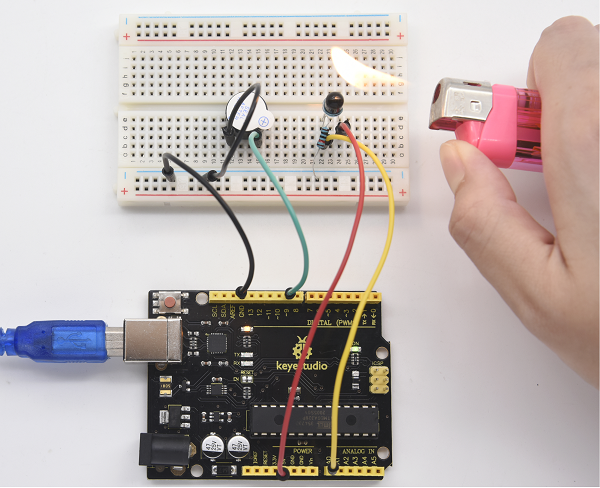

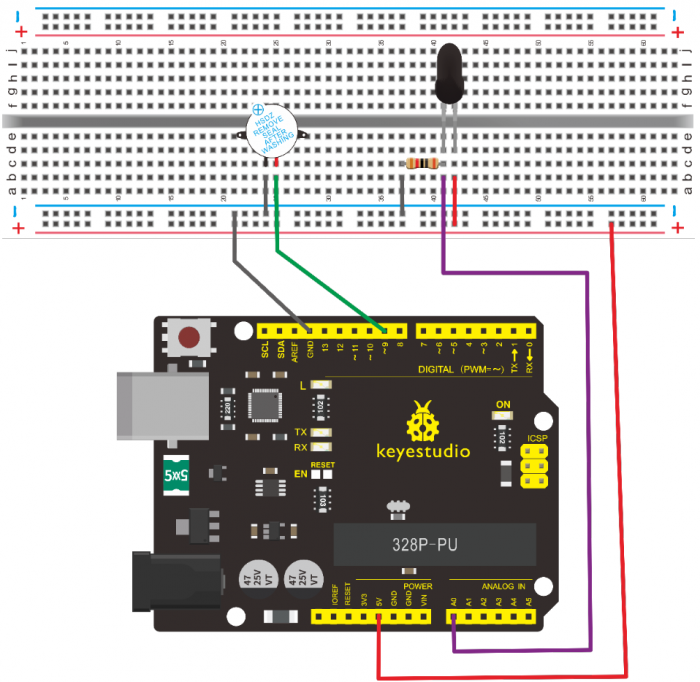

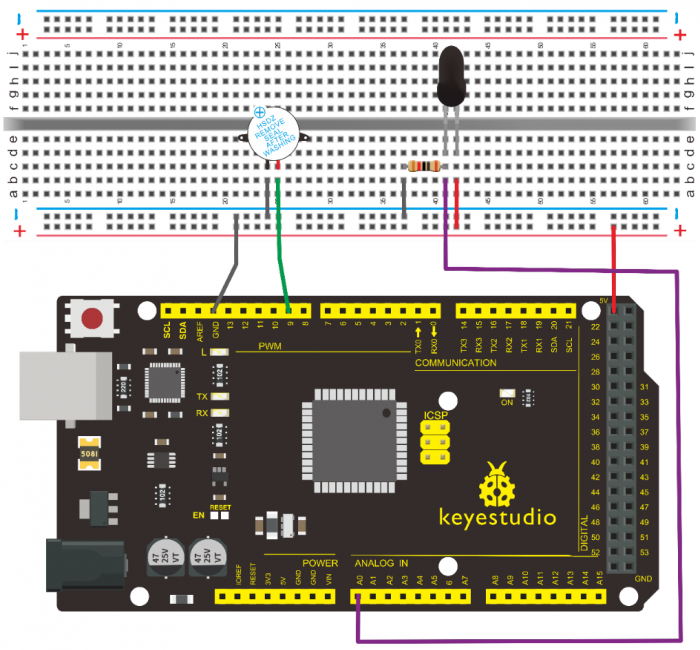

5.Circuit Connection

Connection for V4.0

Connection for MEGA 2560

6.Sample Code

/*

keyestudio super learning kit

Project 11

Flame

http//www.keyestudio.com

*/

int flame=0;// select analog pin 0 for the sensor

int Beep=9;// select digital pin 9 for the buzzer

int val=0;// initialize variable

void setup()

{

pinMode(Beep,OUTPUT);// set LED pin as “output”

pinMode(flame,INPUT);// set buzzer pin as “input”

Serial.begin(9600);// set baud rate at “9600”

}

void loop()

{

val=analogRead(flame);// read the analog value of the sensor

Serial.println(val);// output and display the analog value

if(val>=600)// when the analog value is larger than 600, the buzzer will buzz

{

digitalWrite(Beep,HIGH);

}else

{

digitalWrite(Beep,LOW);

}

delay(500);

}

//////////////////////////////////////////////////////////////////

7.Test Result

This program can simulate an alarm when there is a fire. Everything is normal when there is no fire; when there is fire, the alarm will be set off immediately.

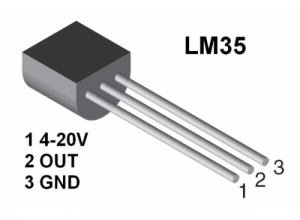

Project 12: LM35 Temperature Sensor

1.Introduction

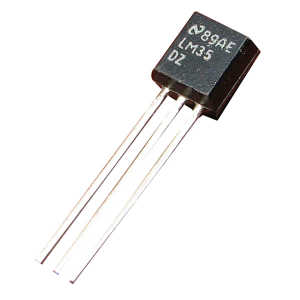

LM35 is a common and easy-to-use temperature sensor. It does not require other hardware. You just need an analog port to make it work. The difficulty lies in compiling the code to convert the analog value it reads into Celsius temperature. In this project, we will guide you how to use LM35 temperature sensor.

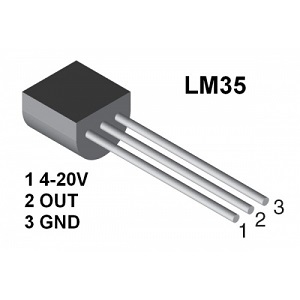

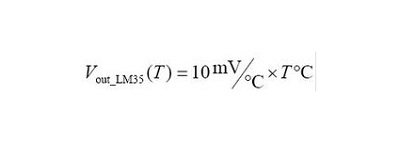

2. Working Principle

LM35 is a widely used temperature sensor with many different package types. At room temperature, it can achieve the accuracy of ±1/4°C without additional calibration processing.

LM35 temperature sensor can produce different voltage by different temperature

When temperature is 0 ℃, it outputs 0V; if increasing 1 ℃, the output voltage will increase 10 mv.

The output temperature is 0℃~100℃, the conversion formula is as follows:

3.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- LM35*1

- Breadboard*1

- Breadboard Jumper Wire*5

- USB cable*

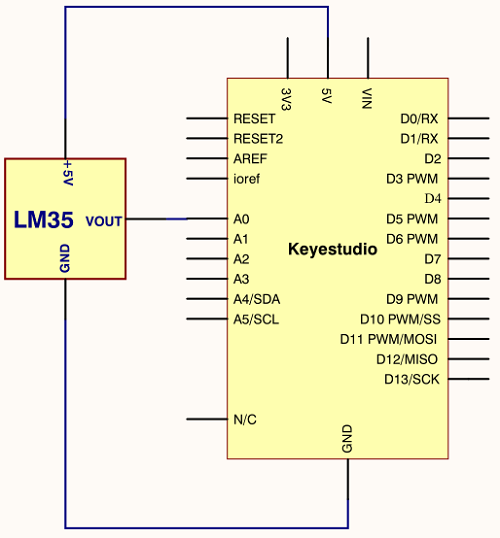

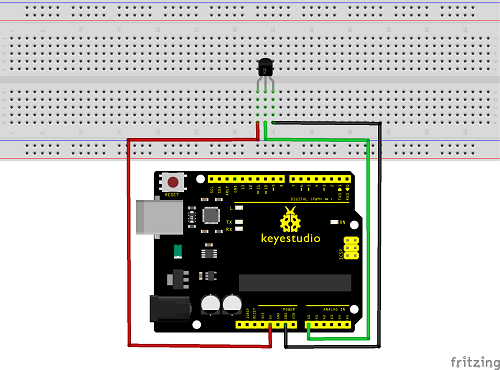

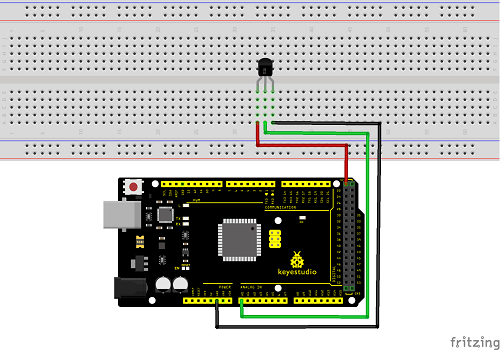

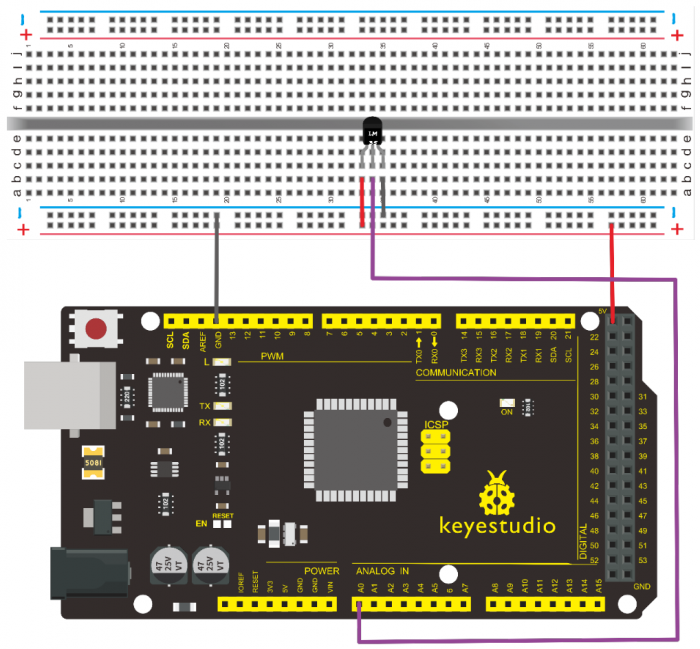

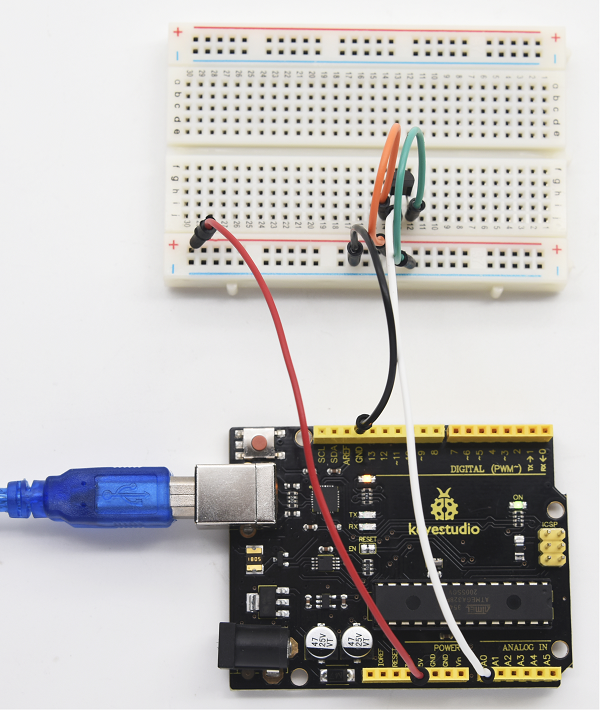

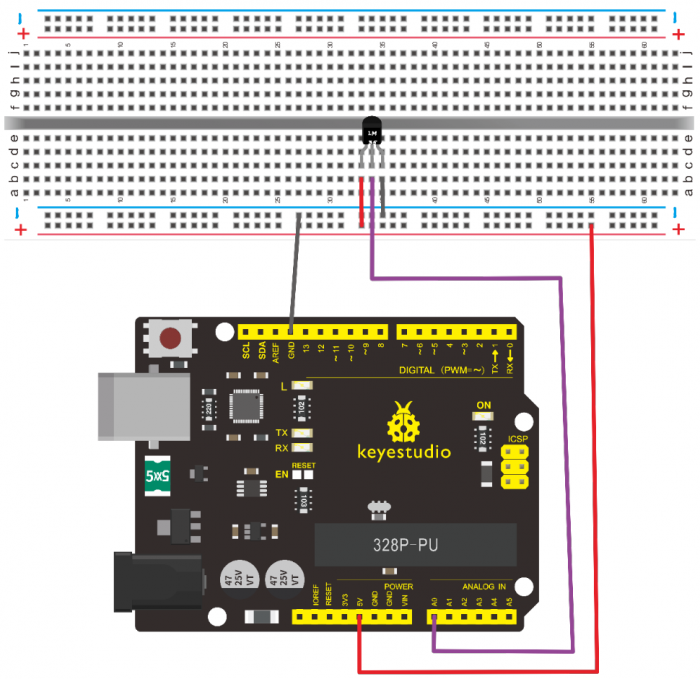

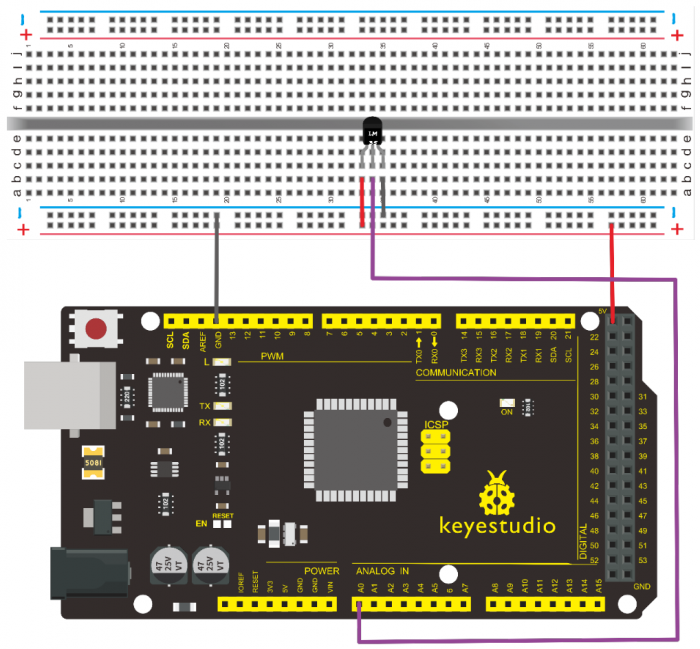

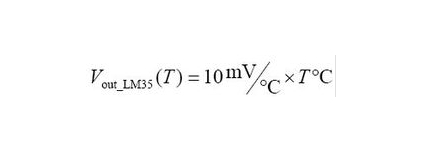

4.Circuit Connection

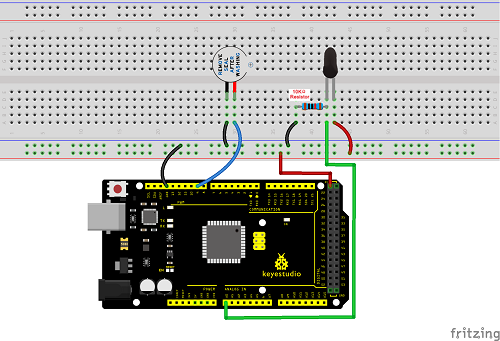

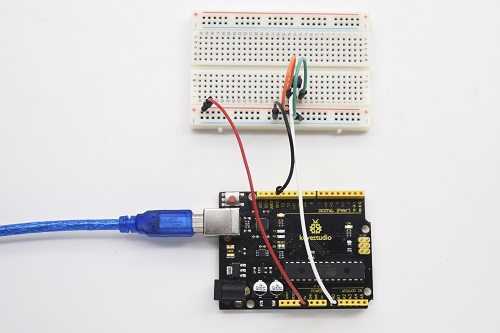

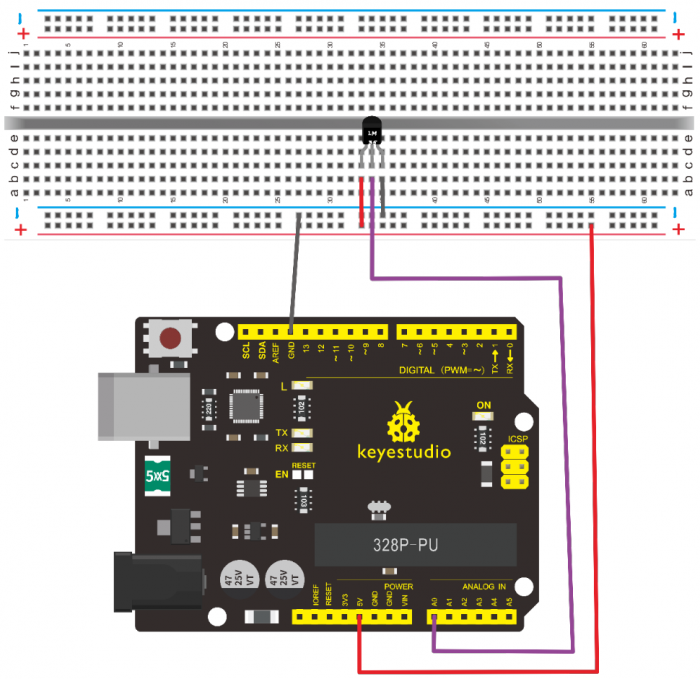

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 12

LM35

http//www.keyestudio.com

*/

int potPin = 0; // initialize analog pin 0 for LM35 temperature sensor

void setup()

{

Serial.begin(9600);// set baud rate at”9600”

}

void loop()

{

int val;// define variable

int dat;// define variable

val=analogRead(0);// read the analog value of the sensor and assign it to val

dat=(125*val)>>8;// temperature calculation formula

Serial.print("Tep");// output and display characters beginning with Tep

Serial.print(dat);// output and display value of dat

Serial.println("C");// display “C” characters

delay(500);// wait for 0.5 second

}

//////////////////////////////////////////////////////////////////

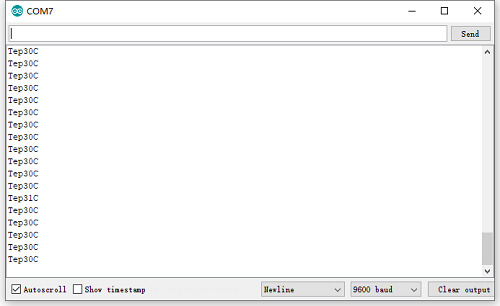

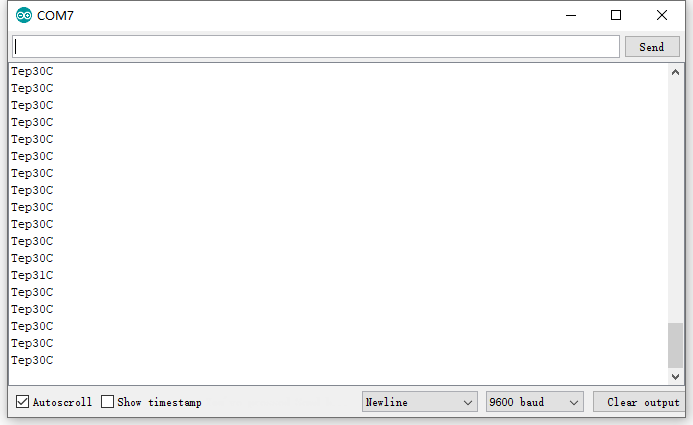

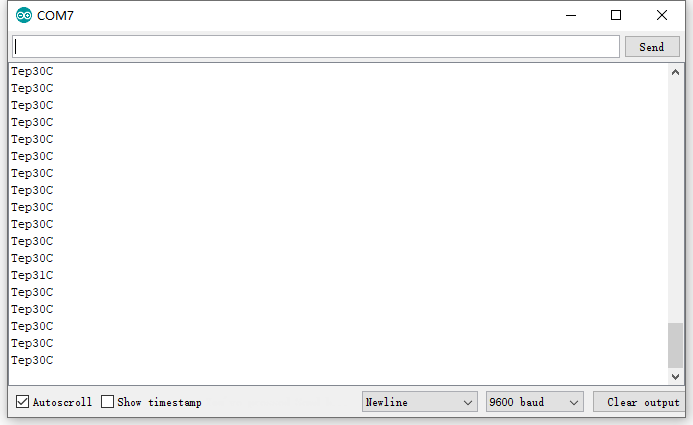

6.Test Result

After uploading the program, you can open the monitoring window to see the current temperature.

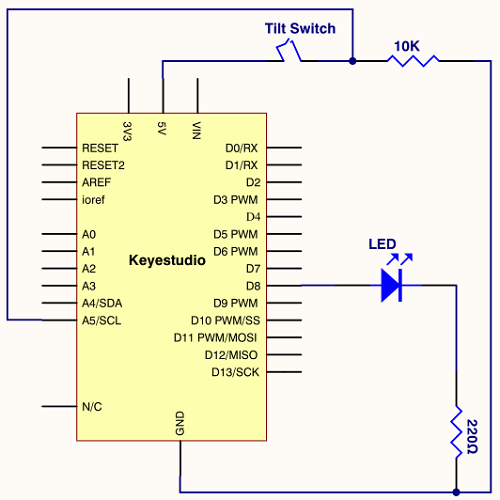

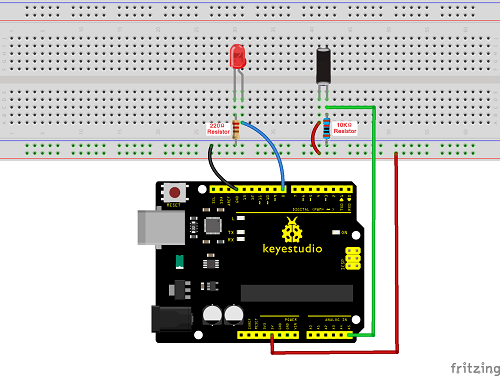

Project 13: Tilt Switch

1.Introduction

This is a ball switch experiment . The ball switch is also dubbed a steel ball switch. It controls the circuit by connecting guide pin with rolling ball. In this project, we control the LED light by reading the state of the ball switch.

2.Working Principle

When one end of the switch is below horizontal position, the switch is on. The voltage of the analog port is about 5V (1023 in binary). The LED will be on.

When the other end of the switch is below horizontal position, the switch is off. The voltage of the analog port is about 0V (0 in binary). The LED will be off.

In the program, we determine whether the switch is on or off according to the voltage value of the analog port, whether it’s above 2.5V (512 in binary) or not.

3.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Ball switch*1

- Led *1

- 220Ω Resistor*1

- 10KΩ resistor*1

- Breadboard Jumper Wire*5

- USB cable*1

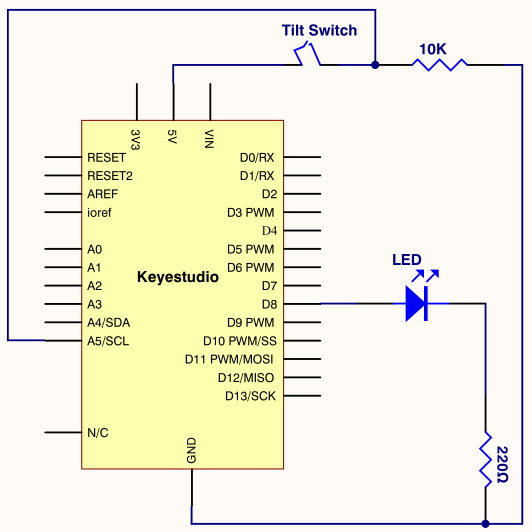

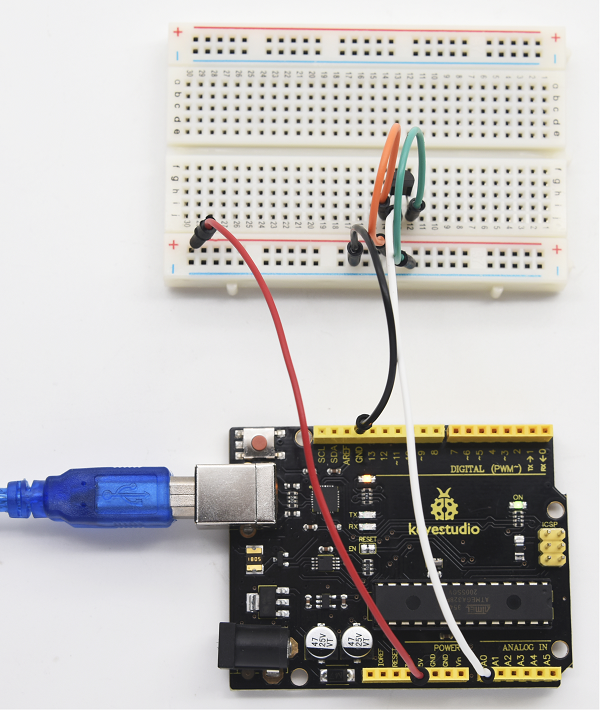

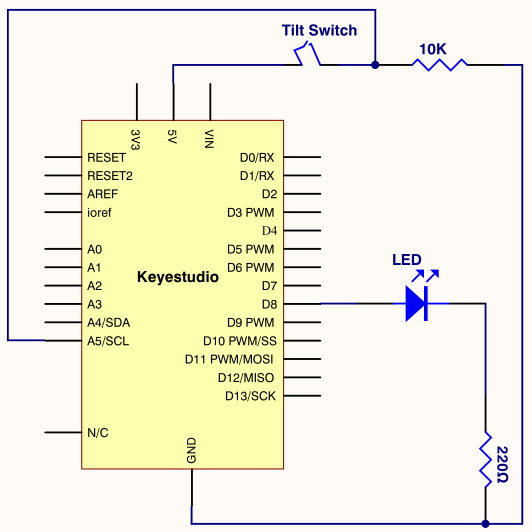

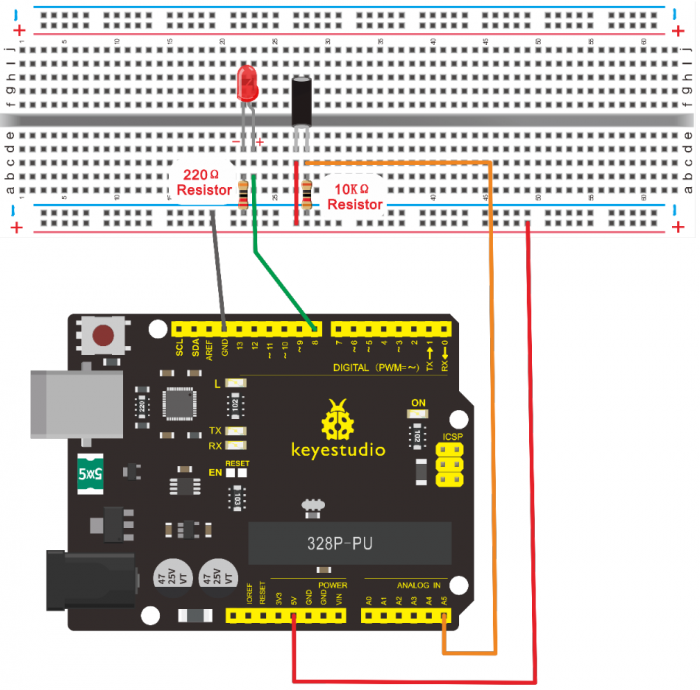

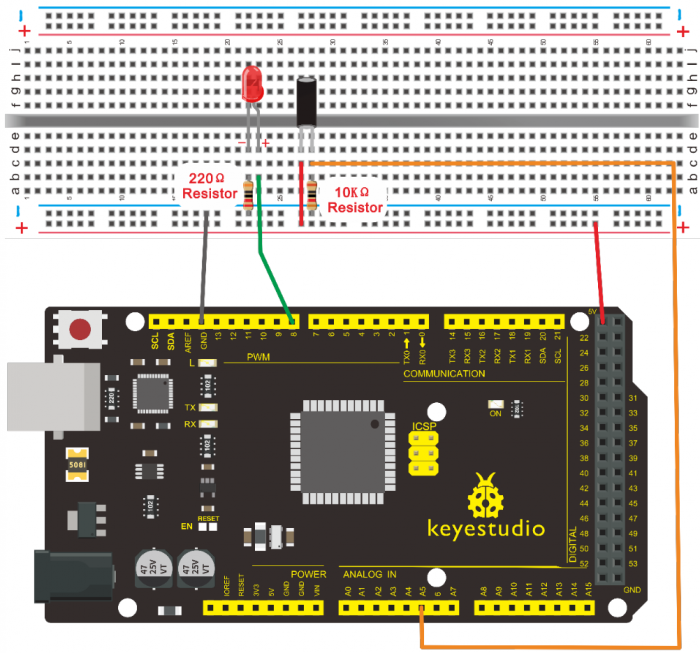

4.Circuit Connection

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 13

Tilt Switch

http//www.keyestudio.com

*/

void setup()

{

pinMode(8,OUTPUT);// set digital pin 8 as “output”

}

void loop()

{

int i;// define variable i

while(1)

{

i=analogRead(5);// read the voltage value of analog pin 5

if(i>512)// if larger that 512(2.5V)

{

digitalWrite(8,LOW);// turn on LED

}

else// otherwise

{

digitalWrite(8,HIGH);// turn off LED

} } }

//////////////////////////////////////////////////////////////////

6.Test Result

Hold the breadboard with your hand. Tilt it to a certain extent, the LED will be on. If there is no tilt, the LED will be off.

The principle of this experiment can be also applied to relay control.

Experiment now is completed. Thank you!

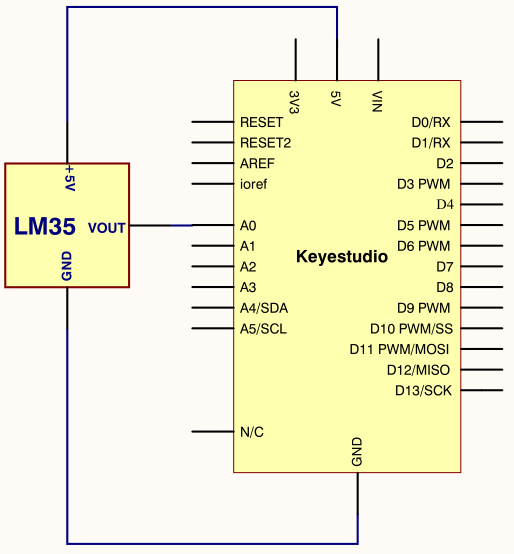

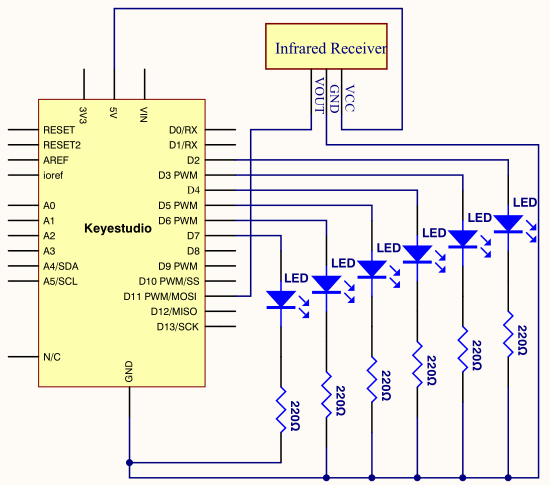

Project 14: IR Remote Control

1.Introduction

What is an infrared receiver?

The signal from the infrared remote controller is a series of binary pulse code. To avoid the other infrared signal interference during the wireless transmission, the signal is pre-modulated at a specific carrier frequency and then send out by an infrared emission diode.

The infrared receiving device needs to filter out other waves and receive signals at that specific frequency and to modulate it back to binary pulse code, known as demodulation.

2.Working Principle

The built-in receiver converts the light signal it received from the sender into feeble electrical signal. The signal will be amplified by the IC amplifier. After automatic gain control, band-pass filtering, demodulation, wave shaping, it returns to the original code. The code is then input to the code identification circuit by the receiver’s signal output pin.

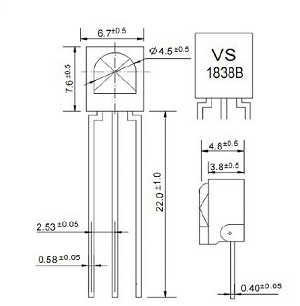

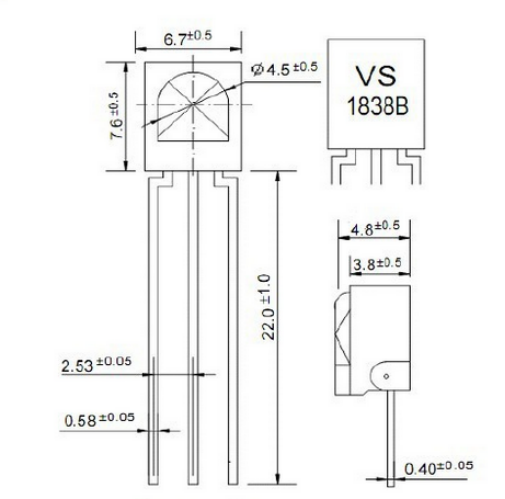

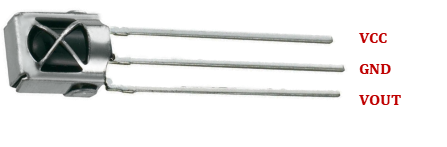

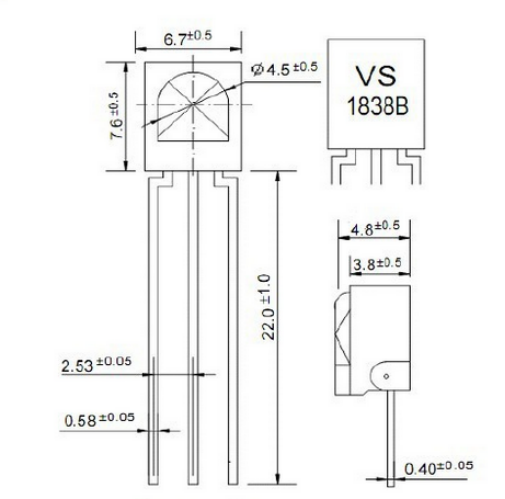

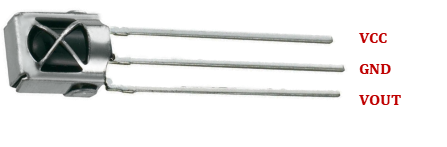

3.Pin and Wiring for Infrared Receiver

Infrared receiver has 3 pins. When you use it, connect VOUT to analog pin, GND to GND, VCC to +5V.

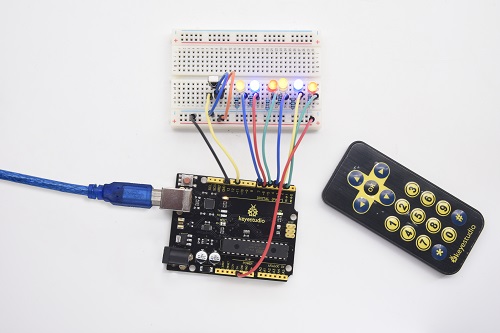

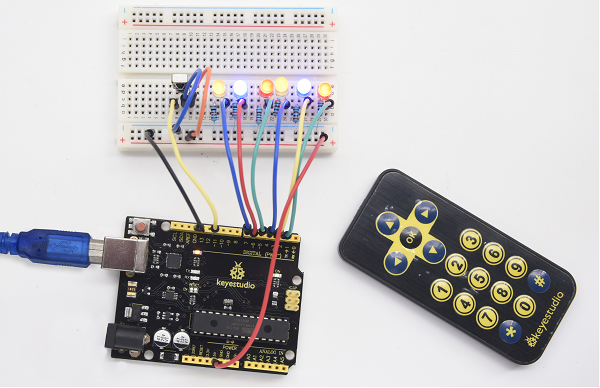

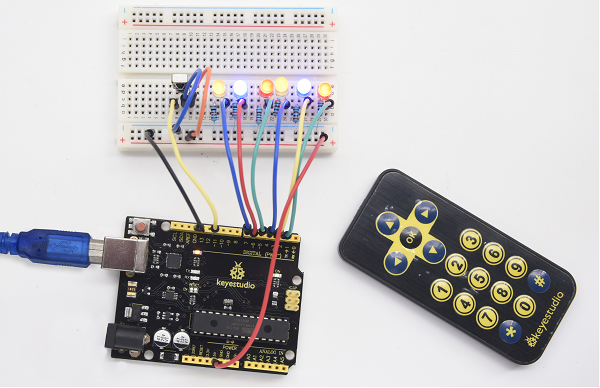

4.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Infrared Remote Controller *1

- Infrared Receiver *1

- LED *6

- 220ΩResistor *6

- Breadboard Wire *11

- USB cable*1

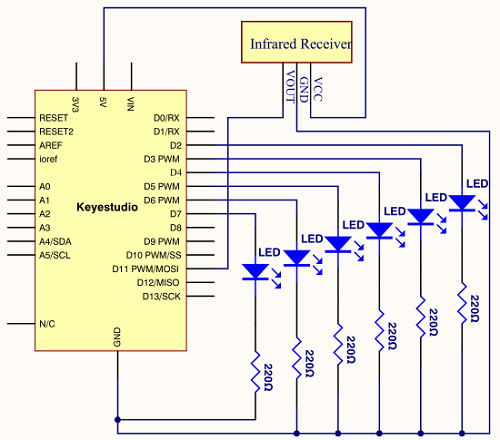

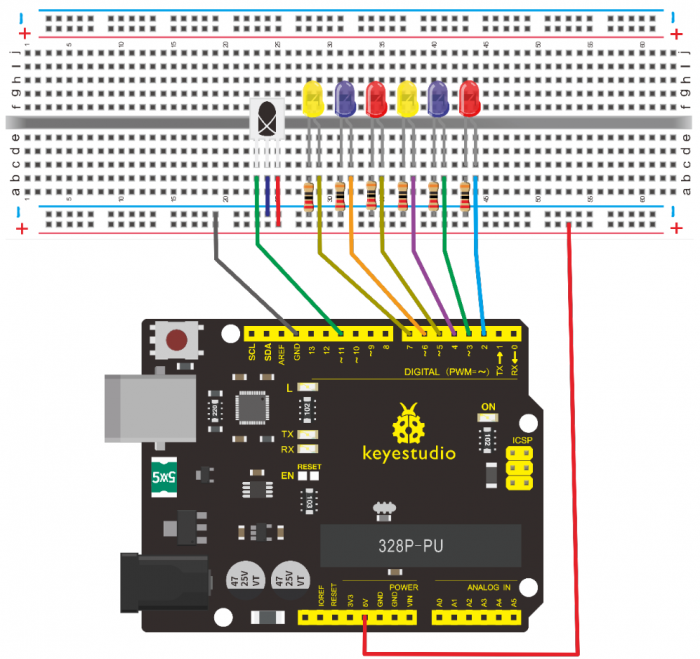

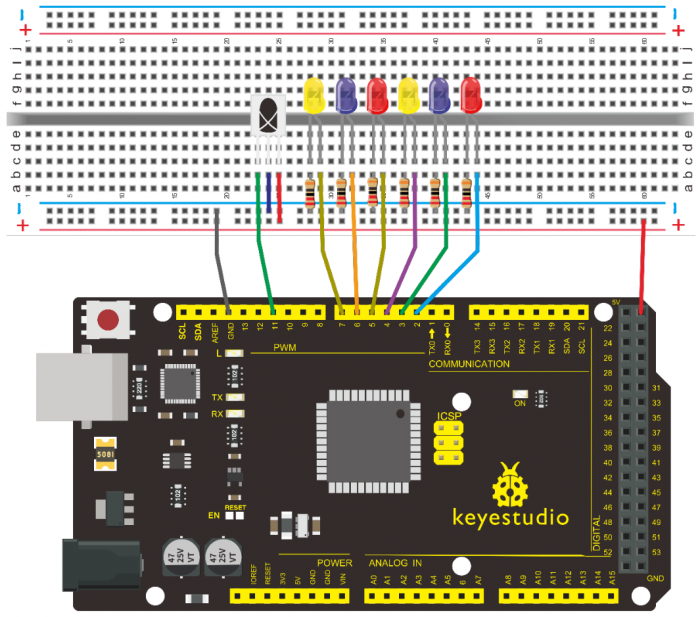

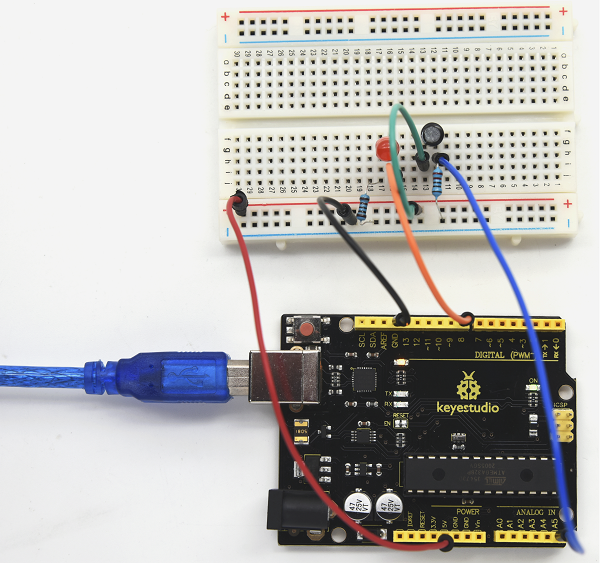

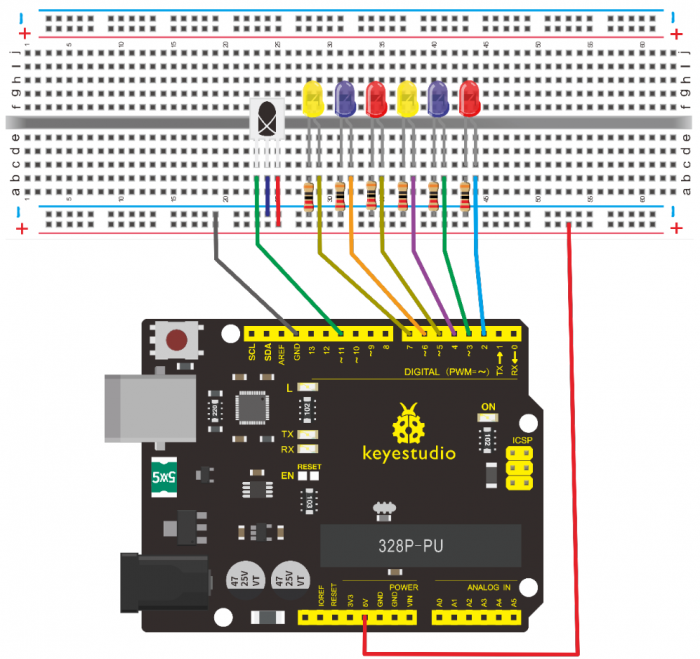

5.Circuit Connection

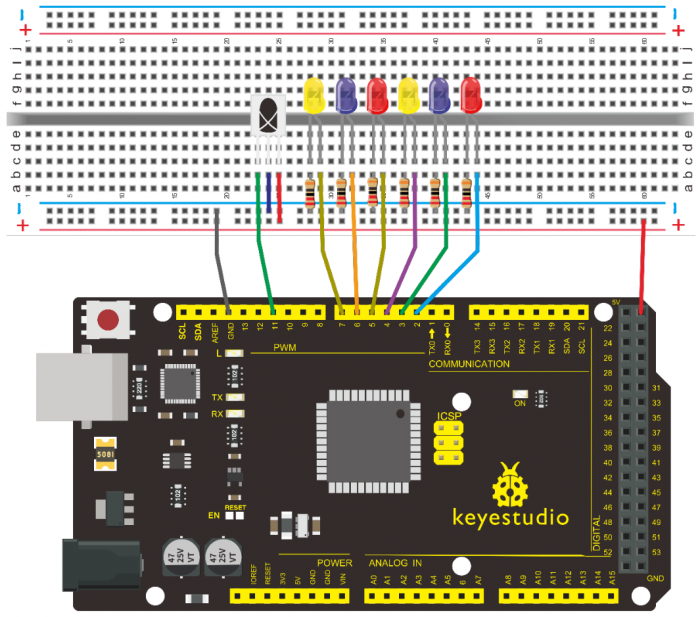

First, connect the controller board; then connect the infrared receiver as the above mentioned, connect VOUT to digital pin 11, connect the LEDs with resistors and connect the resistors to pin 2,3,4,5,6,7.

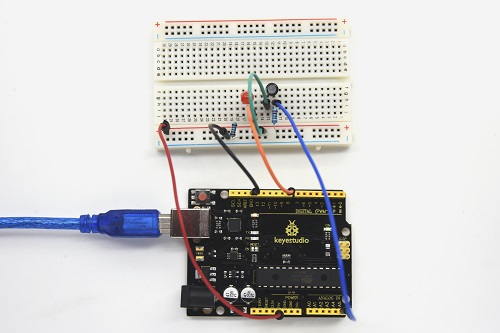

Connection for V4.0

Connection for 2560

6.Experimental Principle

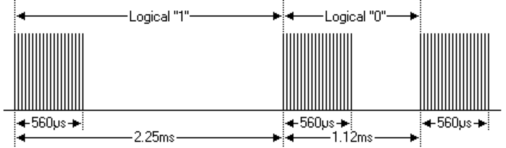

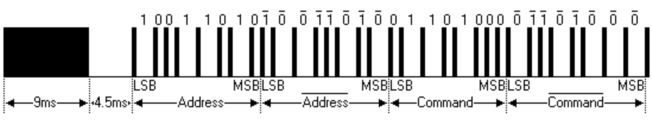

If you want to decode the code from the remote controller, you must first know how it’s coded. The coding method we use here is NEC protocol. Below is a brief introduction.

• NEC protocol

7.Features

- (1)8 bit address and 8 bit command length

- (2) address and command are transmitted twice for reliability

- (3) pulse distance modulation

- (4) carrier frequency of 38 KHZ

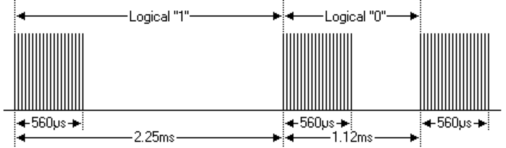

- (5) bit time of 1.125ms or 2.25ms

8.Protocol is as below

• Definition of logical 0 and 1 is as below

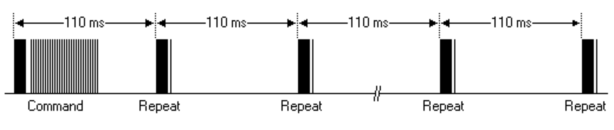

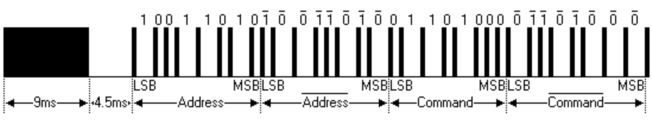

• Pulse transmitted when button is pressed and immediately released

The picture above shows a typical pulse train of the NEC protocol. With this protocol the LSB is transmitted first. In this case Address $59 and Command $16 is transmitted. A message is started by a 9ms AGC burst, which was used to set the gain of the earlier IR receivers. This AGC burst is then followed by a 4.5ms space, which is then followed by the address and command. Address and Command are transmitted twice. The second time all bits are inverted and can be used for verification of the received message. The total transmission time is constant because every bit is repeated with its inverted length. If you are not interested in this reliability, you can ignore the inverted values, or you can expend the Address and Command to 16 bits each!

• Pulse transmitted when button is pressed and released after a period of time

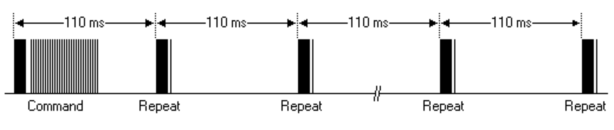

A command is transmitted only once, even when the key on the remote

control remains pressed. Every 110ms a repeat code is transmitted for as long as the key remains down. This repeat code is simply a 9ms AGC pulse followed by a 2.25ms space and a 560µs burst.

• Repeat pulse

Note when the pulse enters the integrated receiver, there will be decoding, signal amplifying and wave shaping process. So you need to make sure the level of the output is just the opposite from that of the signal sending end.

That is when there is no infrared signal, the output end is in high level; when there is infrared signal, the output end is in low level. You can see the pulse of the receiving end in the oscilloscope. Try to better understand the program based on what you see.

9.Sample Code

/*

keyestudio super learning kit

Project 14

Remote

http//www.keyestudio.com

*/

#include <IRremote.h>

int RECV_PIN = 11;

int LED1 = 2;

int LED2 = 3;

int LED3 = 4;

int LED4 = 5;

int LED5 = 6;

int LED6 = 7;

long on1 = 0x00FF6897;

long off1 = 0x00FF9867;

long on2 = 0x00FFB04F;

long off2 = 0x00FF30CF;

long on3 = 0x00FF18E7;

long off3 = 0x00FF7A85;

long on4 = 0x00FF10EF;

long off4 = 0x00FF38C7;

long on5 = 0x00FF5AA5;

long off5 = 0x00FF42BD;

long on6 = 0x00FF4AB5;

long off6 = 0x00FF52AD;

IRrecv irrecv(RECV_PIN);

decode_results results;

// Dumps out the decode_results structure.

// Call this after IRrecv::decode()

// void * to work around compiler issue

//void dump(void *v) {

// decode_results *results = (decode_results *)v

void dump(decode_results *results) {

int count = results->rawlen;

if (results->decode_type == UNKNOWN)

{

Serial.println("Could not decode message");

}

else

{

if (results->decode_type == NEC)

{

Serial.print("Decoded NEC: ");

}

else if (results->decode_type == SONY)

{

Serial.print("Decoded SONY: ");

}

else if (results->decode_type == RC5)

{

Serial.print("Decoded RC5: ");

}

else if (results->decode_type == RC6)

{

Serial.print("Decoded RC6: ");

}

Serial.print(results->value, HEX);

Serial.print(" (");

Serial.print(results->bits, DEC);

Serial.println(" bits)");

}

Serial.print("Raw (");

Serial.print(count, DEC);

Serial.print("): ");

for (int i = 0; i < count; i++)

{

if ((i % 2) == 1) {

Serial.print(results->rawbuf[i]*USECPERTICK, DEC);

}

else

{

Serial.print(-(int)results->rawbuf[i]*USECPERTICK, DEC);

}

Serial.print(" ");

}

Serial.println("");

}

void setup()

{

pinMode(RECV_PIN, INPUT);

pinMode(LED1, OUTPUT);

pinMode(LED2, OUTPUT);

pinMode(LED3, OUTPUT);

pinMode(LED4, OUTPUT);

pinMode(LED5, OUTPUT);

pinMode(LED6, OUTPUT);

pinMode(13, OUTPUT);

Serial.begin(9600);

irrecv.enableIRIn(); // Start the receiver

}

int on = 0;

unsigned long last = millis();

void loop()

{

if (irrecv.decode(&results))

{

// If it's been at least 1/4 second since the last

// IR received, toggle the relay

if (millis() - last > 250)

{

on = !on;

// digitalWrite(8, on ? HIGH : LOW);

digitalWrite(13, on ? HIGH : LOW);

dump(&results);

}

if (results.value == on1 )

digitalWrite(LED1, HIGH);

if (results.value == off1 )

digitalWrite(LED1, LOW);

if (results.value == on2 )

digitalWrite(LED2, HIGH);

if (results.value == off2 )

digitalWrite(LED2, LOW);

if (results.value == on3 )

digitalWrite(LED3, HIGH);

if (results.value == off3 )

digitalWrite(LED3, LOW);

if (results.value == on4 )

digitalWrite(LED4, HIGH);

if (results.value == off4 )

digitalWrite(LED4, LOW);

if (results.value == on5 )

digitalWrite(LED5, HIGH);

if (results.value == off5 )

digitalWrite(LED5, LOW);

if (results.value == on6 )

digitalWrite(LED6, HIGH);

if (results.value == off6 )

digitalWrite(LED6, LOW);

last = millis();

irrecv.resume(); // Receive the next value

}

}

//////////////////////////////////////////////////////////////////

Note: add IRremote folder into installation directory \Arduino\compiler libraries, or you will fail to compile it.

Infrared remote library https//github.com/shirriff/Arduino-IRremote

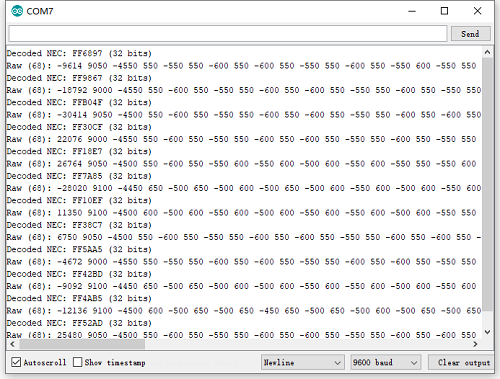

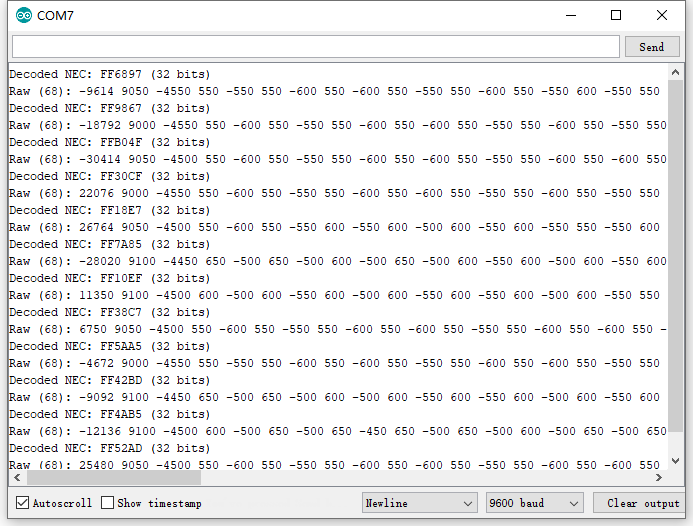

10.Test Result

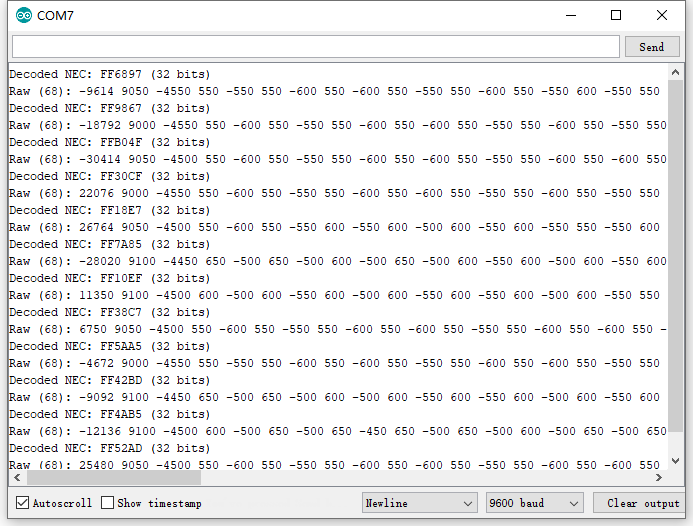

Decode the coded pulse signal emitted by the remote controller, then execute corresponding action according to the results of the decoding. In this way, you will be able to control your device with remote controller.

Done uploading, open the serial monitor, you can see the result as below.

Project 15: Analog Value Reading

1.Introduction

In this experiment, we will begin the study of analog I/O interfaces. On an Arduino, there are 6 analog interfaces numbered from A0 to A5. Next, let’s begin our project. Potentiometer used here is a typical output component of analog value that is familiar to us.

2.Hardware Required

V4.0 Board or MEGA 2650 Board*1

Potentiometer *1

Breadboard*1

Breadboard Jumper Wire*3

USB cable*1

3.Potentiometer Features

Adjustable potentiometer is just a kind of resistor. The resistance is changed by rotating the potentiometer, so is the voltage, speed, brightness and temperature. It is an analog electronic component, which has two states of 0 and 1(high level and low level). The analog quantity is different. Its data state presents a linear state such as 1 to 1000.

4.Circuit Connection

In this experiment, we will convert the resistance value of the potentiometer to analog ones and display it on the screen.

This is an application you need to master well for our future experiments.

Connection for V4.0

Connection for 2560

5.Sample Code

The program compiling is simple. An analogRead () Statement can read the value of the interface. The A/D acquisition of Arduino 328 is in 10 bits, so the value it reads is among 0 to 1023.

One difficulty in this project is to display the value on the screen, which is actually easy to learn.

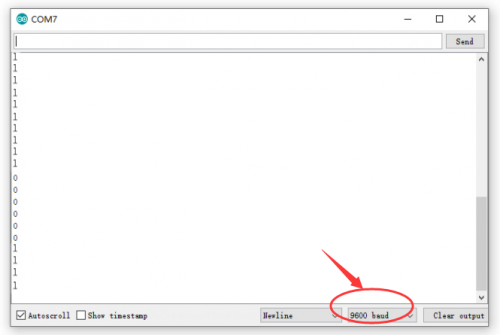

First, you need to set the baud rate in voidsetup (). Displaying the value is a communication between Arduino and PC, so the baud rate of the Arduino should match the one in the PC’s software set up. Otherwise, the display will be messy codes or no display at all.

In the lower right corner of the Arduino software monitor window, there is a button for baud rate set up. The set up here needs to match the one in the program. The statement in the program is Serial.begin(); enclosed is the baud rate value, followed by statement for displaying. You can either use Serial.print() or Serial.println() statement.

/*

keyestudio super learning kit

Project 15

Potentiometer

http//www.keyestudio.com

*/

int potpin=0;// initialize analog pin 0

int ledpin=13;// initialize digital pin 13

int val=0;// define val, assign initial value 0

void setup()

{

pinMode(ledpin,OUTPUT);// set digital pin as “output”

Serial.begin(9600);// set baud rate at 9600

}

void loop()

{

digitalWrite(ledpin,HIGH);// turn on the LED on pin 13

delay(50);// wait for 0.05 second

digitalWrite(ledpin,LOW);// turn off the LED on pin 13

delay(50);// wait for 0.05 second

val=analogRead(potpin);// read the analog value of analog pin 0, and assign it to val

Serial.println(val);// display val’s value

}

//////////////////////////////////////////////////////////////////

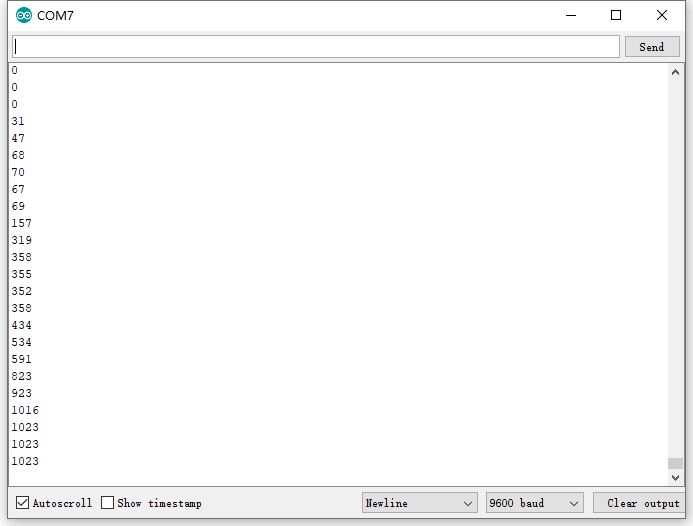

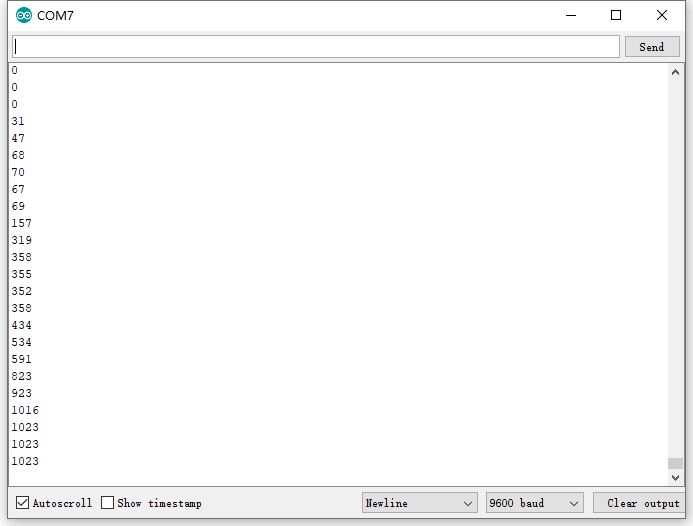

6.Test Result

The Sample Code uses the built-in LED connected to pin 13.

Each time the device reads a value, the LED blinks. When you rotate the potentiometer knob, you can see the displayed value change. The reading of analog value is a very common function since most sensors output analog value. After calculation, you can get the corresponding value you need.

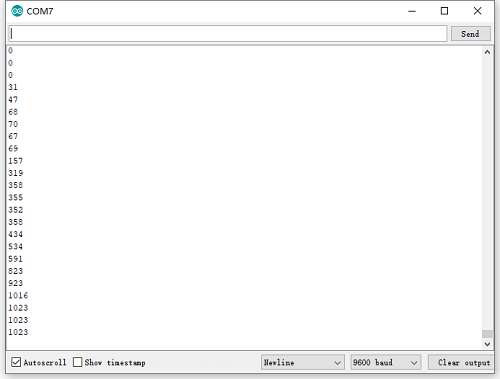

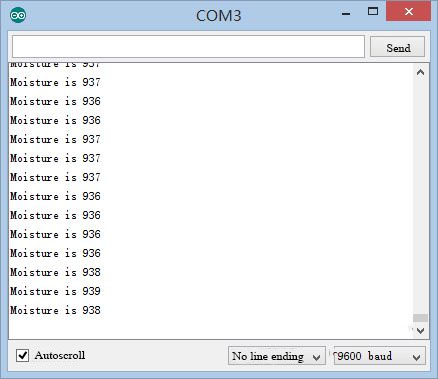

Below figure shows the analog value it reads.

The experiment is now completed. Thank you!

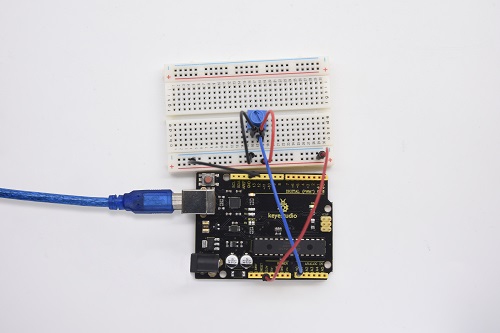

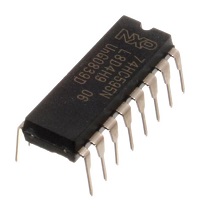

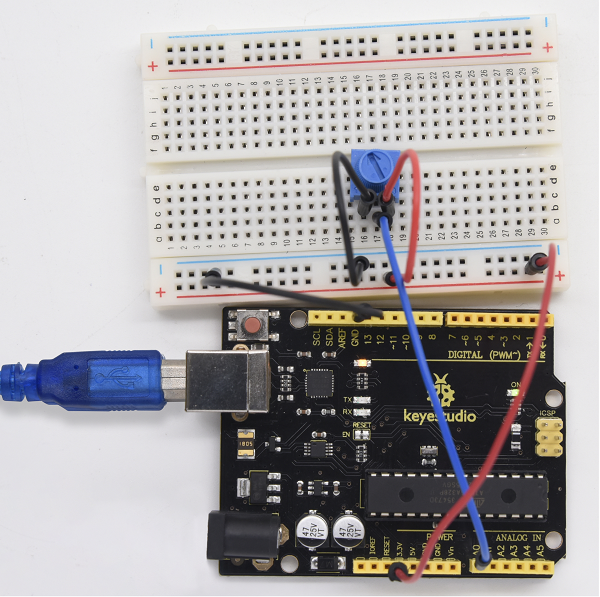

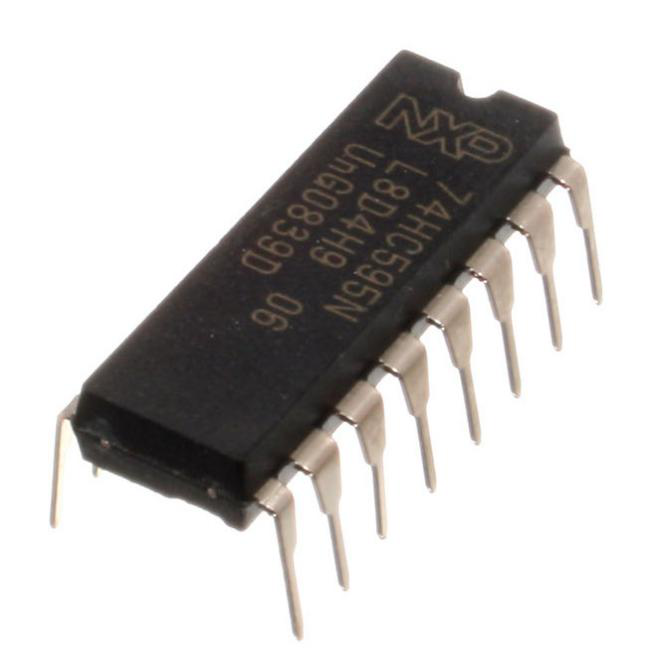

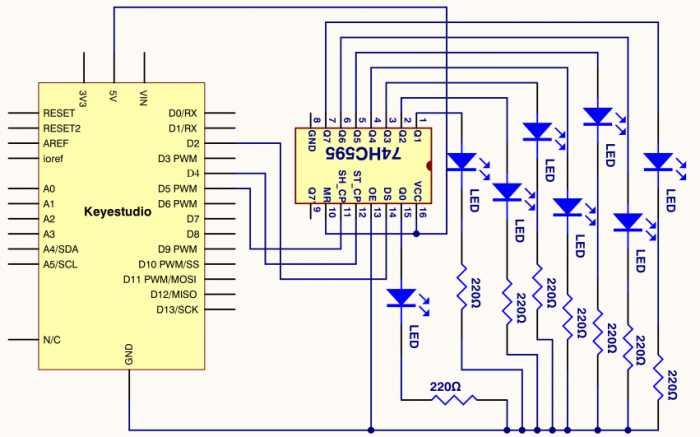

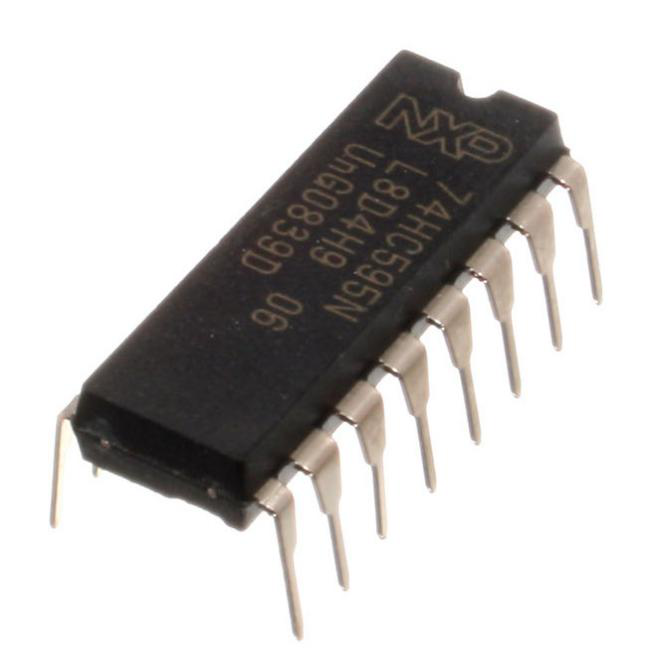

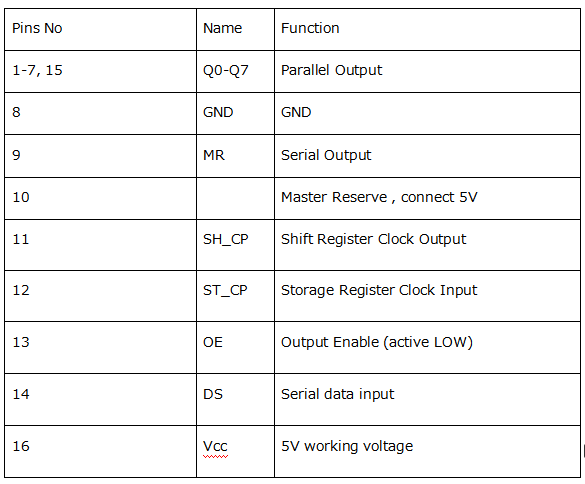

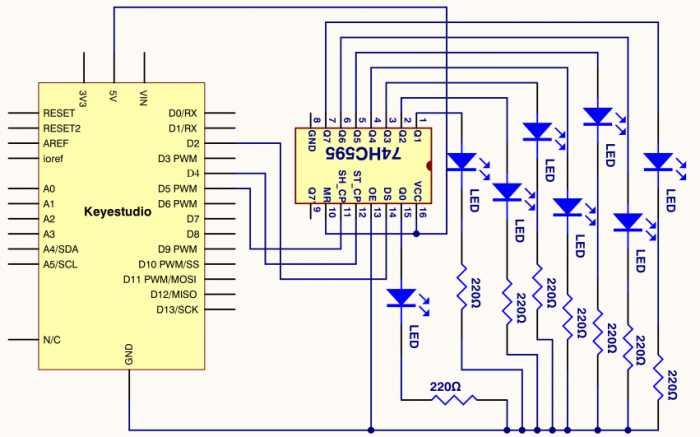

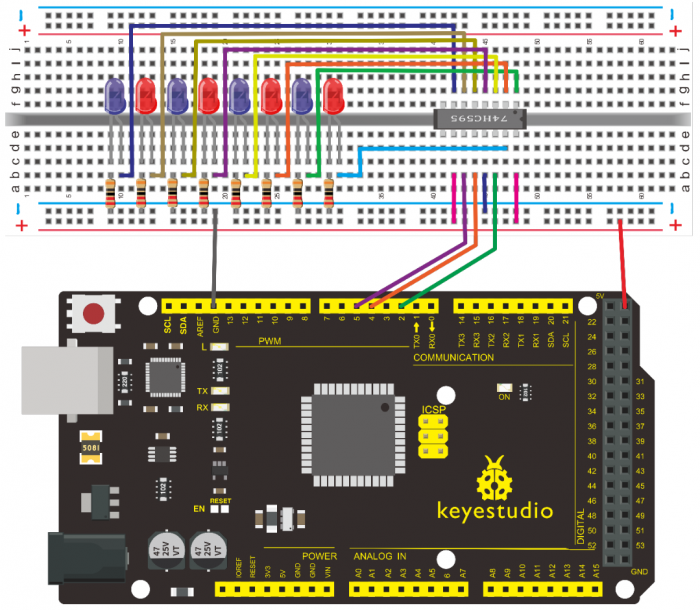

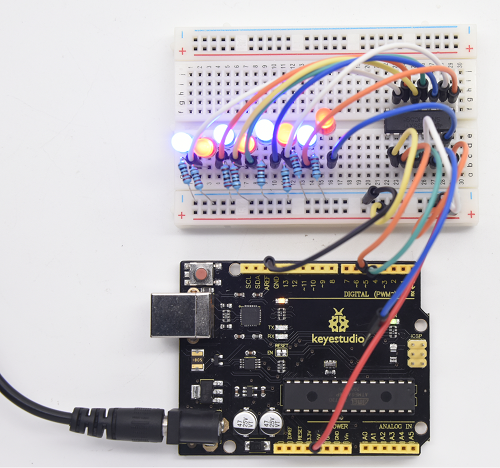

Project 16: 74HC595 chip

1.Introduction

74HC595 chip is a serial output and parallel output device. To put it simply, 74HC595 chip is a combination of 8-digit shifting register, memorizer and equipped with tri-state output.

Here, we use it to control 8 LEDs. You may wonder why use a 74HC595 to control LED? Well, think about how many I/O it takes for an Arduino to control 8 LEDs? Yes, 8.

For an Arduino 328, it has only 20 I/O including analog ports. To save port resources, using 74HC595 enables us to use 3 digital I/O ports to control 8 LEDs!

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- 74HC595 chip*1

- Red M5 LED*4

- Green M5 LED*4

- 220Ω Resistor*8

- Breadboard*1

- Breadboard Jumper Wires

- USB cable*1

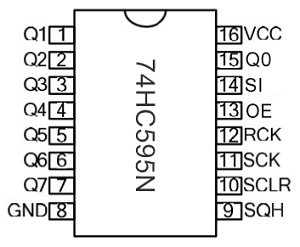

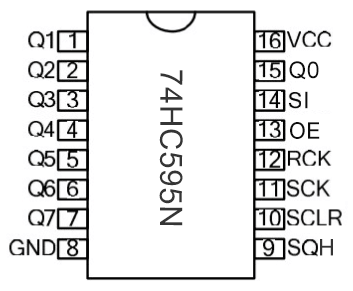

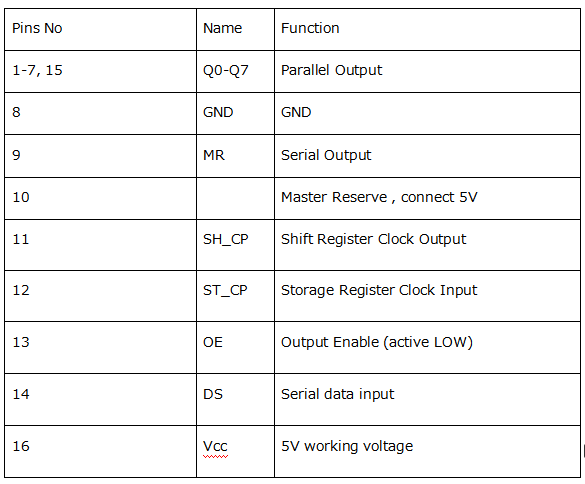

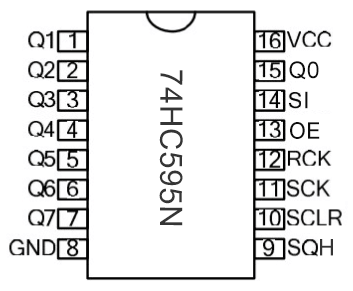

3.Pins Description:

- VCC and GND are used to supply power for chip, the working voltage is 5V.

- Q0~Q7:This eight pins are output pins.

- DS pin is serial input pin, we need to write data into this pin by bit.

- STCP is a latch pin. The data can be copied to latch and output in parallel after 8-digit data of latch is all transmitted.

- SHCP is a clock pin. The data can be written into storage register.

- OE is an output enable pin, which is used to make sure if the data of latch is input into Q0-Q7 pins. When in low level, high level is not output. In this experiment, we directly connect to GND to keep low level output data.

- MR is a pin to initialize the pin of storage register. Initialize the internal storage register when low level. In this experiment, we connect to VCC to keep high level.

- Q7S pin is a serial output pin, which is specially used for chip cascade.

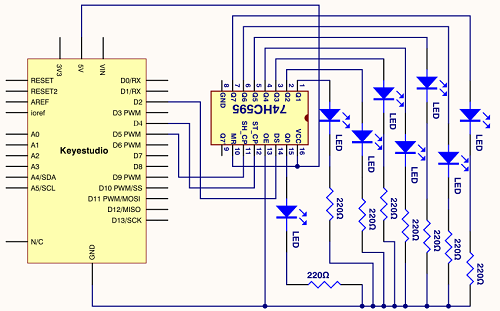

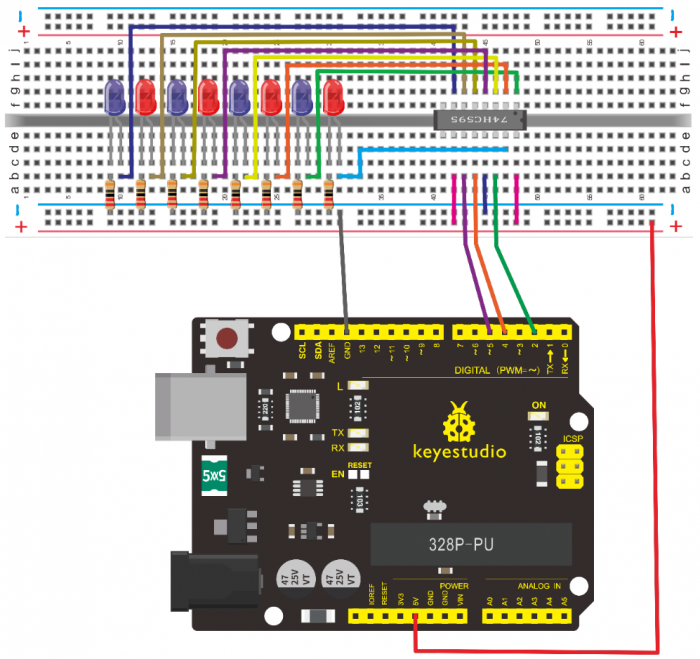

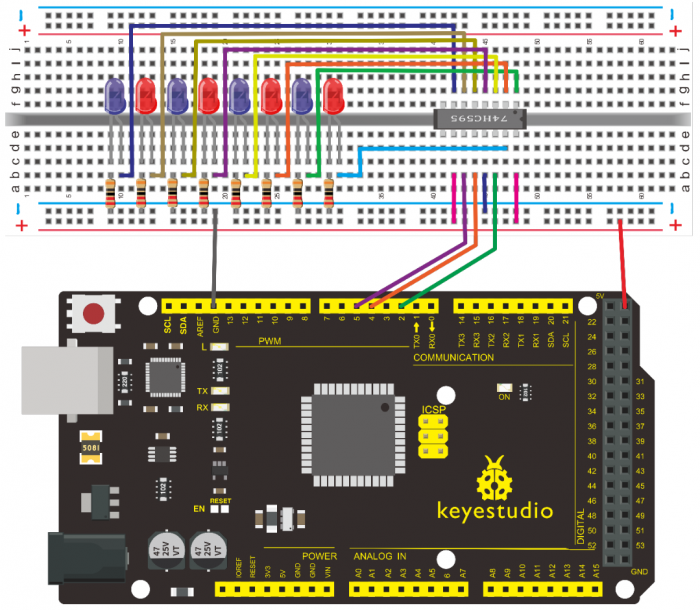

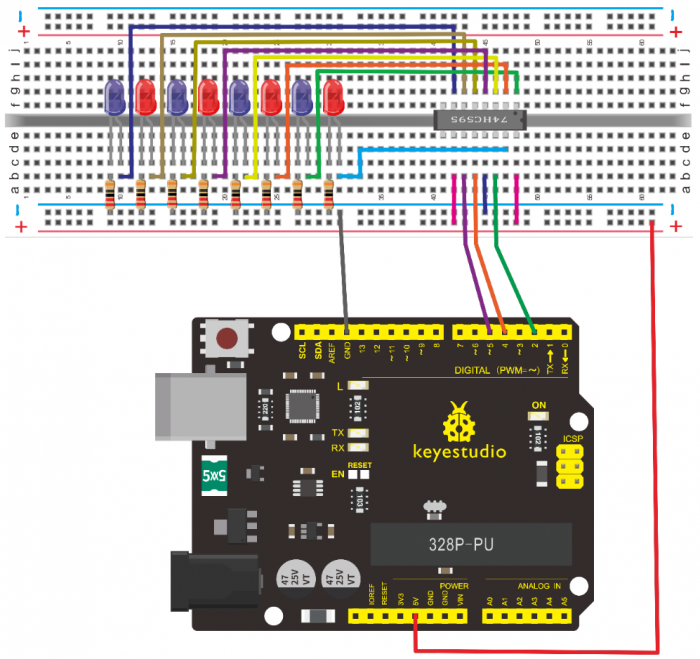

4.Circuit Connection

Connection for V4.0

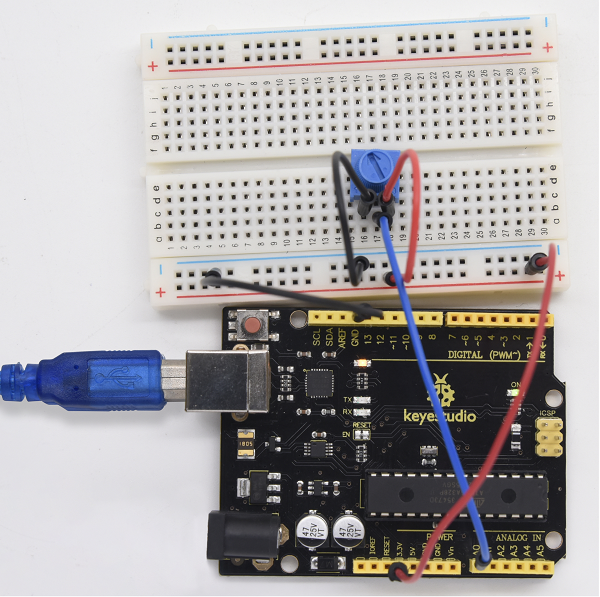

Connection for 2560 R3

The circuit may seem complicated, but once you wire it in order, you will find it more easier!

5.Sample Code

/*

keyestudio super learning kit

Project 16

74hc595

http//www.keyestudio.com

*/

int data = 2;// set pin 14 of 74HC595as data input pin SI

int clock = 5;// set pin 11 of 74hc595 as clock pin SCK

int latch = 4;// set pin 12 of 74hc595 as output latch RCK

int ledState = 0;

const int ON = HIGH;

const int OFF = LOW;

void setup()

{

pinMode(data, OUTPUT);

pinMode(clock, OUTPUT);

pinMode(latch, OUTPUT);

}

void loop()

{

for(int i = 0; i < 256; i++)

{

updateLEDs(i);

delay(500);

}

}

void updateLEDs(int value)

{

digitalWrite(latch, LOW);//

shiftOut(data, clock, MSBFIRST, ~value);// serial data “output”, high level first

digitalWrite(latch, HIGH);// latch

}

//////////////////////////////////////////////////////////////////

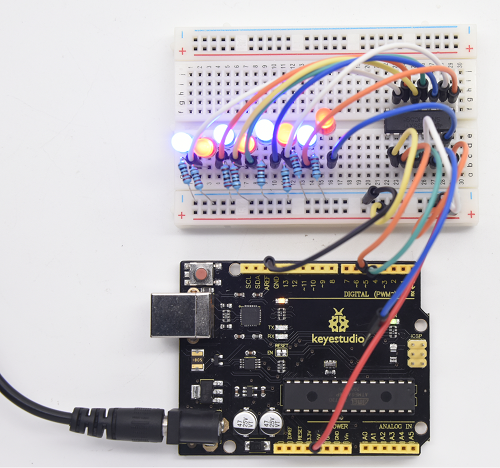

6.Test Result

After downloading the program, you can see 8 LEDs display 8-bit binary number.

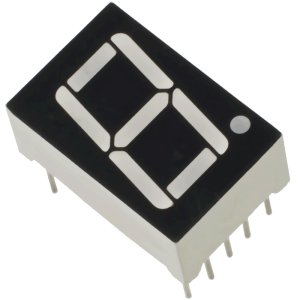

Project 17: 1-digit LED Segment Display

1.Introduction

LED segment displays are common for displaying numerical information. It’s widely applied on displays of electromagnetic oven, full automatic washing machine, water temperature display, electronic clock, etc. It is necessary for us to learn how it works.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- 1-digit LED Segment Display*1

- 220Ω Resistor*8

- Breadboard*1

- Breadboard Jumper Wires *several

- USB cable*1

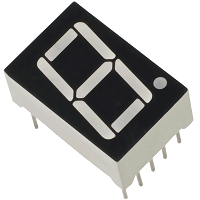

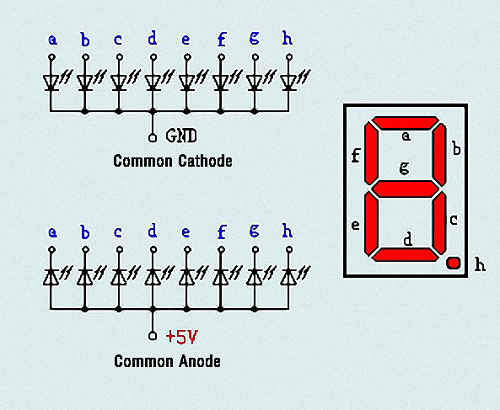

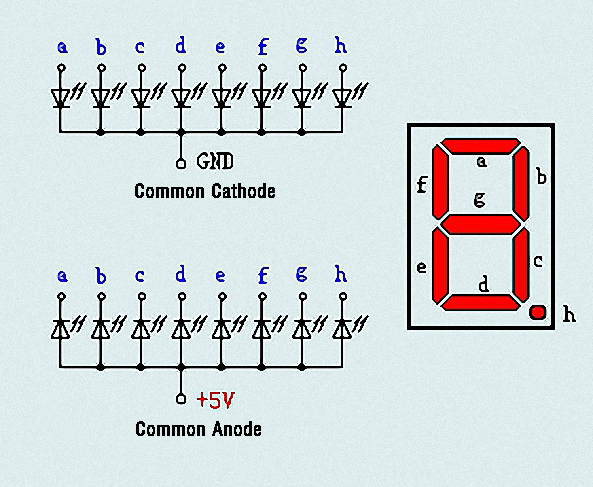

3.The display principle of the 1-digit LED Segment Display

LED segment display is a semiconductor light-emitting device. Its basic unit is a light-emitting diode (LED).

LED segment display can be divided into 7-segment display and 8-segment display according to the number of segments. 8-segment display has one more LED unit ( for decimal point display) than 7-segment one.

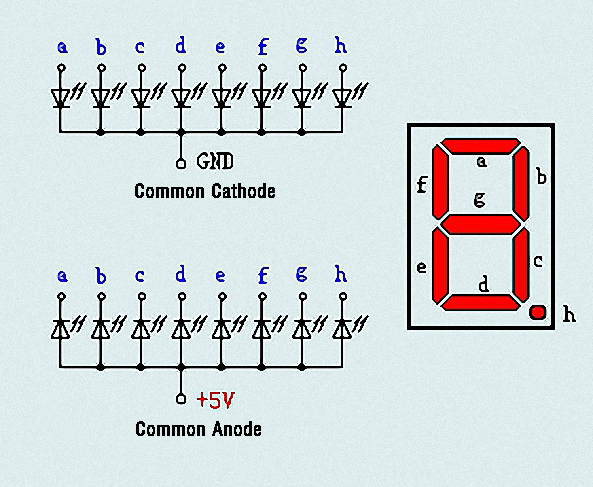

According to the wiring method of LED units, LED segment display can be divided into common anode display and common cathode display. Common anode display refers to the one that combine all the anodes of LED units into one common anode (COM).

For the common anode display, connect the common anode (COM) to +5V. When the cathode level of a certain segment is low, the segment is on; when the cathode level of a certain segment is high, the segment is off.

For the common cathode display, connect the common cathode (COM) to GND. When the anode level of a certain segment is high, the segment is on; when the anode level of a certain segment is low, the segment is off.

Each segment of the display consists of an LED. So when you use it, you also need to use a current-limiting resistor. Otherwise, LED will be burnt out.

In this experiment, we use a common cathode display. As we mentioned above, for common cathode display, connect the common cathode (COM) to GND. When the anode level of a certain segment is high, the segment is on; when the anode level of a certain segment is low, the segment is off.

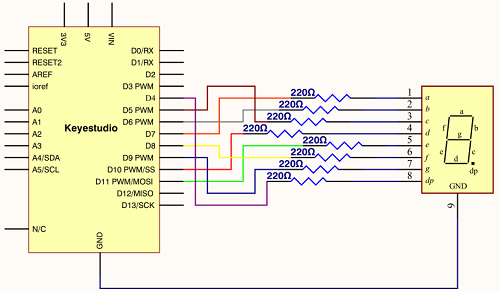

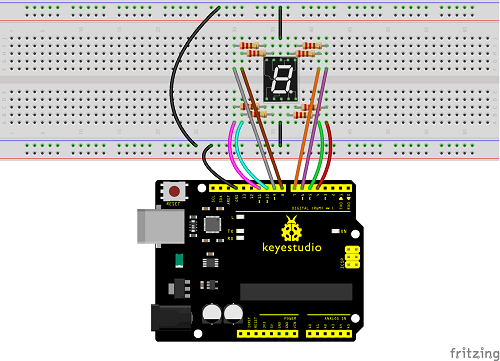

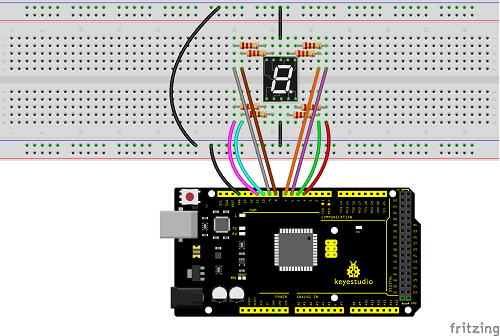

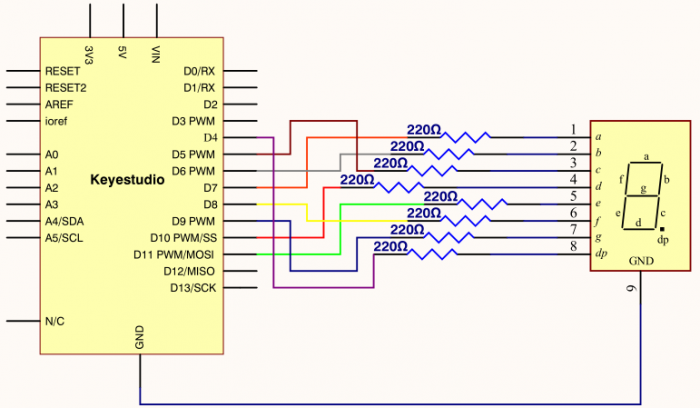

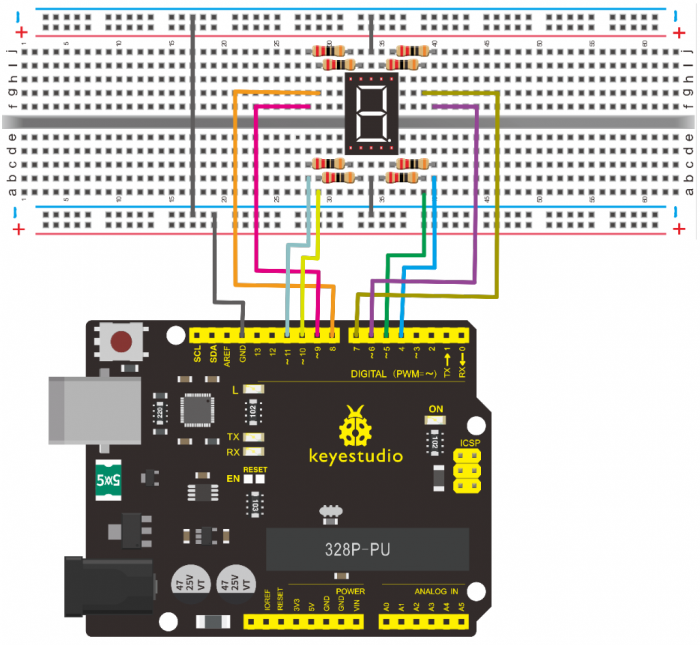

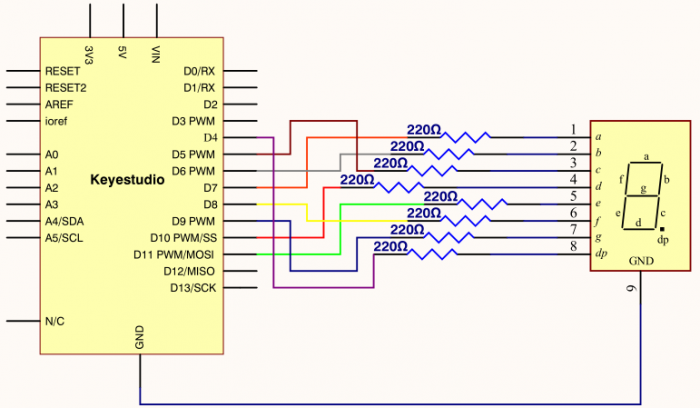

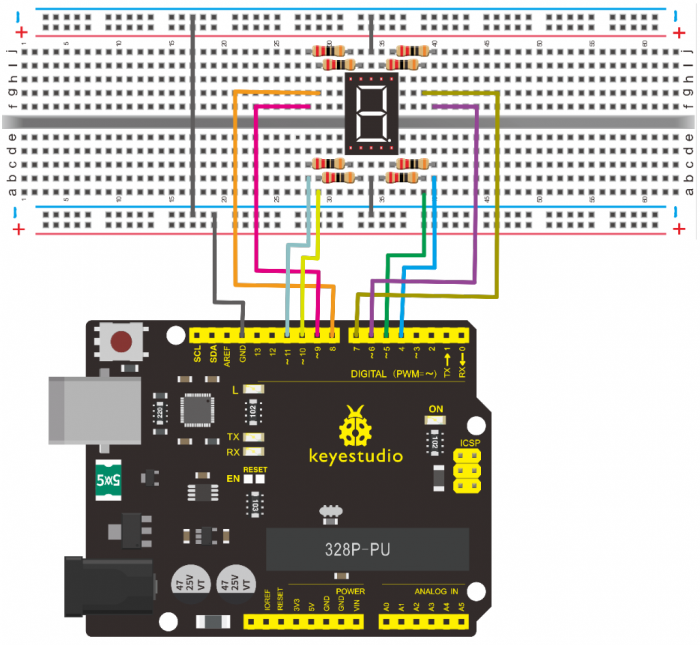

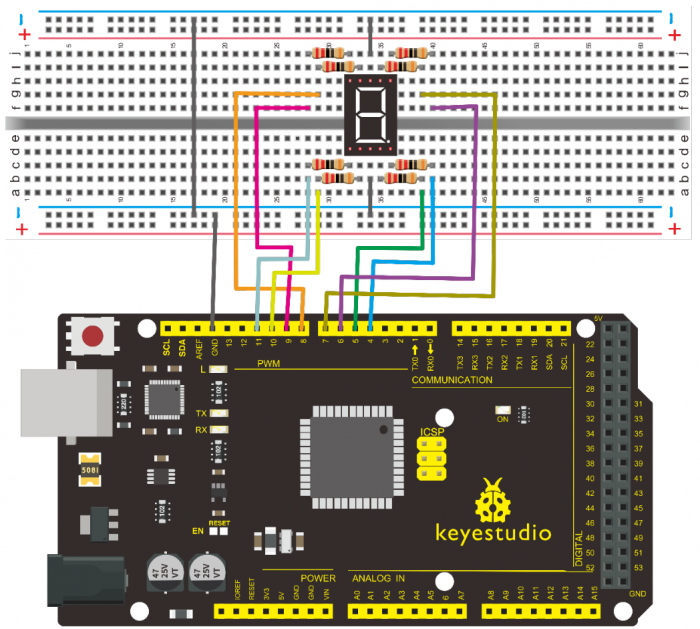

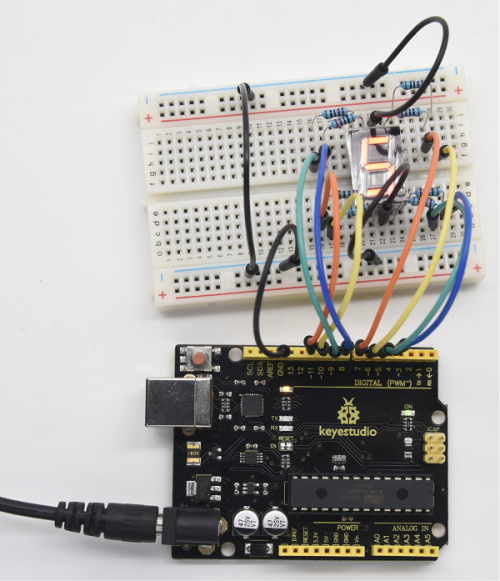

4.Circuit Connection

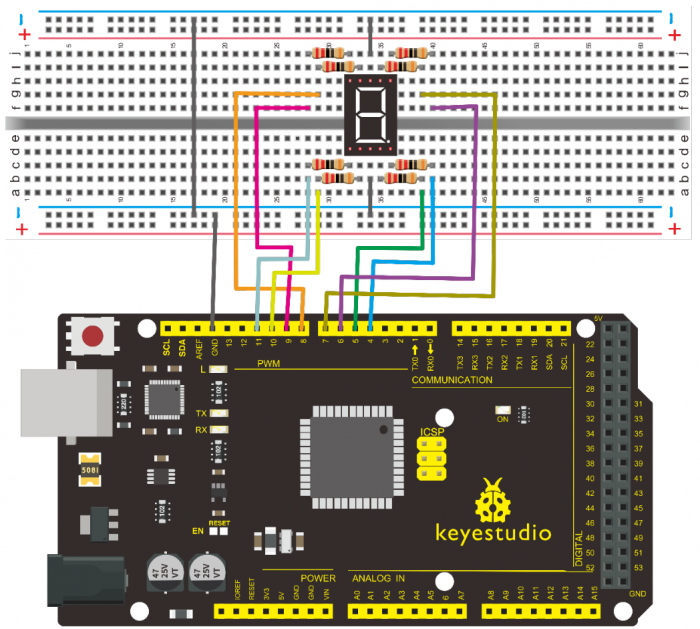

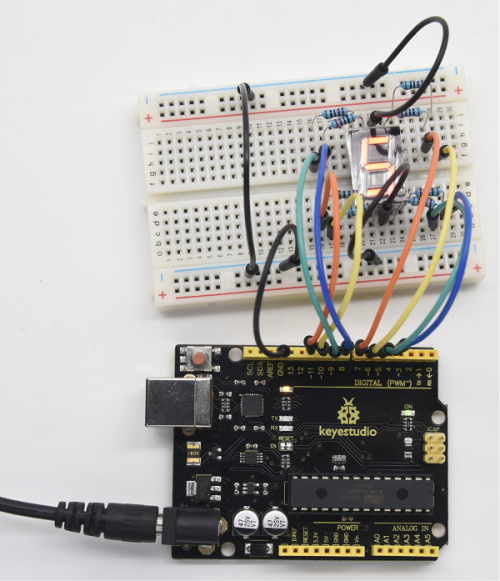

Connection for V4.0

Connection for 2560

5.Sample Code

There are seven segments for numerical display, one for decimal point display. Corresponding segments will be turned on when displaying certain numbers.

For example, when displaying number 1, b and c segments will be turned on. We compile a subprogram for each number, and compile the main program to display one number every 2 seconds, cycling display number 0 ~ 9.

The displaying time for each number is subject to the delay time, the longer the delay time, the longer the displaying time.

/*

keyestudio super learning kit

Project 17

1-digit LED Segment Display

http//www.keyestudio.com

*/

// set the IO pin for each segment

int a=7;// set digital pin 7 for segment a

int b=6;// set digital pin 6 for segment b

int c=5;// set digital pin 5 for segment c

int d=10;// set digital pin 10 for segment d

int e=11;// set digital pin 11 for segment e

int f=8;// set digital pin 8 for segment f

int g=9;// set digital pin 9 for segment g

int dp=4;// set digital pin 4 for segment dp

void digital_0(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,LOW);

digitalWrite(dp,LOW);

}

void digital_1(void) // display number 1

{

unsigned char j;

digitalWrite(c,HIGH);// set level as “high” for pin 5, turn on segment c

digitalWrite(b,HIGH);// turn on segment b

for(j=7;j<=11;j++)// turn off other segments

digitalWrite(j,LOW);

digitalWrite(dp,LOW);// turn off segment dp

}

void digital_2(void) // display number 2

{

unsigned char j;

digitalWrite(b,HIGH);

digitalWrite(a,HIGH);

for(j=9;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

digitalWrite(c,LOW);

digitalWrite(f,LOW);

}

void digital_3(void) // display number 3

{digitalWrite(g,HIGH);

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(dp,LOW);

digitalWrite(f,LOW);

digitalWrite(e,LOW);

}

void digital_4(void) // display number 4

{digitalWrite(c,HIGH);

digitalWrite(b,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

digitalWrite(a,LOW);

digitalWrite(e,LOW);

digitalWrite(d,LOW);

}

void digital_5(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b, LOW);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void digital_6(void) // display number 6

{

unsigned char j;

for(j=7;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(c,HIGH);

digitalWrite(dp,LOW);

digitalWrite(b,LOW);

}

void digital_7(void) // display number 7

{

unsigned char j;

for(j=5;j<=7;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

for(j=8;j<=11;j++)

digitalWrite(j,LOW);

}

void digital_8(void) // display number 8

{

unsigned char j;

for(j=5;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

}

void digital_9(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void setup()

{

int i;// set variable

for(i=4;i<=11;i++)

pinMode(i,OUTPUT);// set pin 4-11as “output”

}

void loop()

{

while(1)

{

digital_0();// display number 0

delay(1000);// wait for 1s

digital_1();// display number 1

delay(1000);// wait for 1s

digital_2();// display number 2

delay(1000); // wait for 1s

digital_3();// display number 3

delay(1000); // wait for 1s

digital_4();// display number 4

delay(1000); // wait for 1s

digital_5();// display number 5

delay(1000); // wait for 1s

digital_6();// display number 6

delay(1000); // wait for 1s

digital_7();// display number 7

delay(1000); // wait for 1s

digital_8();// display number 8

delay(1000); // wait for 1s

digital_9();// display number 9

delay(1000); // wait for 1s

}}

//////////////////////////////////////////////////////////////////

6.Test Result

LED segment display will show the number from 0 to 9.

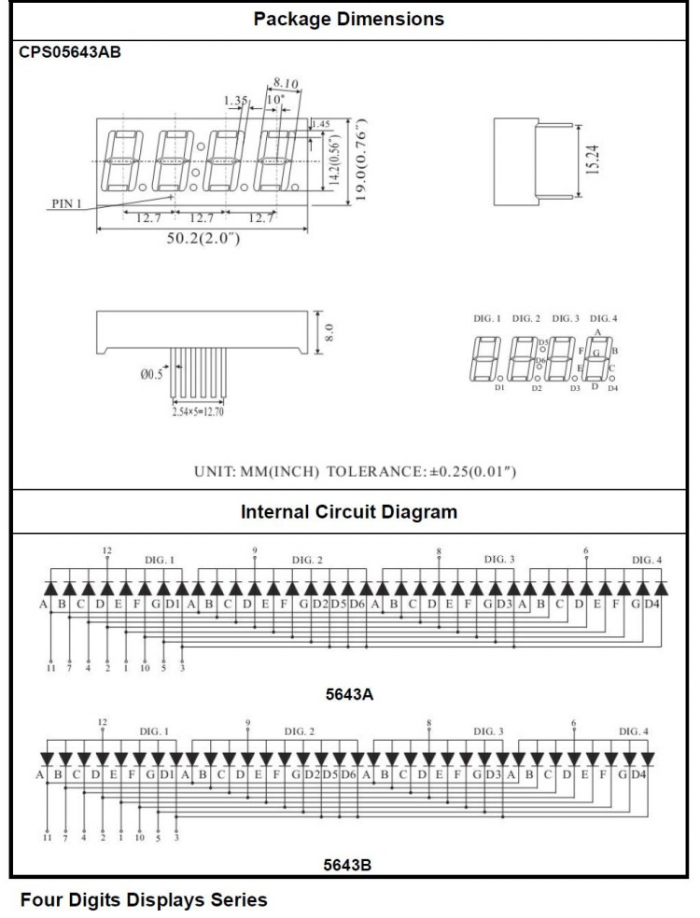

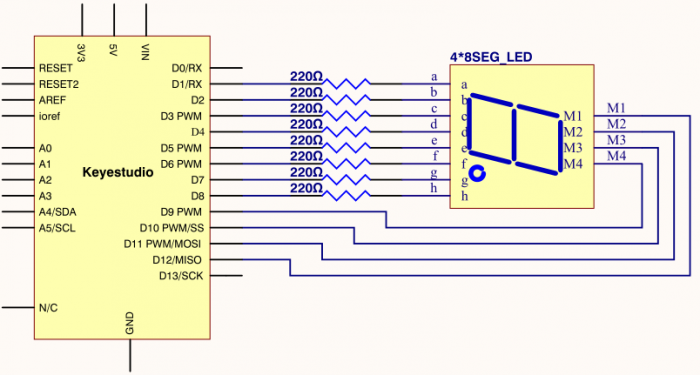

Project 18: 4-digit LED Segment Display

1.Introduction

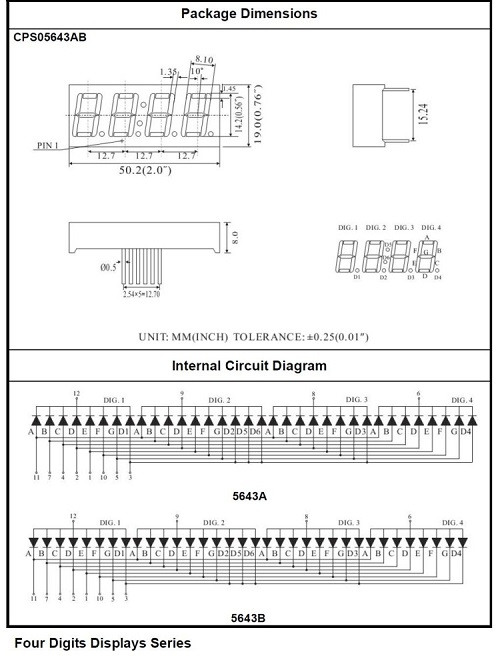

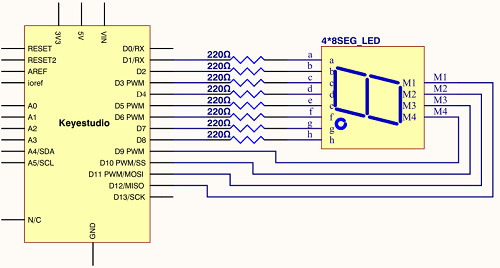

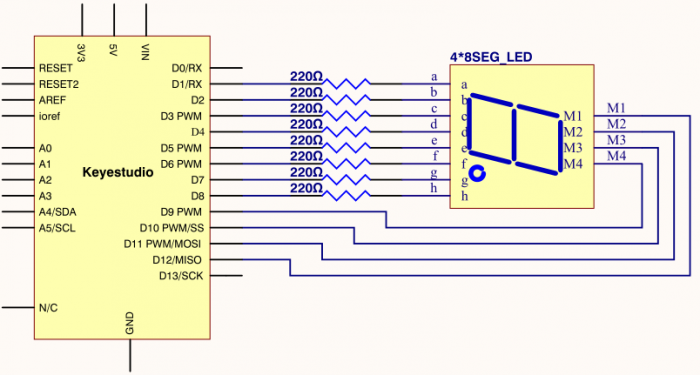

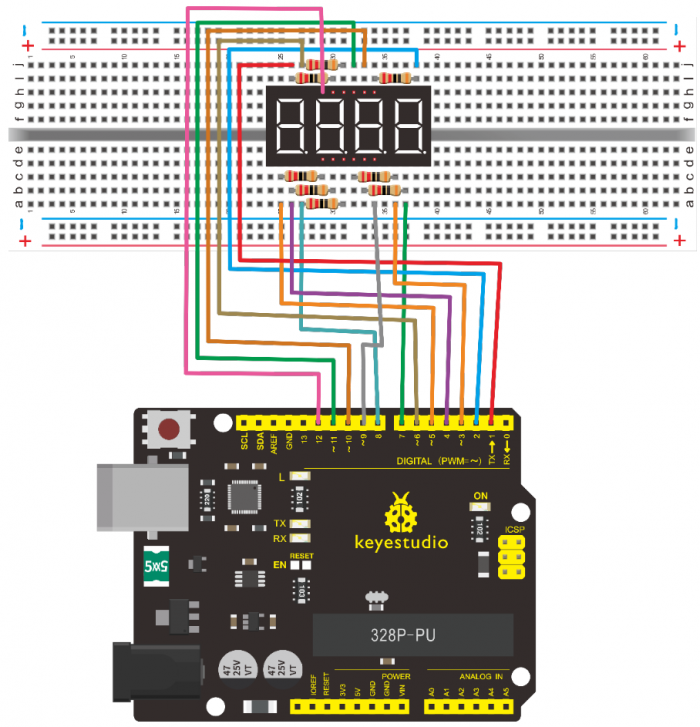

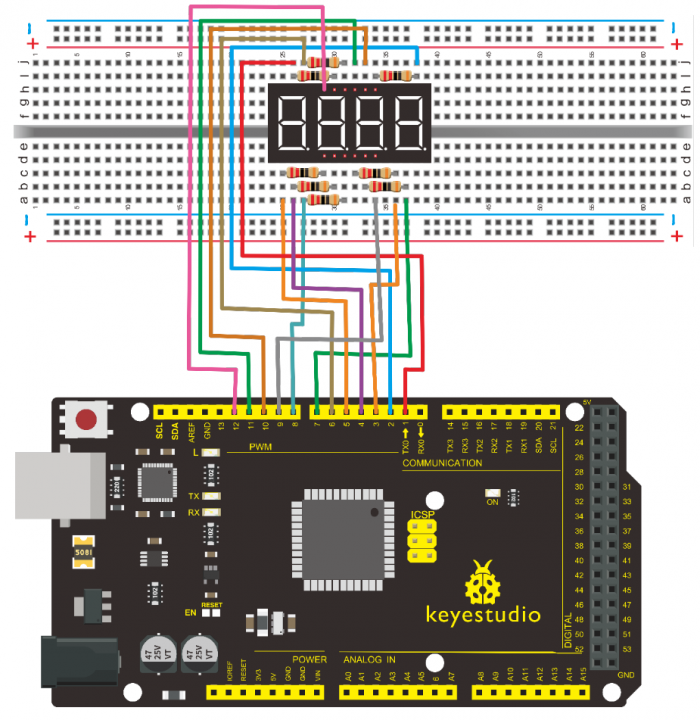

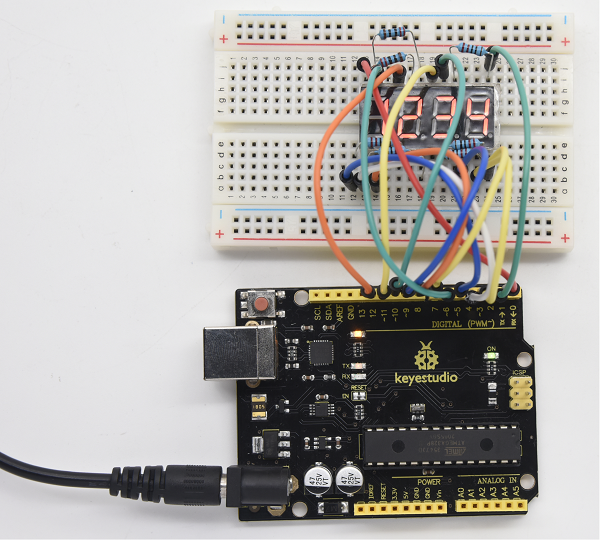

In this experiment, we use an Arduino to drive a common cathode, 4-digit, 7-segment LED display.

For LED display, current-limiting resistors are indispensable.

There are two wiring methods for Current-limiting resistor. One is to connect one resistor for each cathode end, 4 in total for d1-d4 cathode. An advantage for this method is that it requires fewer resistors, only 4. But it cannot maintain consistent brightness, 1, the brightest; 8, the least bright.

Another method is to connect one resistor to each pin. It guarantees consistent brightness, but requires more resistors.

In this experiment, we use 8 Resistors (220Ω). We use 220ΩResistors because of no 100Ω resistor available. If you use 100Ω, the displaying is more brighter.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- 4-digit LED Segment Display*1

- 220Ω Resistor*8

- Breadboard*1

- Breadboard Jumper Wires *several

- USB cable*1

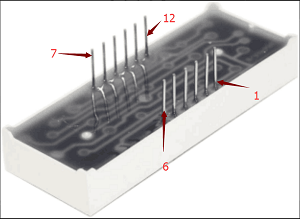

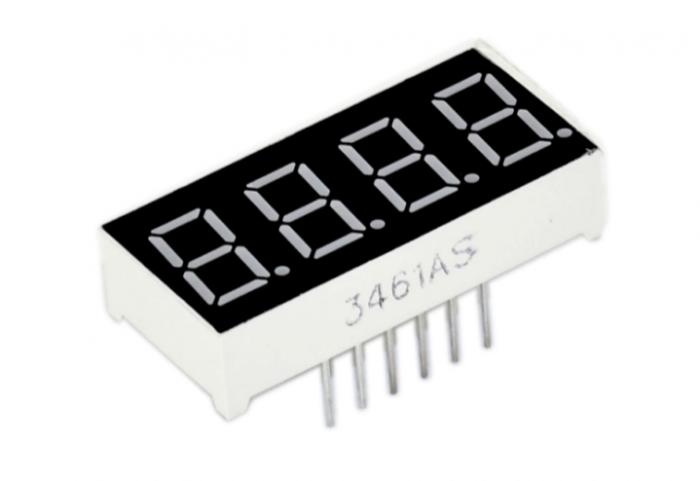

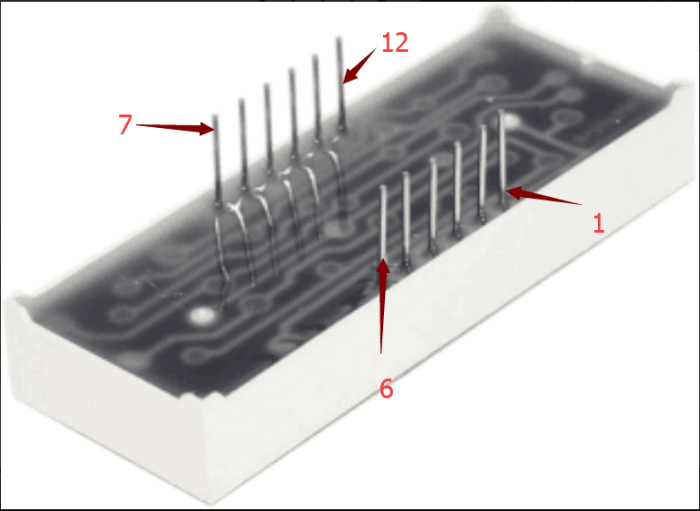

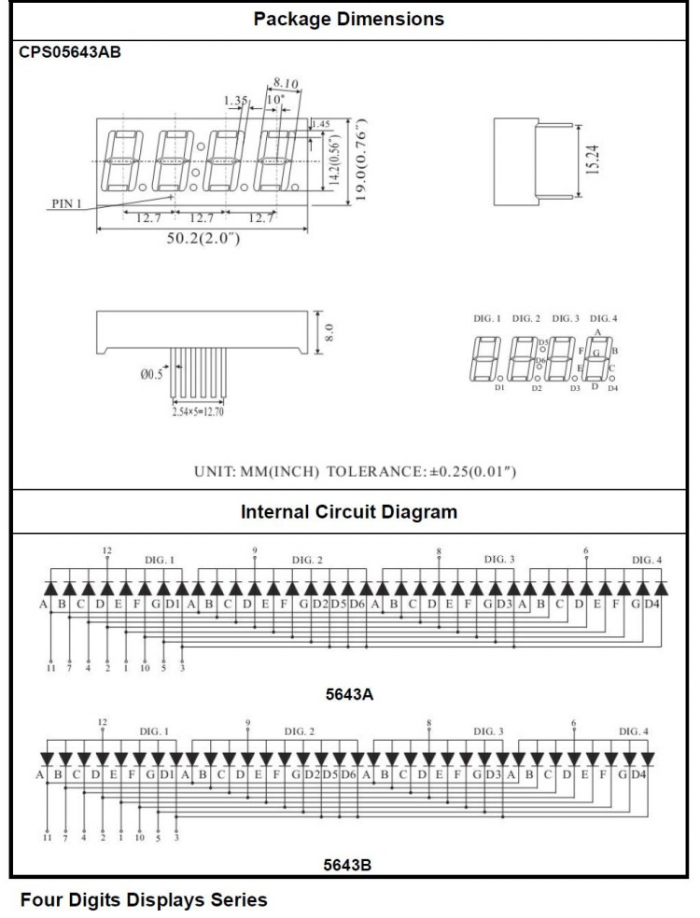

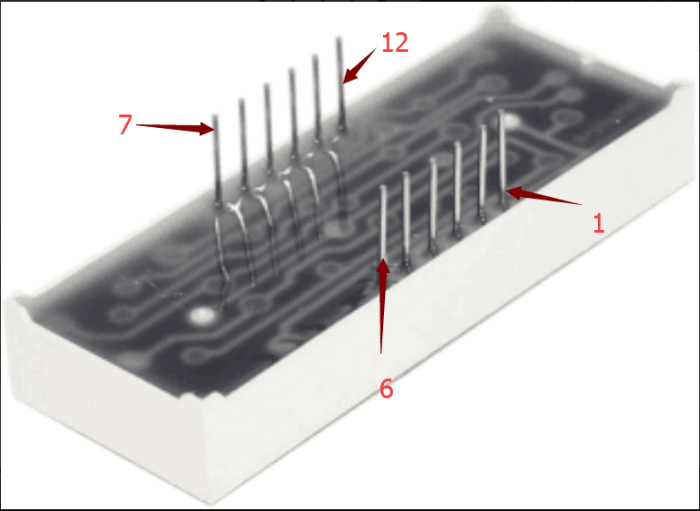

3.The display principle of the 4-digit display

For 4-digit display, there are 12 pins in total. When you place the decimal point downward, the pin on the lower left part is refer to as 1, the upper left part 12. Shown below.

4.Circuit Connection

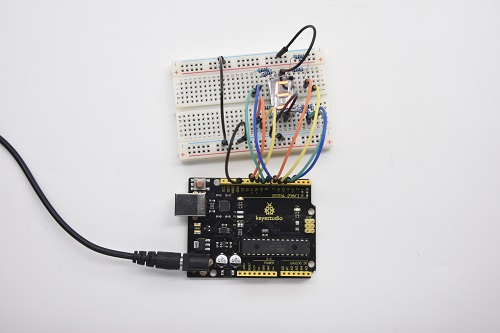

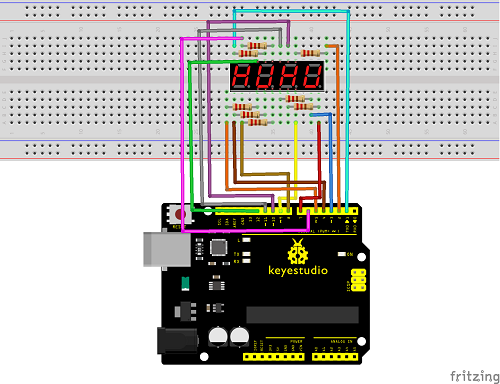

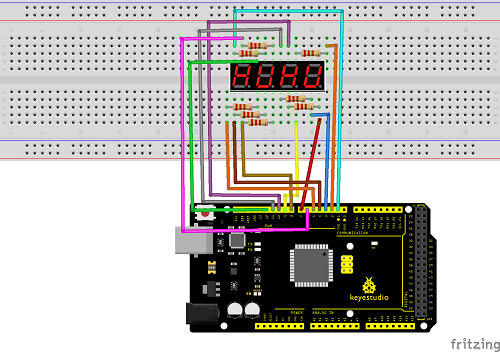

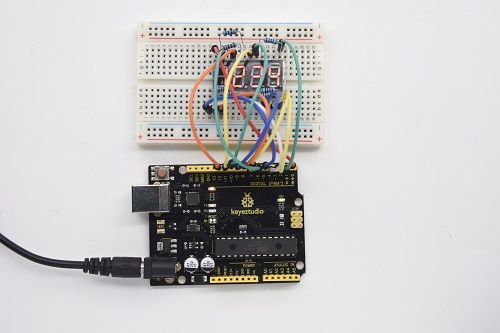

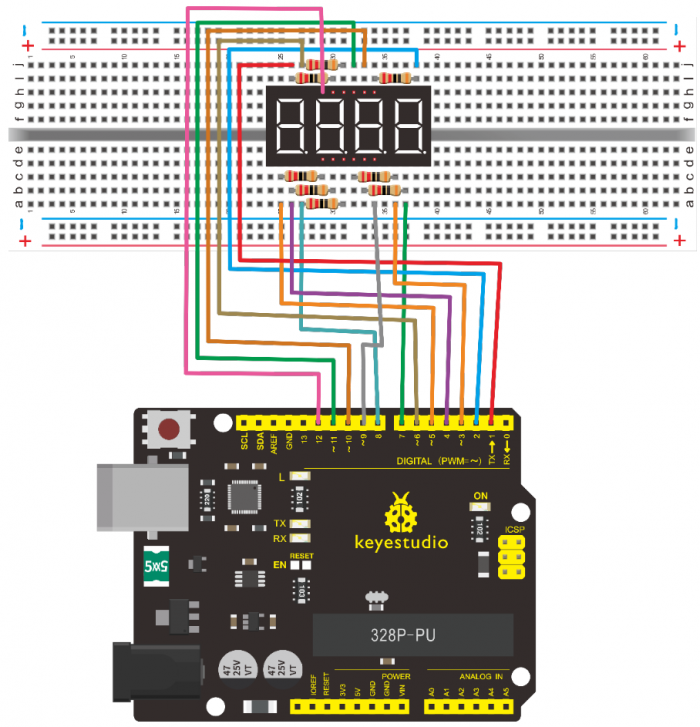

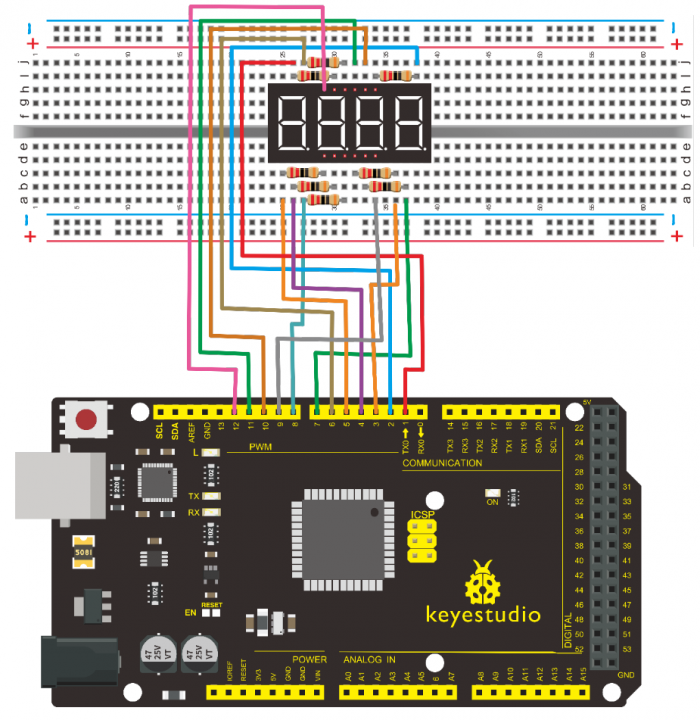

Connection for V4.0

Connection for 2560 R3

5.Sample Code

/*

keyestudio super learning kit

Project 18

4-digit LED Segment Display

http//www.keyestudio.com

*/

// display 1234

// select pin for cathode

int a = 1;

int b = 2;

int c = 3;

int d = 4;

int e = 5;

int f = 6;

int g = 7;

int dp = 8;

// select pin for anode

int d4 = 9;

int d3 = 10;

int d2 = 11;

int d1 = 12;

// set variable

long n = 1230;

int x = 100;

int del = 55; // fine adjustment for clock

void setup()

{

pinMode(d1, OUTPUT);

pinMode(d2, OUTPUT);

pinMode(d3, OUTPUT);

pinMode(d4, OUTPUT);

pinMode(a, OUTPUT);

pinMode(b, OUTPUT);

pinMode(c, OUTPUT);

pinMode(d, OUTPUT);

pinMode(e, OUTPUT);

pinMode(f, OUTPUT);

pinMode(g, OUTPUT);

pinMode(dp, OUTPUT);

}

/////////////////////////////////////////////////////////////

void loop()

{

Display(1, 1);

Display(2, 2);

Display(3, 3);

Display(4, 4);

}

///////////////////////////////////////////////////////////////

void WeiXuan(unsigned char n)//

{

switch(n)

{

case 1:

digitalWrite(d1,LOW);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

case 2:

digitalWrite(d1, HIGH);

digitalWrite(d2, LOW);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

case 3:

digitalWrite(d1,HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, LOW);

digitalWrite(d4, HIGH);

break;

case 4:

digitalWrite(d1, HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, LOW);

break;

default :

digitalWrite(d1, HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

}

}

void Num_0()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, LOW);

digitalWrite(dp,LOW);

}

void Num_1()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp,LOW);

}

void Num_2()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, LOW);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_3()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_4()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_5()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_6()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_7()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp,LOW);

}

void Num_8()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Num_9()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp,LOW);

}

void Clear() // clear the screen

{

digitalWrite(a, LOW);

digitalWrite(b, LOW);

digitalWrite(c, LOW);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp,LOW);

}

void pickNumber(unsigned char n)// select number

{

switch(n)

{

case 0:Num_0();

break;

case 1:Num_1();

break;

case 2:Num_2();

break;

case 3:Num_3();

break;

case 4:Num_4();

break;

case 5:Num_5();

break;

case 6:Num_6();

break;

case 7:Num_7();

break;

case 8:Num_8();

break;

case 9:Num_9();

break;

default:Clear();

break;

}

}

void Display(unsigned char x, unsigned char Number)// take x as coordinate and display number

{

WeiXuan(x);

pickNumber(Number);

delay(1);

Clear() ; // clear the screen

}

//////////////////////////////////////////////////////////

6.Test Result

Download the above code to the controller board, you can see the LED display shows the number 1234.

Note if it’s not displaying correctly, check the wiring.

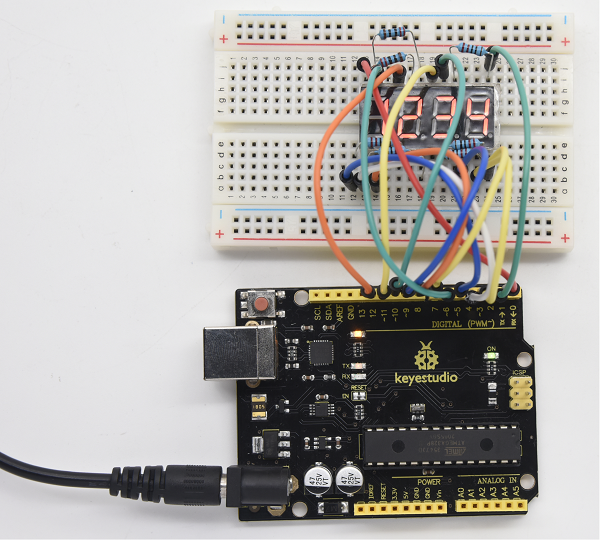

Project 19: 8*8 LED Matrix

1.Introduction

LED dot-matrix display can meet the needs of different applications, thus has a broad development prospect. With low-voltage scanning, LED dot-matrix has some advantages such as power saving, long service life, low cost, high brightness, wide angle of view, long visual range, waterproof, and numerous specifications.

This project, we will conduct an LED dot-matrix experiment to experience its charm firsthand.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- 1 * 8*8 Dot Matrix

- 8 * Resistor (220Ω)

- 1 * Breadboard

- 1 * USB Cable

- Several* Jumper Wires

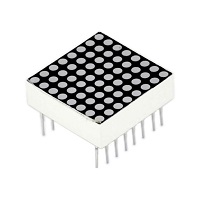

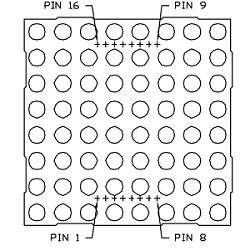

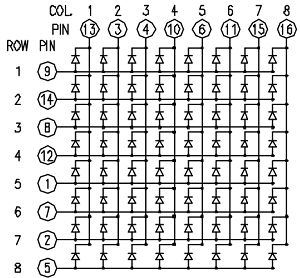

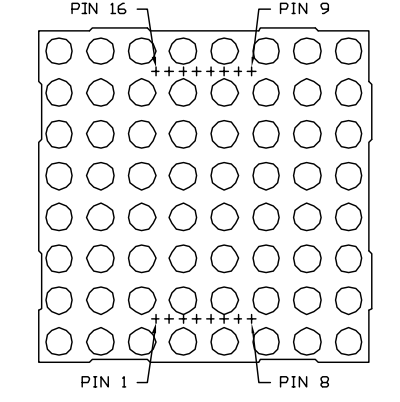

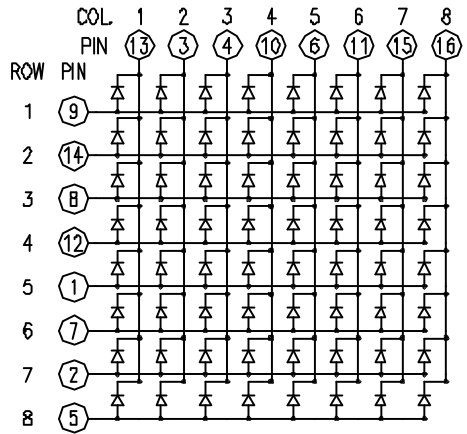

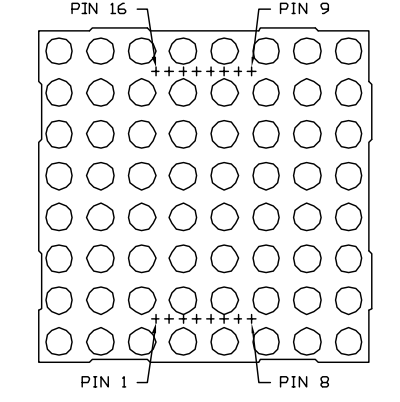

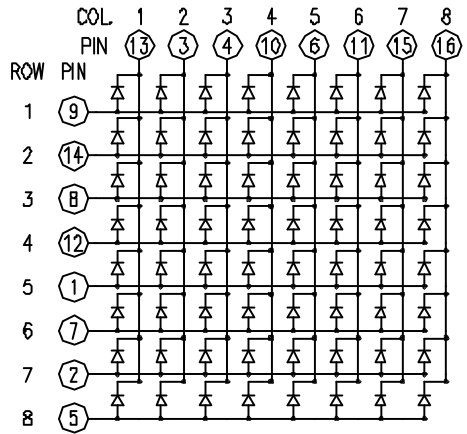

3.The display principle of the 8*8 dot-matrix

The external view of a dot-matrix is shown as follows

The 8*8 dot-matrix is made up of sixty-four LEDs, and each LED is placed at the cross point of a row and a column.

When the electrical level of a certain row is 1 and the electrical level of a certain column is 0, the corresponding LED will lighten. If you want to light the LED on the first dot, you should set pin 9 to high level and pin 13 to low level.

If you want to light LEDs on the first row, you should set pin 9 to high level and pins 13, 3, 4, 10, 6, 11, 15 and 16 to low level.

If you want to light the LEDs on the first column, set pin 13 to low level and pins 9, 14, 8, 12, 1, 7, 2 and 5 to high level.

The internal view of a dot-matrix is shown as follows

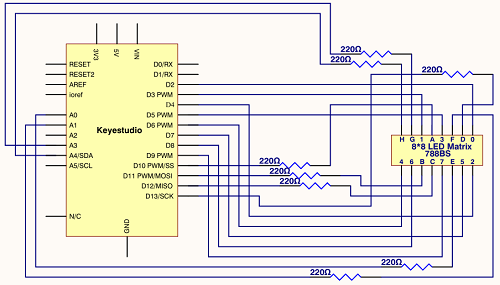

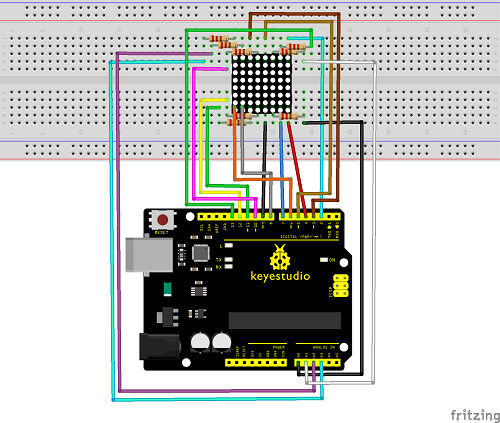

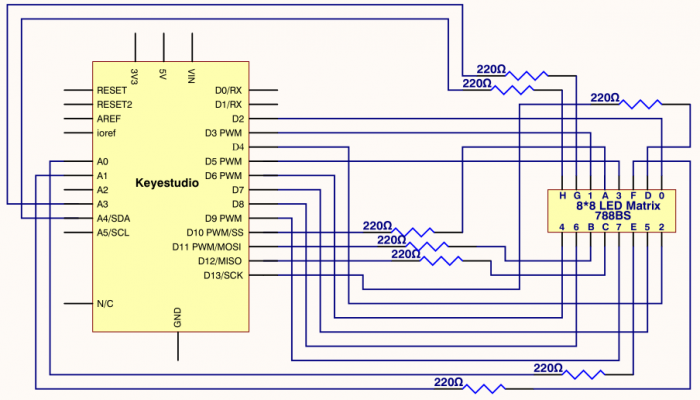

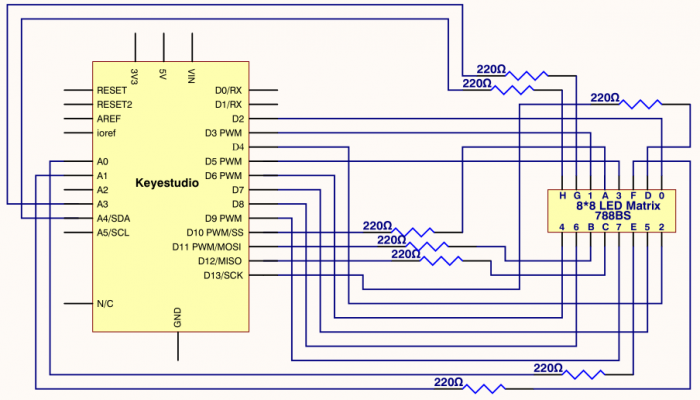

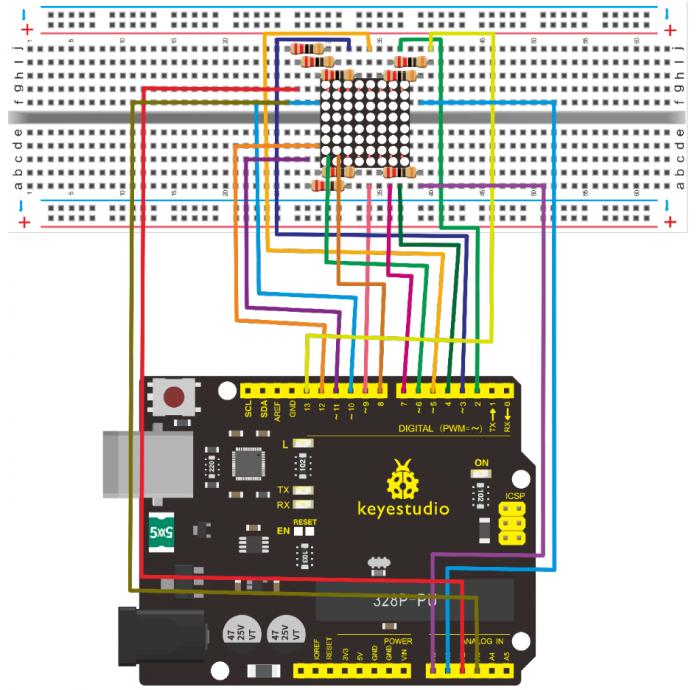

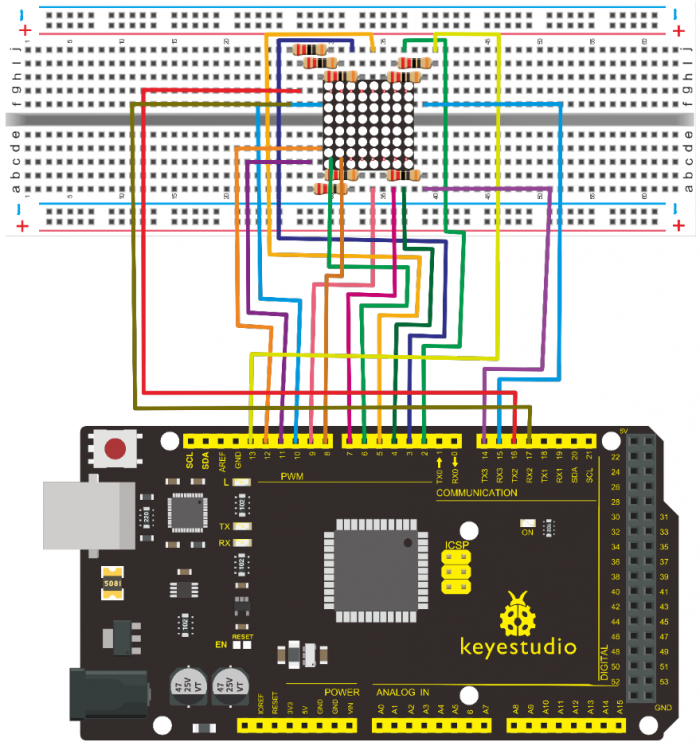

4.Circuit Connection

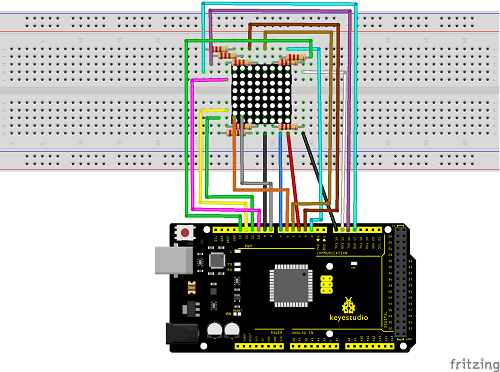

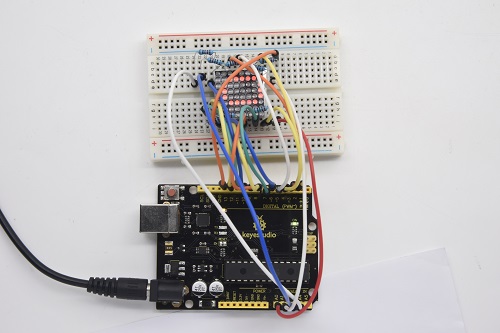

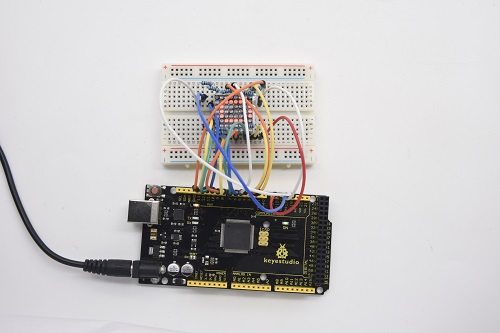

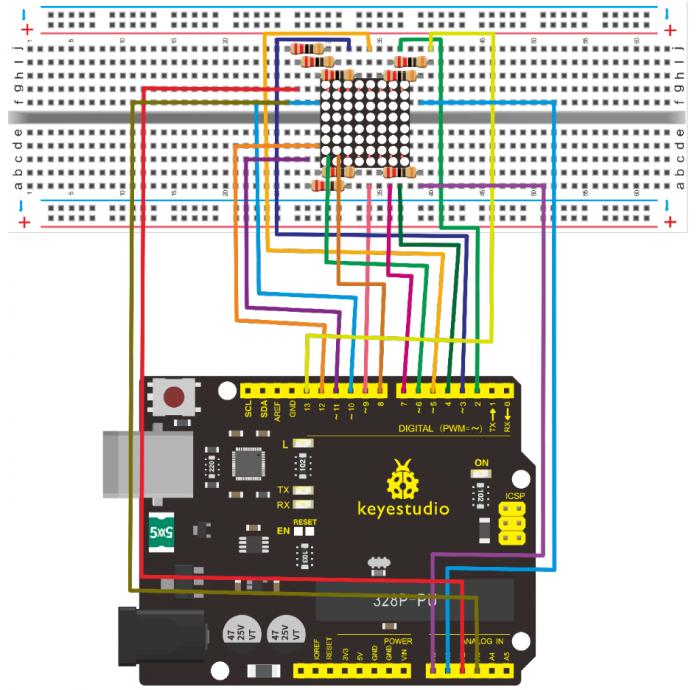

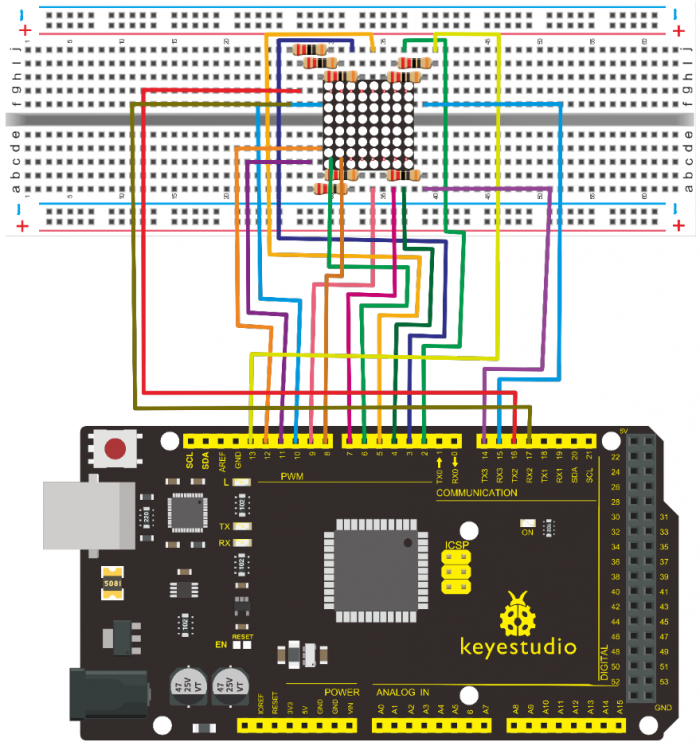

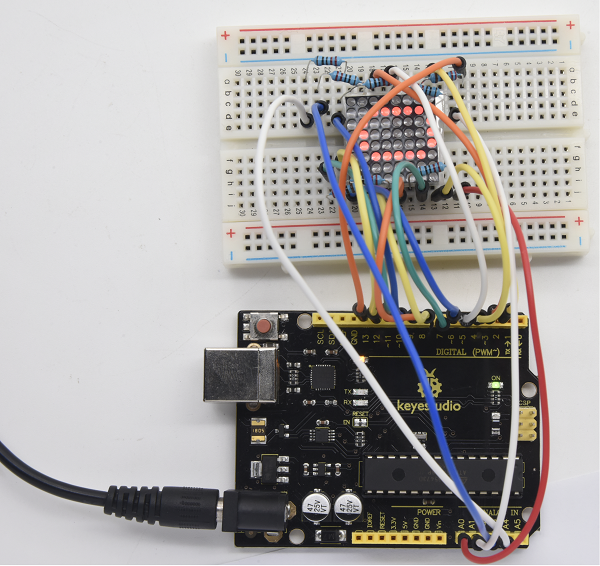

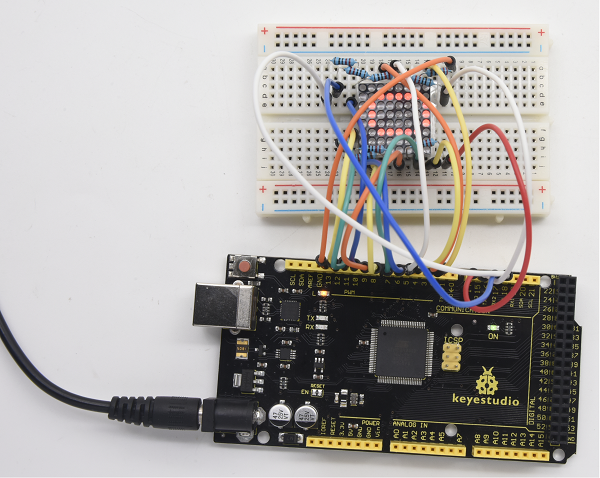

Connection for V4.0

Connection for 2560 R3

5.Sample Code for displaying “0”

/*

keyestudio super learning kit

Project 19

8*8 dot-matrix

http//www.keyestudio.com

*/

// set an array to store character of “0”

unsigned char Text[]={0x00,0x1c,0x22,0x22,0x22,0x22,0x22,0x1c};

void Draw_point(unsigned char x,unsigned char y)// point drawing function

{ clear_();

digitalWrite(x+2, HIGH);

digitalWrite(y+10, LOW);

delay(1);

}

void show_num(void)// display function, call point drawing function

{

unsigned char i,j,data;

for(i=0;i<8;i++)

{

data=Text[i];

for(j=0;j<8;j++)

{

if(data & 0x01)Draw_point(j,i);

data>>=1;

}

}

}

void setup(){

int i = 0 ;

for(i=2;i<18;i++)

{

pinMode(i, OUTPUT);

}

clear_();

}

void loop()

{ show_num();

}

void clear_(void)// clear screen

{for(int i=2;i<10;i++)

digitalWrite(i, LOW);

for(int i=0;i<8;i++)

digitalWrite(i+10, HIGH);

}

//////////////////////////////////////////////////////////

6.Test Result

Burn the program into V4.0 board, the dot-matrix will display 0.

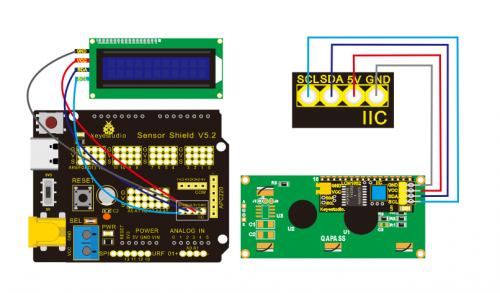

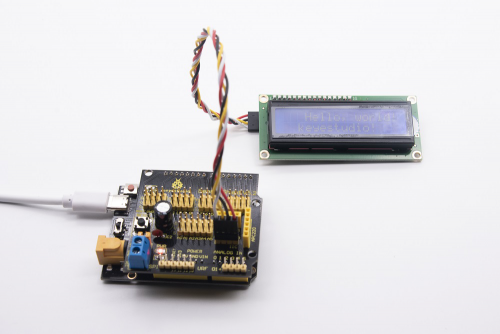

Project 20: 1602 LCD

1.Introduction

In this experiment, we use an Arduino to drive the 1602 LCD.

1602 LCD has wide applications. In the beginning, 1602 LCD uses a HD44780 controller.

Now, almost all 1602 LCD module uses a compatible IC, so their features are basically the same.

2.1602LCD Main Parameters

- V4.0 Board or MEGA 2650 Board*1

- Display capacity 16 * 2 characters

- Chip operating voltage 4.5 ~ 5.5V

- Working current 2.0mA (5.0V)

- Optimum working voltage of the module is 5.0V

- Character size 2.95 * 4.35 (W * H) mm

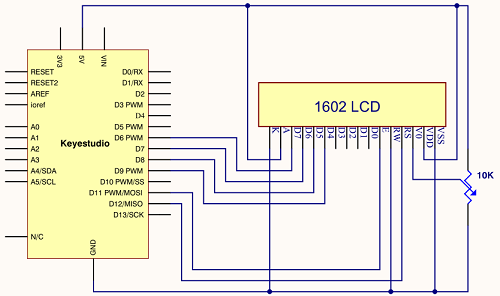

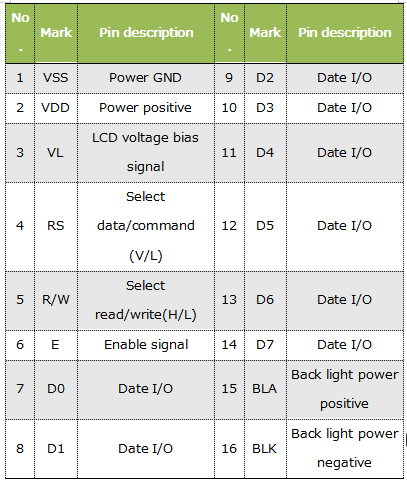

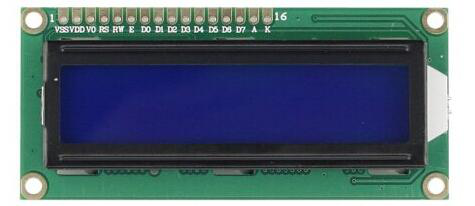

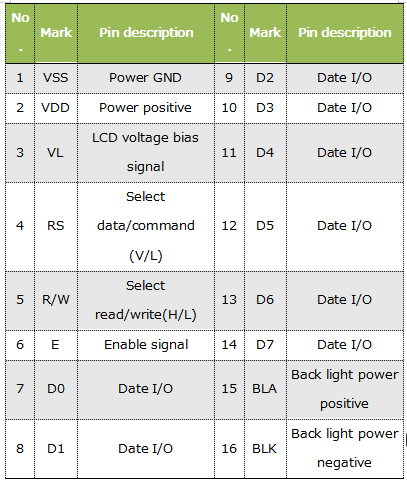

3.Pin description of 1602 LCD

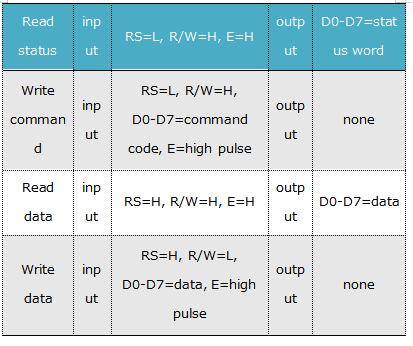

4.Interface Description

- 1.Two power pins, one for module power, another one for back light, generally use 5V. In this project, we use 3.3V for backlight.

- 2.VL is the pin for adjusting contrast ratio. It usually connects a potentiometer(no more than 5KΩ) in series for its adjustment.

- In this experiment, we use a 1KΩ resistor. For its connection, it has two methods, namely high potential and low potential. Here, we use low potential method; connect the resistor and then the GND.

- 3.RS is a very common pin in LCD. It’s a selecting pin for command/data. When the pin is in high level, it’s in data mode; when it’s in low level, it’s in command mode.

- 4.RW pin is also very common in LCD. It’s a selecting pin for read/write. When the pin is in high level, it’s in read operation; if in low level, it’s in write operation.

- 5.E pin is also very common in LCD. Usually, when the signal in the bus is stabilized, it sends out a positive pulse requiring read operation. When this pin is in high level, the bus is not allowed to have any change.

- 6.D0-D7 is 8-bit bidirectional parallel bus, used for command and data transmission.

- 7.BLA is anode for back light; BLK, cathode for back light.

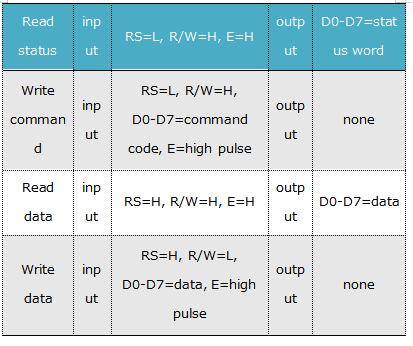

5.Four Basic Operations for 1602LCD

6.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- 1 * 1602 LCD

- 1 * Potentiometer

- 1 * Breadboard

- 1 * USB Cable

- Several* Jumper Wires

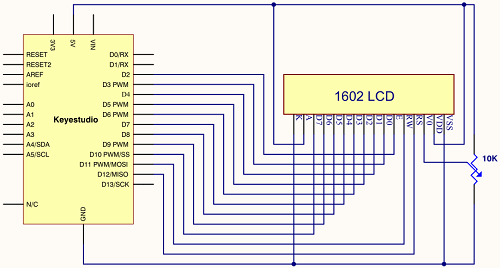

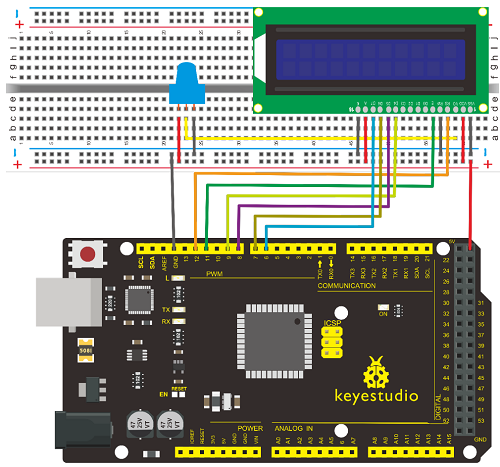

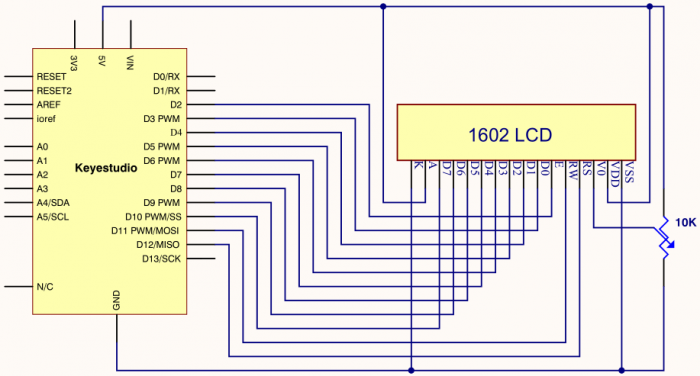

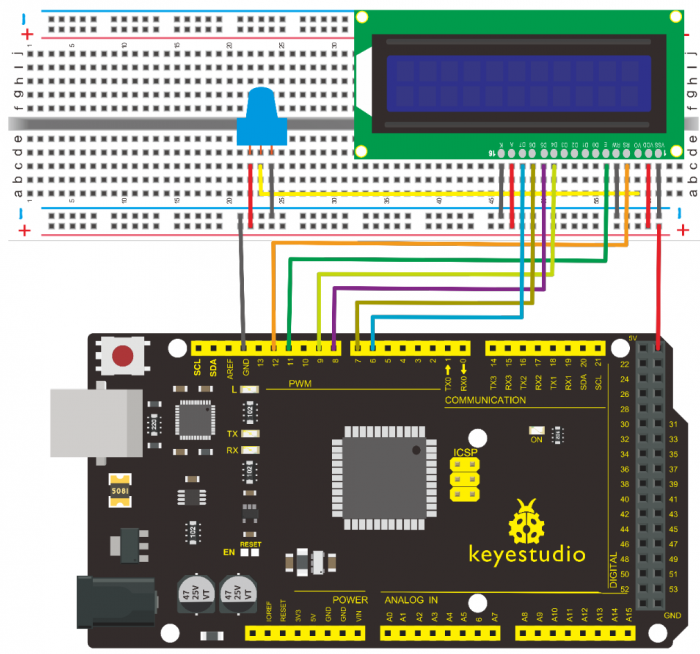

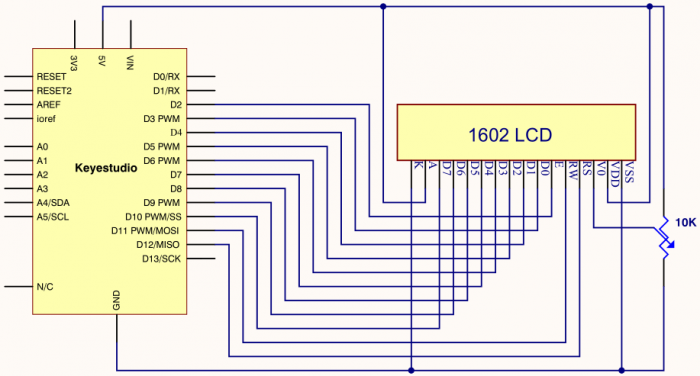

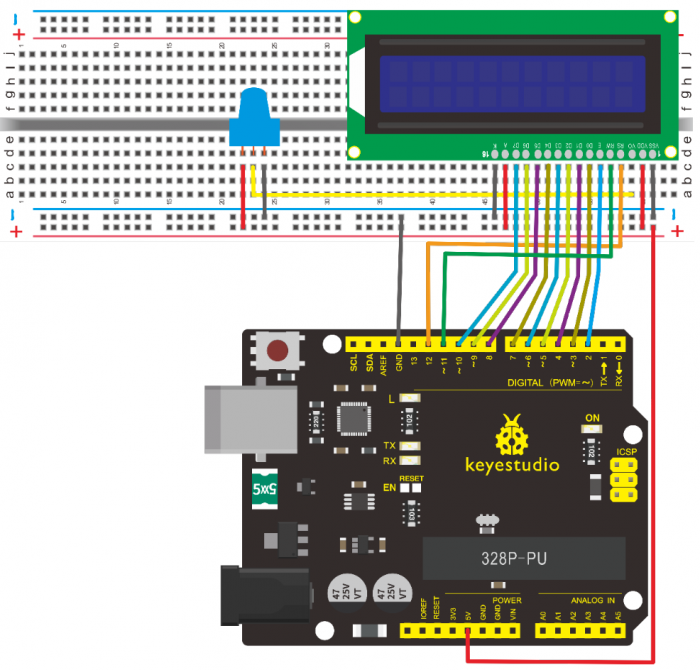

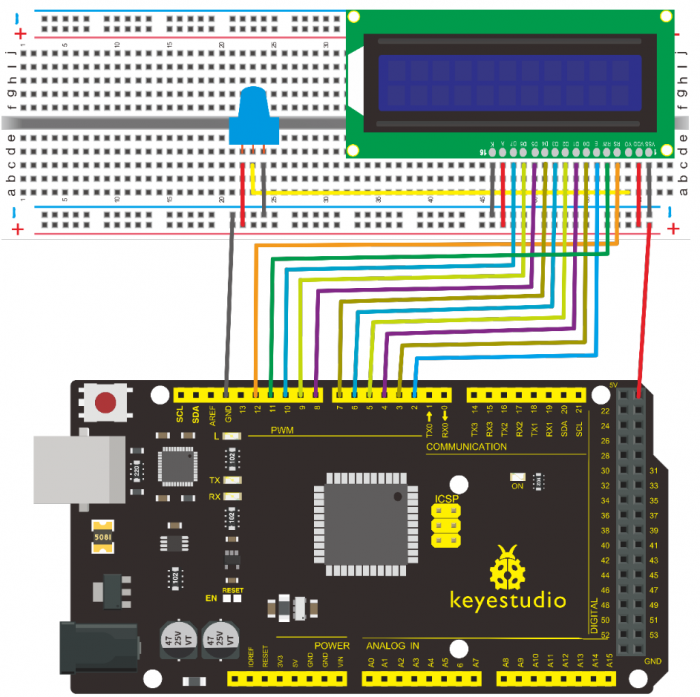

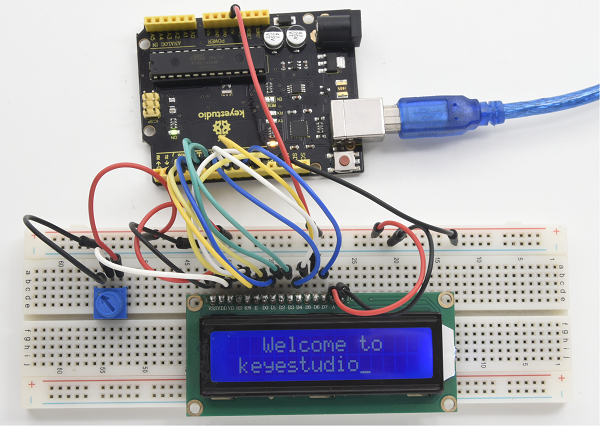

7.Connection

1602 can directly communicate with Arduino. According to the product manual, it has two connection methods, namely 8-bit connection and 4-bit connection.

8-bit Connection Method

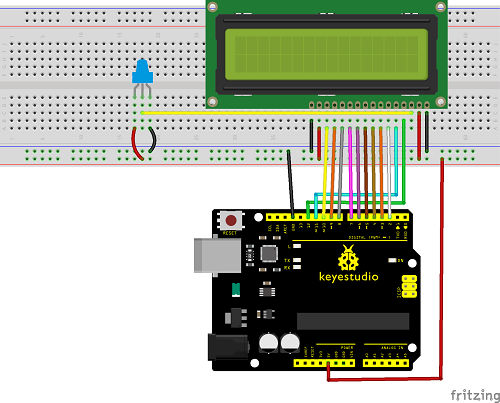

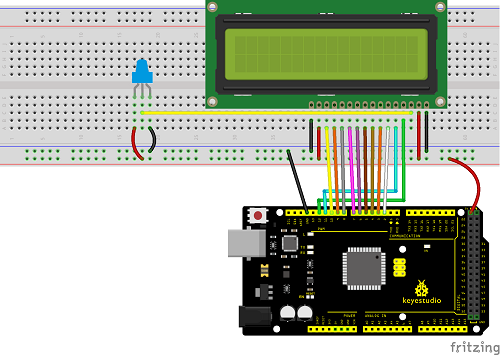

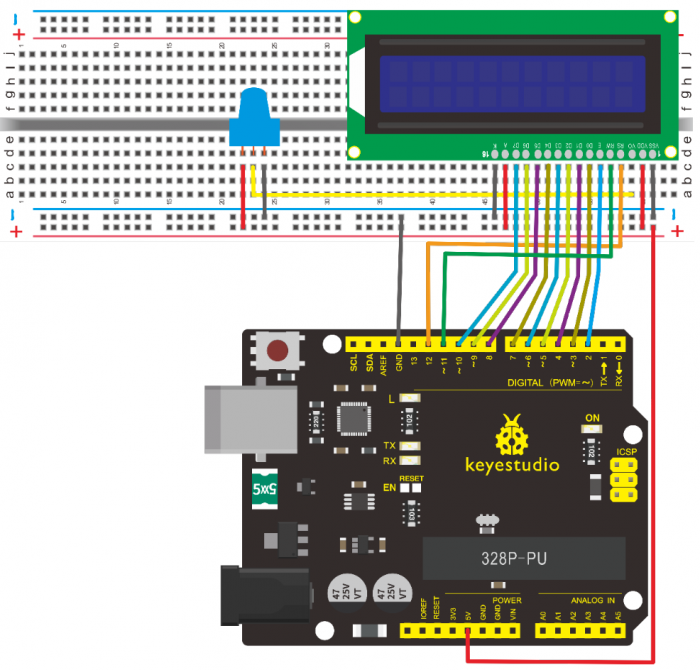

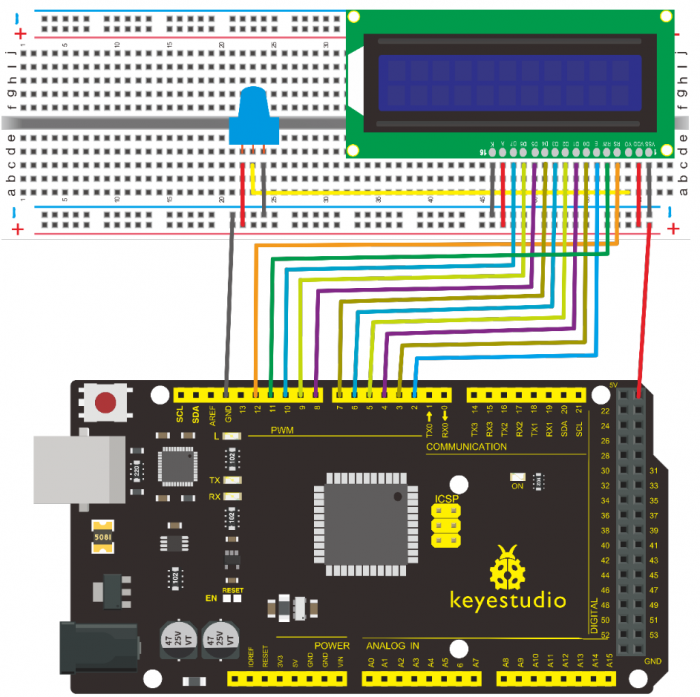

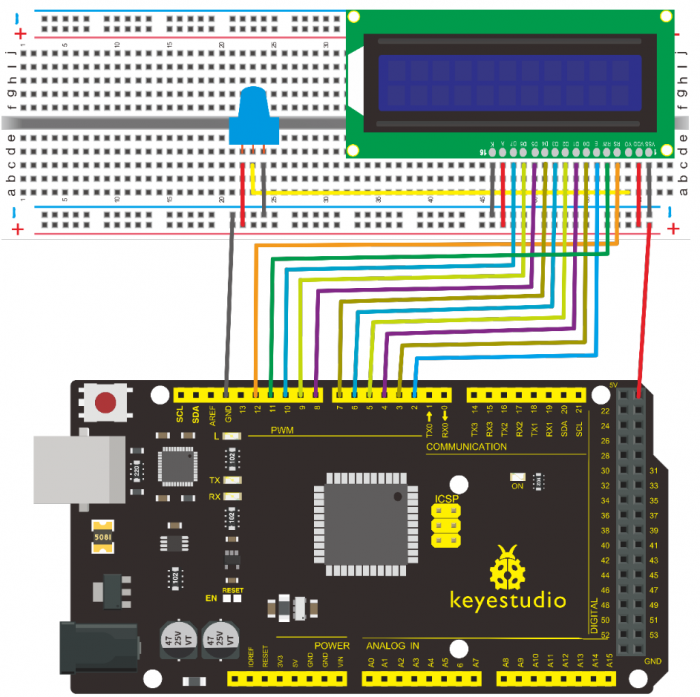

Connection for V4.0

Connection for 2560 R3

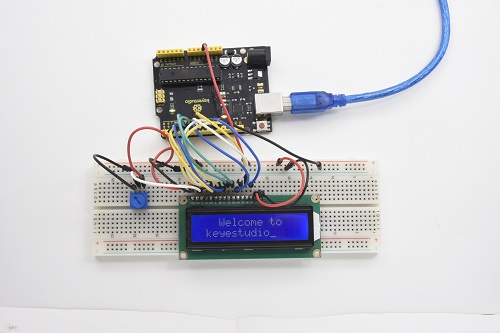

8.Sample Code A

/*

keyestudio super learning kit

Project 20.1

LCD1602

http//www.keyestudio.com

*/

int DI = 12;

int RW = 11;

int DB[] = {3, 4, 5, 6, 7, 8, 9, 10};// use array to select pin for bus

int Enable = 2;

void LcdCommandWrite(int value) {

// define all pins

int i = 0;

for (i=DB[0]; i <= DI; i++) // assign value for bus

{

digitalWrite(i,value & 01);// for 1602 LCD, it uses D7-D0( not D0-D7) for signal identification; here, it’s used for signal inversion.

value >>= 1;

}

digitalWrite(Enable,LOW);

delayMicroseconds(1);

digitalWrite(Enable,HIGH);

delayMicroseconds(1); // wait for 1ms

digitalWrite(Enable,LOW);

delayMicroseconds(1); // wait for 1ms

}

void LcdDataWrite(int value) {

// initialize all pins

int i = 0;

digitalWrite(DI, HIGH);

digitalWrite(RW, LOW);

for (i=DB[0]; i <= DB[7]; i++) {

digitalWrite(i,value & 01);

value >>= 1;

}

digitalWrite(Enable,LOW);

delayMicroseconds(1);

digitalWrite(Enable,HIGH);

delayMicroseconds(1);

digitalWrite(Enable,LOW);

delayMicroseconds(1); // wait for 1ms

}

void setup (void) {

int i = 0;

for (i=Enable; i <= DI; i++) {

pinMode(i,OUTPUT);

}

delay(100);

// initialize LCD after a brief pause

// for LCD control

LcdCommandWrite(0x38); // select as 8-bit interface, 2-line display, 5x7 character size

delay(64);

LcdCommandWrite(0x38); // select as 8-bit interface, 2-line display, 5x7 character size

delay(50);

LcdCommandWrite(0x38); // select as 8-bit interface, 2-line display, 5x7 character size

delay(20);

LcdCommandWrite(0x06); // set input mode

// auto-increment, no display of shifting

delay(20);

LcdCommandWrite(0x0E); // display setup

// turn on the monitor, cursor on, no flickering

delay(20);

LcdCommandWrite(0x01); // clear the scree, cursor position returns to 0

delay(100);

LcdCommandWrite(0x80); // display setup

// turn on the monitor, cursor on, no flickering

delay(20);

}

void loop (void) {

LcdCommandWrite(0x01); // clear the scree, cursor position returns to 0

delay(10);

LcdCommandWrite(0x80+3);

delay(10);

// write in welcome message

LcdDataWrite('W');

LcdDataWrite('e');

LcdDataWrite('l');

LcdDataWrite('c');

LcdDataWrite('o');

LcdDataWrite('m');

LcdDataWrite('e');

LcdDataWrite(' ');

LcdDataWrite('t');

LcdDataWrite('o');

delay(10);

LcdCommandWrite(0xc0+1); // set cursor position at second line, second position

delay(10);

LcdDataWrite('k');

LcdDataWrite('e');

LcdDataWrite('y');

LcdDataWrite('e');

LcdDataWrite('s');

LcdDataWrite('t');

LcdDataWrite('u');

LcdDataWrite('d');

LcdDataWrite('i');

LcdDataWrite('o');

delay(5000);

LcdCommandWrite(0x01); // clear the screen, cursor returns to 0

delay(10);

LcdDataWrite('I');

LcdDataWrite(' ');

LcdDataWrite('a');

LcdDataWrite('m');

LcdDataWrite(' ');

LcdDataWrite('h');

LcdDataWrite('u');

LcdDataWrite('n');

LcdDataWrite('t');

LcdDataWrite('e');

LcdDataWrite('r');

delay(3000);

LcdCommandWrite(0x02); // set mode as new characters replay old ones, where there is no new ones remain the same

delay(10);

LcdCommandWrite(0x80+5); // set cursor position at first line, sixth position

delay(10);

LcdDataWrite('t');

LcdDataWrite('h');

LcdDataWrite('e');

LcdDataWrite(' ');

LcdDataWrite('w');

LcdDataWrite('o');

LcdDataWrite('r');

LcdDataWrite('l');

LcdDataWrite('d');

delay(5000);

}

//////////////////////////////////////////////////////////

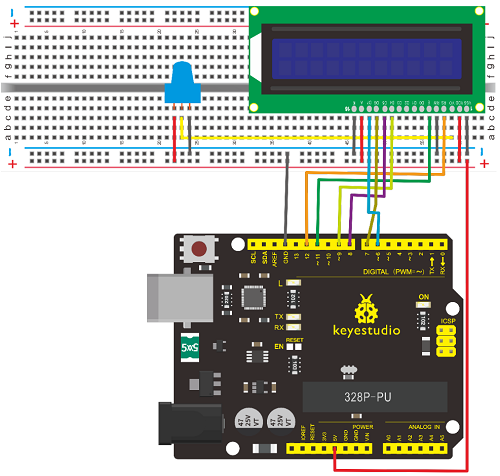

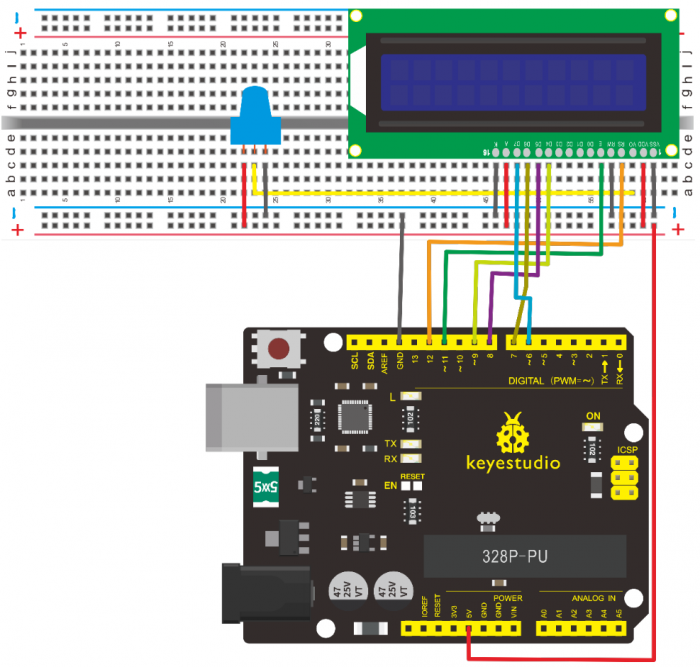

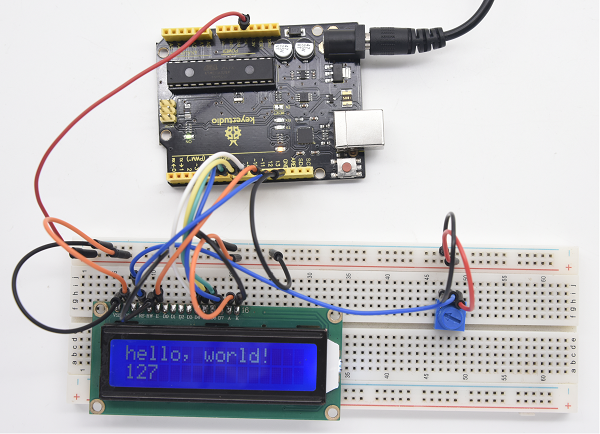

4-bit Connection Method

When using this module, 8-bit connection uses all the digital pins of the Arduino, leaving no pin for sensors. What then? You can use 4-bit connection.

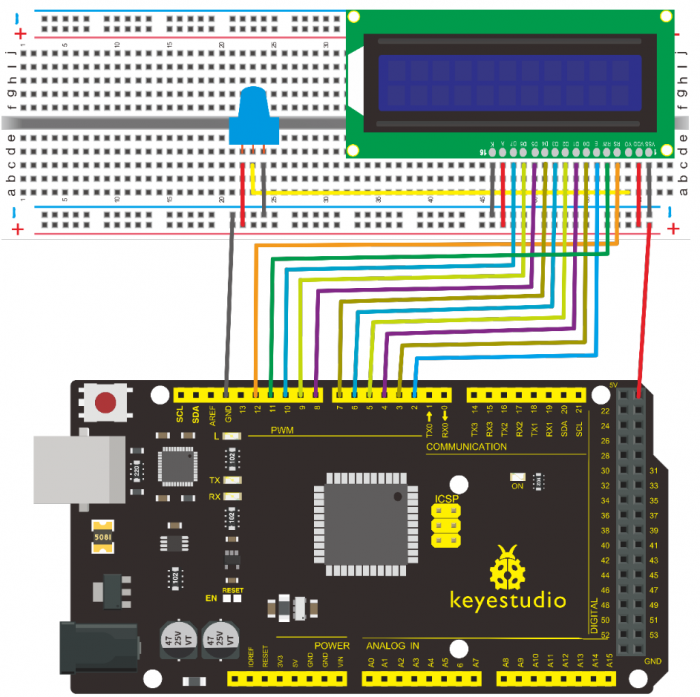

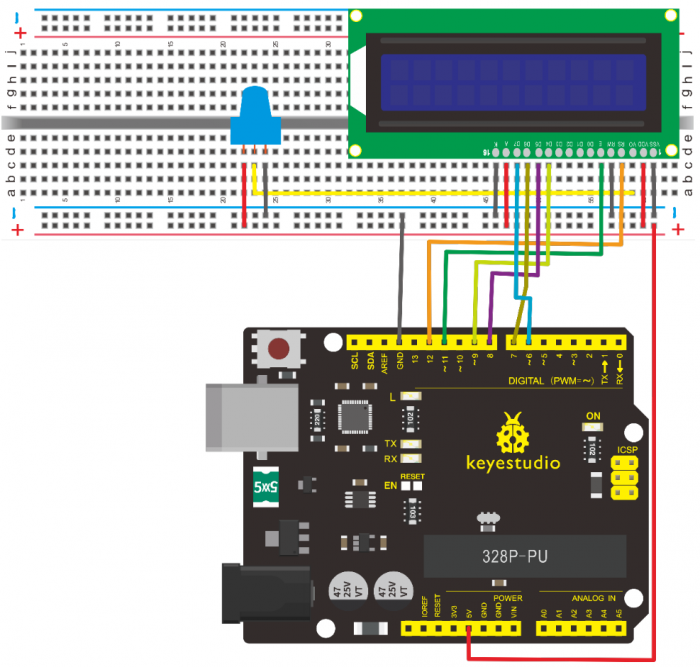

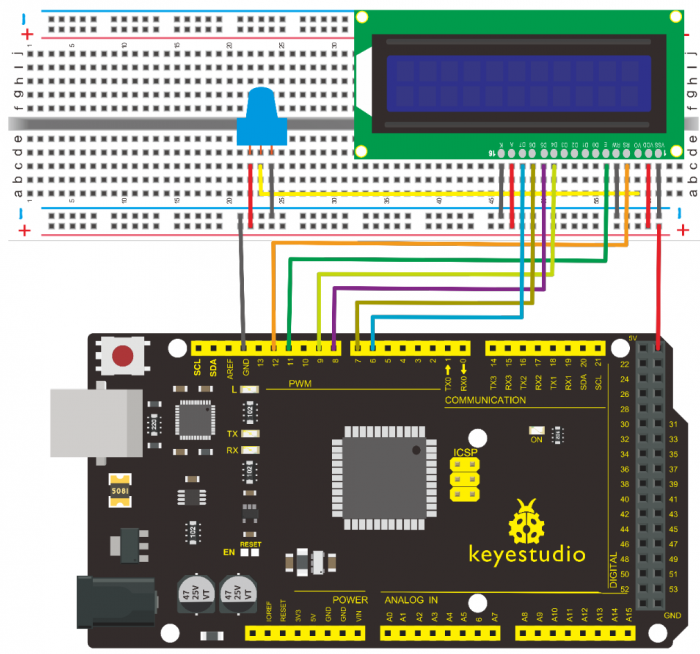

Connection for V4.0

Connection for 2560 R3

After the connection, upload below code to the controller board and see how it goes.

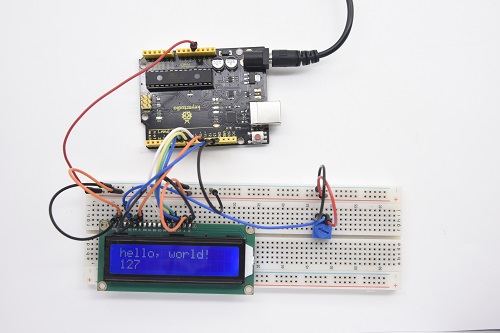

9.Sample Code B

/*

keyestudio super learning kit

Project 20.2

LCD1602

http//www.keyestudio.com

*/

/* LCD RS pin to digital pin 12

* LCD Enable pin to digital pin 11

* LCD D4 pin to digital pin 9

* LCD D5 pin to digital pin 8

* LCD D6 pin to digital pin 7

* LCD D7 pin to digital pin 6

* LCD R/W pin to ground

* LCD VSS pin to ground

* LCD VCC pin to 5V

* 10K resistor

* ends to +5V and ground

* wiper to LCD VO pin (pin 3)

This example code is in the public domain.

http//www.arduino.cc/en/Tutorial/LiquidCrystal

*/

// include the library code

#include <LiquidCrystal.h>

// initialize the library with the numbers of the interface pins

LiquidCrystal lcd(12, 11, 9, 8, 7, 6);

void setup() {

// set up the LCD's number of columns and rows

lcd.begin(16, 2);

// Print a message to the LCD.

lcd.print("hello, world!");

}

void loop() {

// set the cursor to column 0, line 1

// (note line 1 is the second row, since counting begins with 0)

lcd.setCursor(0, 1);

// print the number of seconds since reset

lcd.print(millis() / 1000);

}

//////////////////////////////////////////////////////////

10. Test Result

Project 21: Servo Control

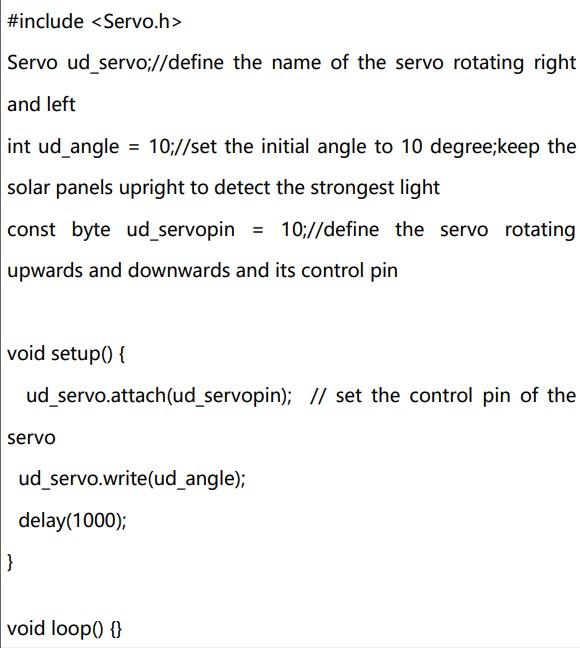

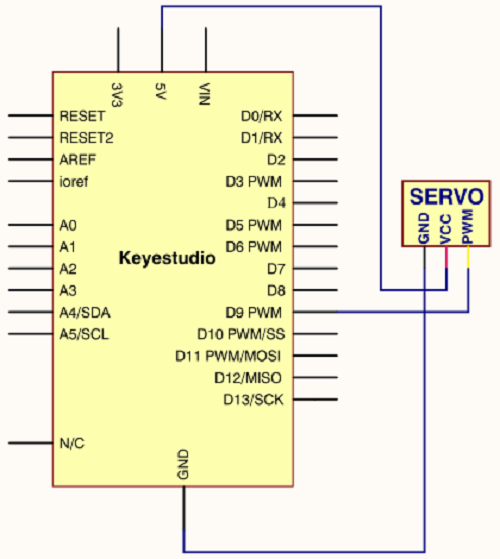

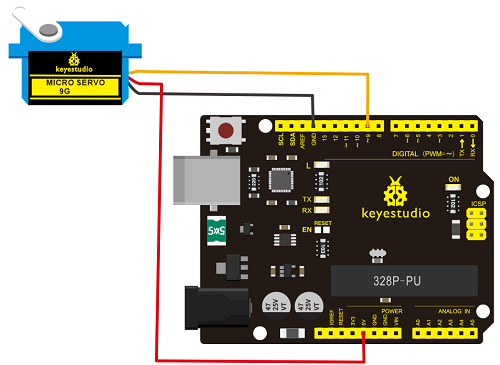

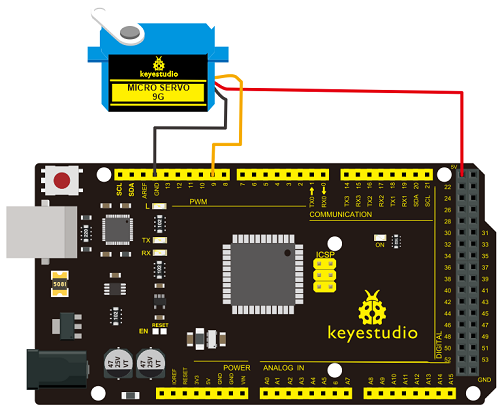

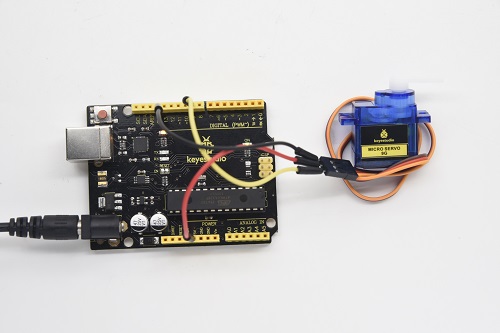

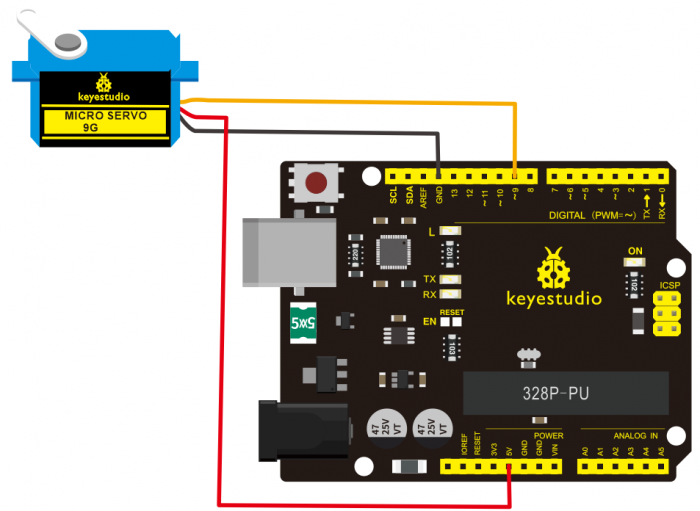

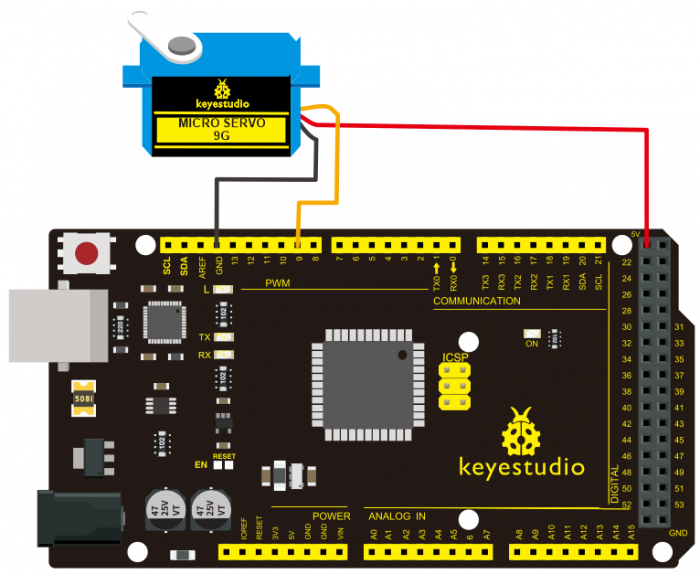

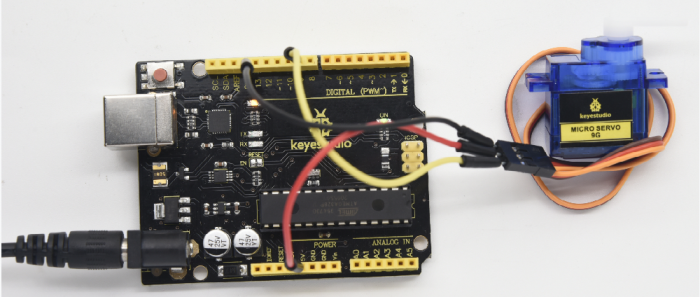

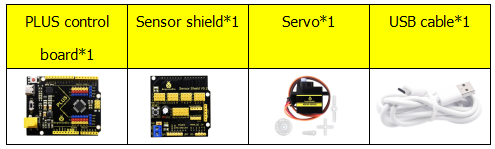

1.Introduction

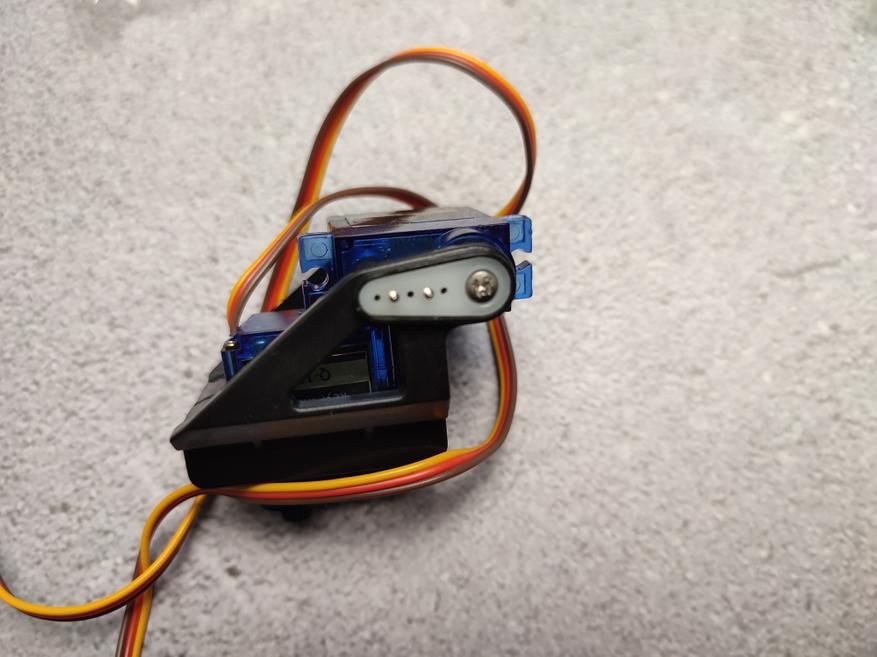

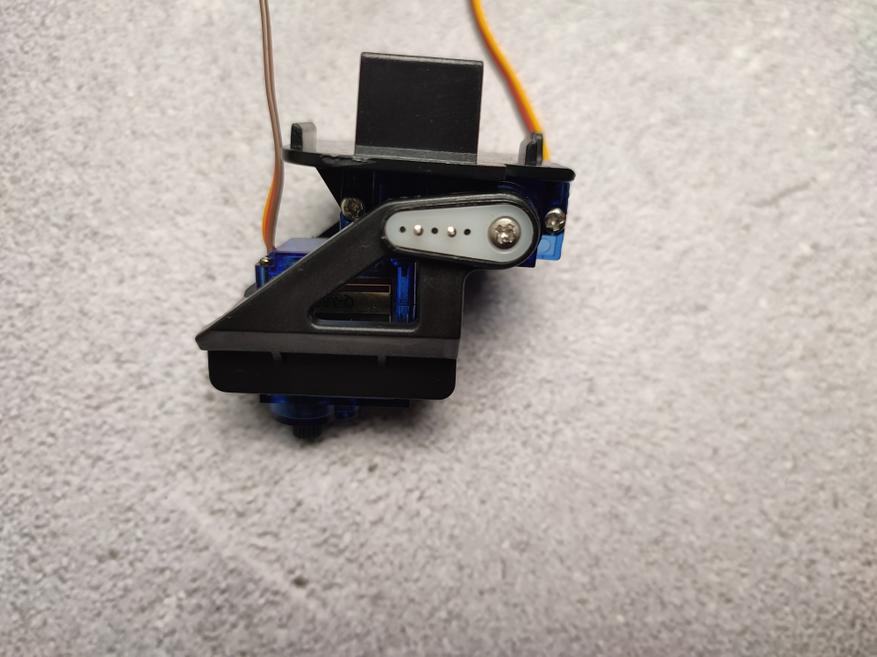

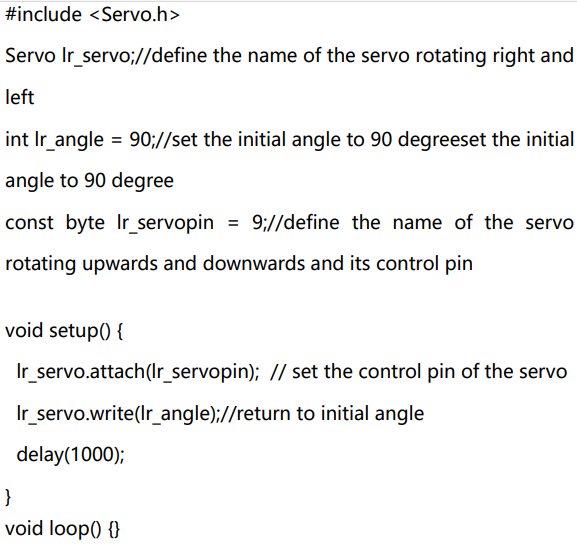

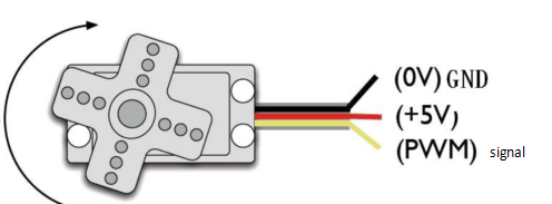

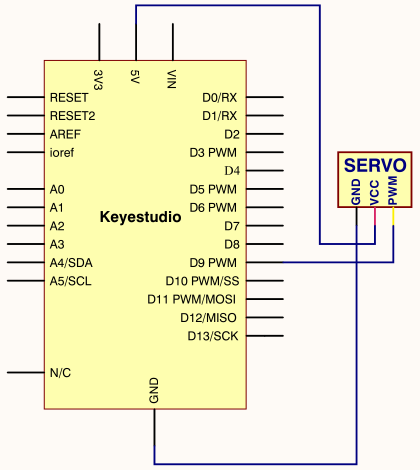

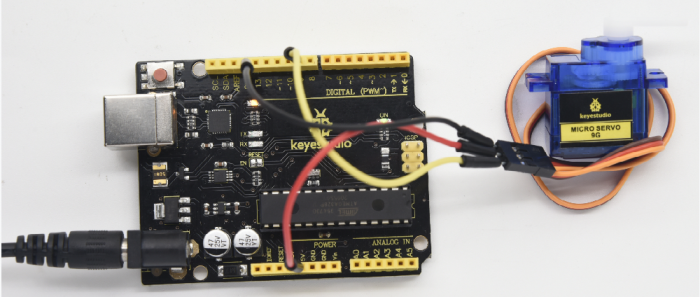

Servomotor is a position control rotary actuator. It mainly consists of housing, circuit board, core-less motor, gear and position sensor. For this lesson, we will introduce servo to you.

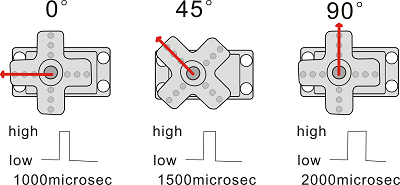

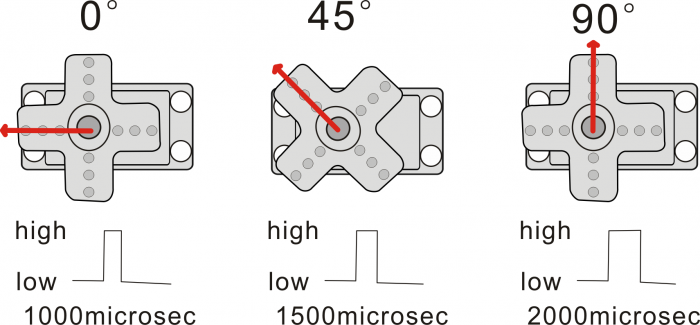

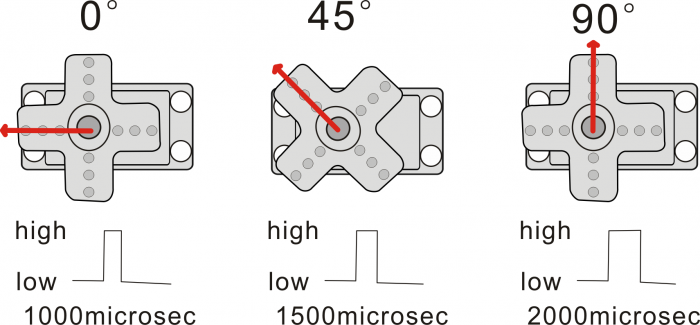

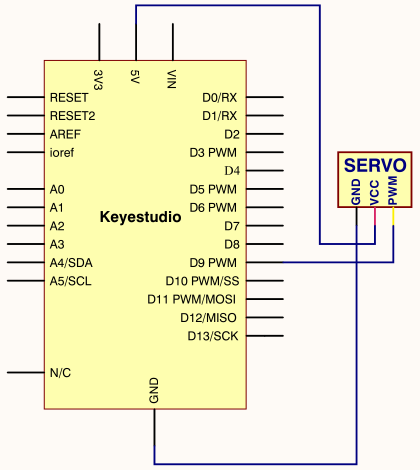

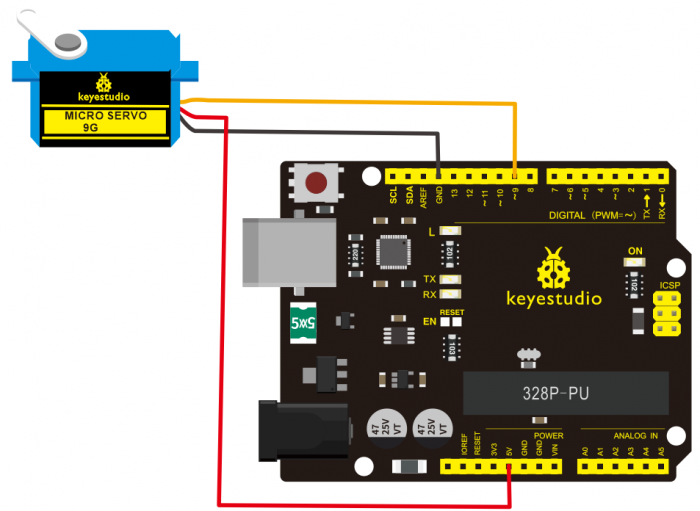

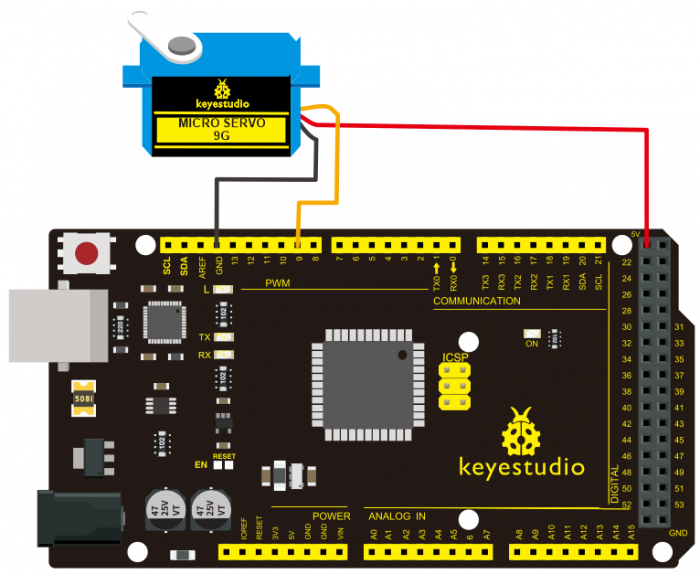

2.Working Principle

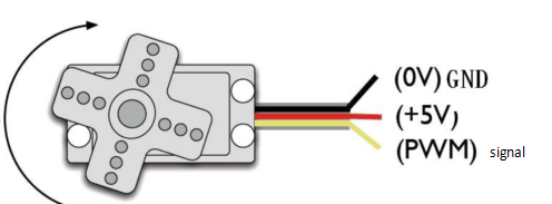

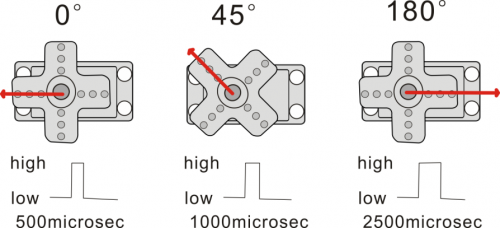

The MCU outputs a signal to the servomotor. The motor has a built-in reference circuit that gives out reference signal, cycle of 20ms and width of 1.5ms. The motor compares the acquired DC bias voltage to the voltage of the potentiometer and outputs a voltage difference. The IC on the circuit board will decide the rotate direction accordingly and drive the core-less motor. The gear then pass the force to the shaft. The sensor will determine whether it has reached the commanded position according to the feedback signal.

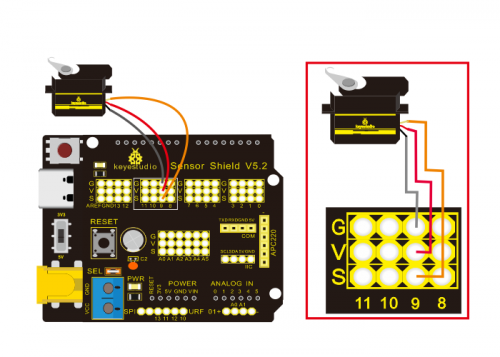

Servomotors are used in control systems that require to have and maintain different angles. When the motor speed is definite, the gear will drive the potentiometer to rotate. When the voltage difference reduces to zero, the motor stops. Normally, the rotation angle range is among 0-180 degrees.